Vortex type bubble spinning device

A bubble spinning and vortex-type technology, which is applied in stretch spinning, textile and papermaking, filament/thread forming, etc. It can solve the problems of low output, easy to block needles, and great impact on performance, and achieve high production efficiency. , low production cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

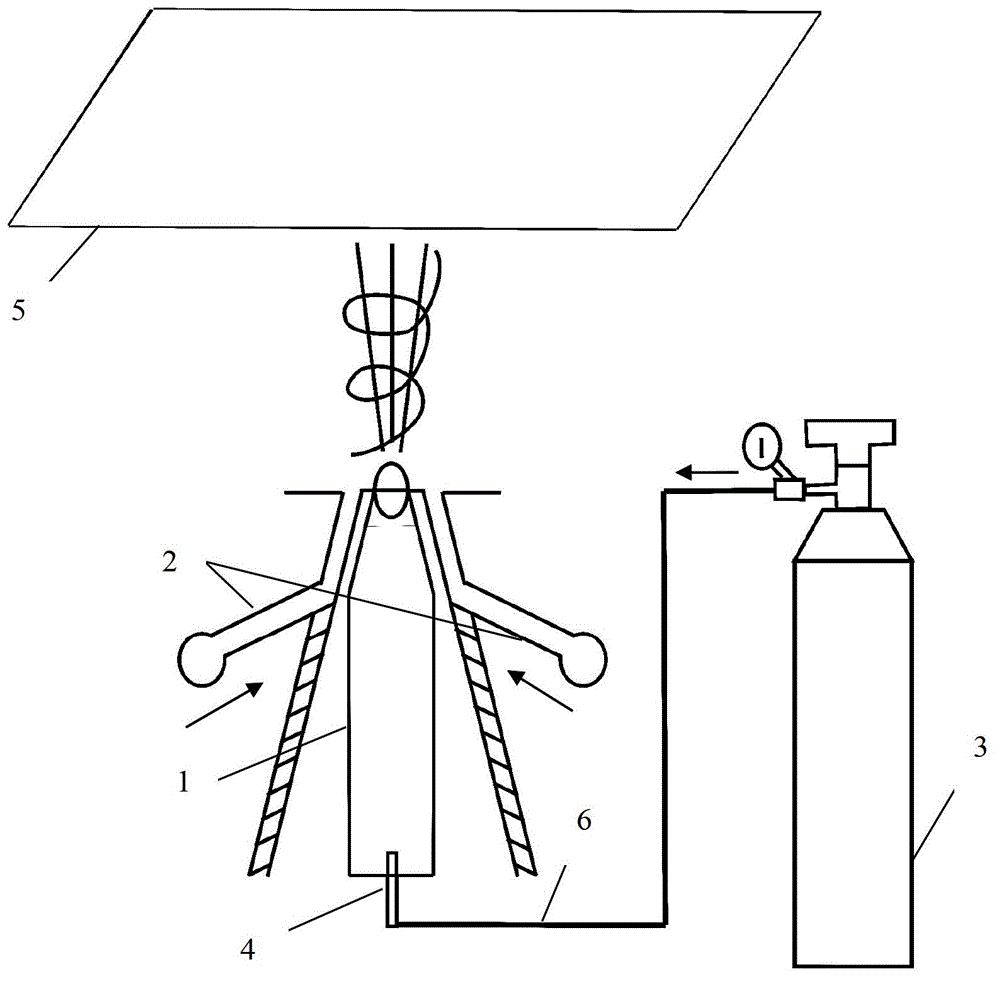

[0035] like figure 1 As shown, the vortex air bubble spinning device disclosed in this embodiment includes a liquid storage tank 1, an air pump 3, a vertically upward nozzle 4 arranged on the bottom surface of the liquid storage tank 1, and a flat plate directly above the liquid storage tank 1. Shaped receiving plate 5, air duct 6. The upper end of the liquid reservoir 1 is open. The nozzle 4 is connected to the air pump 3 through the air guide pipe 6 . The place where the air guide tube 6 is connected to the air pump 3 is higher than the liquid level of the liquid storage tank 1 . Two sides of the liquid storage pool 1 are respectively provided with a hot air jetting groove 2, and the two hot air jetting slots 2 are arranged in a symmetrical inclined shape. The air outlets of the two hot air jet grooves 2 are directed towards the upper end of the liquid reservoir 1 where the jet stream is ejected. The distance adjustment range between the receiving surface of the receivin...

