Lactobacillus and method for producing D-lactic acid by fermenting using lactobacillus

A kind of Lactobacillus and lactic acid technology, applied in the field of Lactobacillus and utilizing its fermentation to produce D-lactic acid, can solve the problems such as not involving the application of Lactobacillus pentosus, and achieve the effect of promoting nutritional needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Put 0.1 g of lyophilized powder of Lactobacillus DMDL9010 into 5 mL of seed medium, and culture it statically at 30°C for 24 hours to make the first seed liquid;

[0043] (2) Put the first activation solution into the seed medium at a volume ratio of 10:100, and culture it statically at 30°C for 24 hours to make the second seed solution;

[0044] (3) Put the second activation solution into the seed medium at a volume ratio of 10:100, and culture it statically at 30°C for 24 hours to make the third seed solution;

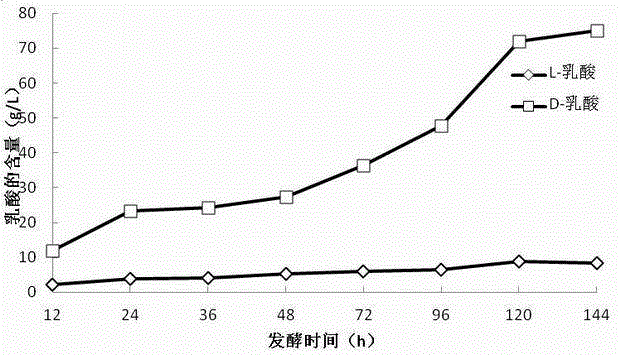

[0045] (4) Put the third seed solution into the fermentation medium at a volume ratio of 5:100, and cultivate it at 30°C in a fermenter with a stirring speed of 100~150rpm. Add a total of 50g / L of sterilized CaCO in 5 times 3 , the fermentation time is 144h.

[0046] The formula of the seed medium is: glucose 20g / L, peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, sodium acetate 2g / L, triamine citrate 2g / L, Tween 80 1mL / L, MgSO 4 .7H 2 O 0.2 g / L,...

Embodiment 2

[0054] (1) Place 0.2 g of lyophilized powder of Lactobacillus DMDL9010 in 6 mL of seed medium, and culture it statically at 35°C for 20 hours to make the first seed liquid;

[0055] (2) Put the first activation solution into the seed medium at a ratio of 10:100 by volume, and culture it statically at 35°C for 24 hours to make the second seed solution;

[0056] (3) Put the second activation solution into the seed medium at a ratio of 10:100 by volume, and culture it statically at 35°C for 24 hours to make the third seed solution;

[0057] (4) Put the third seed liquid into the fermentation medium with a volume ratio of 8:100, and cultivate it at 35°C in a fermenter with a stirring speed of 100~150rpm. Add a total of 20g / L of sterilized CaCO2 in 2 times 3 After every 24 hours of fermentation, sterilized 40% (wt) ammonia water was added at a flow rate of 1.0ml / min, the pH was adjusted to 6.8, and the fermentation time was 120 hours.

[0058] The formula of the seed medium is: g...

Embodiment 3

[0064] (1) Put 0.3 g of lyophilized powder of Lactobacillus DMDL9010 into 7 mL of seed medium, and culture it statically at 30°C for 24 hours to make the first seed liquid;

[0065] (2) Put the first activation solution into the seed medium at a volume ratio of 10:100, and culture it statically at 30°C for 24 hours to make the second seed solution;

[0066] (3) Put the second activation solution into the seed medium at a volume ratio of 10:100, and culture it statically at 30°C for 24 hours to make the third seed solution;

[0067] (4) Put the third seed solution into the fermentation medium at a volume ratio of 5:100, and cultivate it at 30°C in a fermenter with a stirring speed of 100~150rpm. Add a total of 30g / L of sterilized Ca(OH) in 3 times 2 After every 24 hours of fermentation, sterilized 40% (wt) NaOH solution was added at a flow rate of 1.0 ml / min to adjust the pH to 7.0, and the fermentation time was 144 hours.

[0068] The formula of the seed medium is: glucose 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com