Embodiment 2

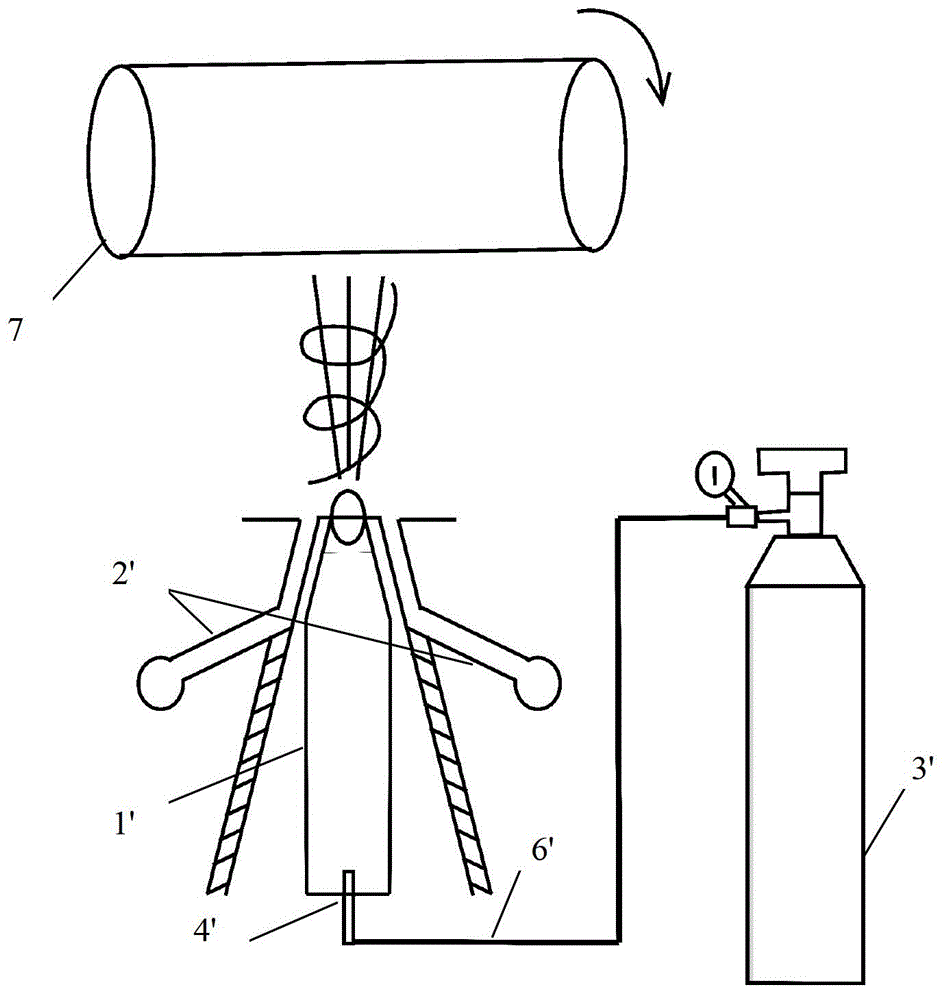

[0038] like figure 2 As shown, the vortex air bubble spinning device disclosed in this embodiment includes a liquid storage tank 1', an air pump 3', a nozzle 4' arranged on the bottom of the liquid storage tank 1' and vertically upward, and a nozzle 4' located in the liquid storage tank 1'. 'Roller 7 directly above, air duct 6'. The upper end of the liquid reservoir 1 is open. The nozzle 4' is connected with the air pump 3' through the air duct 6'. The connection between the air duct 6' and the air pump 3' is higher than the liquid level of the liquid reservoir 1'. Two sides of the liquid reservoir 1' are respectively provided with a hot air jet groove 2', and the two hot air jet slots 2' are arranged in a symmetrical inclined shape. The air outlets of the two hot air jet grooves 2' are directed towards the upper end of the liquid reservoir 1' where the jet stream is ejected. The adjustment range of the distance between the receiving surface of the drum 7 and the upper en...

Embodiment 3

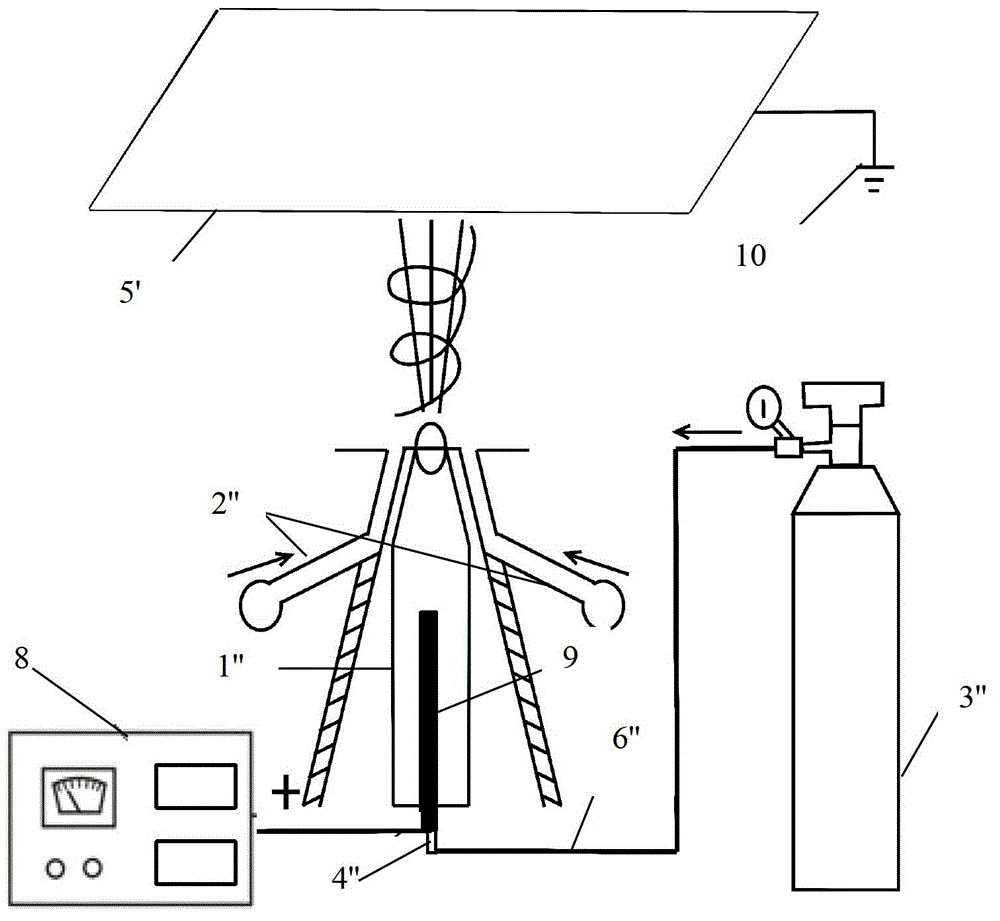

[0041] like image 3As shown, the vortex air bubble spinning device disclosed in this embodiment includes a liquid storage tank 1', an air pump 3", a nozzle 4" located on the bottom surface of the liquid storage tank 1" and vertically upward, and a nozzle 4" located in the liquid storage tank 1". "The plate-shaped receiving pole plate 5' directly above, the air duct 6", the high-voltage electrostatic generator 8, the metal wire 9, the grounding electrode 10 connected with the receiving pole plate 5'. The upper end of the liquid reservoir 1 "is open. The nozzle 4" is connected to the air pump 3" through the air pipe 6". The part where the air pipe 6" is connected to the air pump 3" is higher than the liquid level of the liquid storage tank 1". One end of metal wire 9 is connected with high-voltage electrostatic generator 8, and the other end extends into liquid reservoir 1 ". Both sides of liquid reservoir 1 " are respectively provided with a hot air jet groove 2 ", and these t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com