Coal-gas combined efficient low-emission grate firing combustion apparatus and technology

A combustion device and combined technology, which is applied in the direction of combustion, combustion equipment, lighting and heating equipment using gaseous fuel and powder fuel, can solve the problems of poor industrial applicability, less reducing gas, and affect boiler output, etc., to reduce conversion , Improve the combustion efficiency, the effect of improving the combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

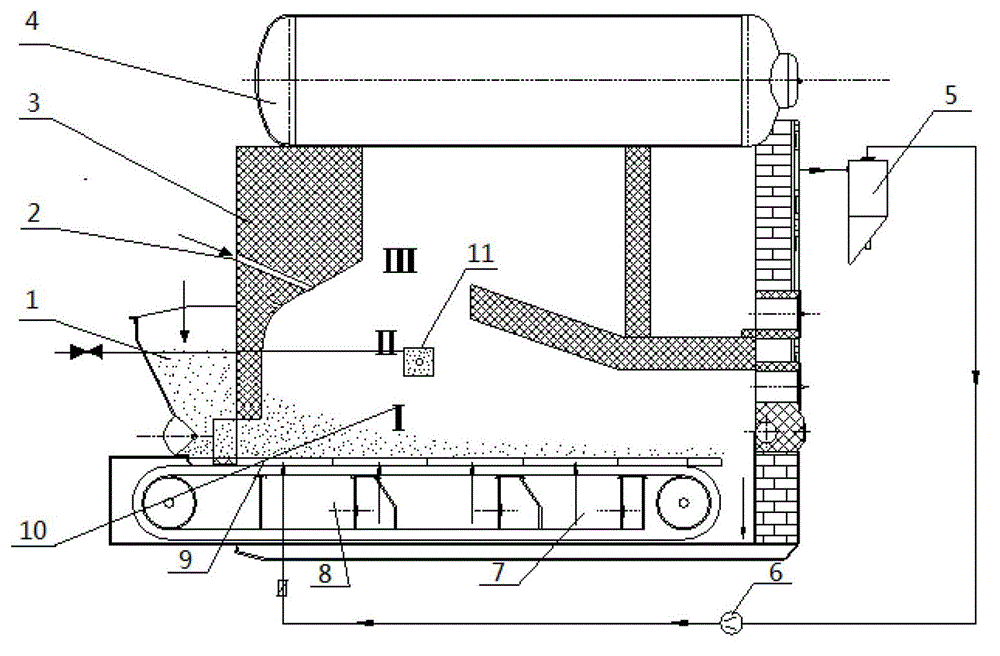

[0015] A coal-fired gas combination type high-efficiency and low-emission layer combustion combustion device, including a combustion chamber 10 and a fire grate 9. The combustion chamber 10 is divided into a main combustion area I, a reburning area II above the main combustion area I, and an upper area near the combustion chamber 10. burnout area III of the mouth, the combustion chamber 10 is provided with a gas nozzle 11 communicating with the middle position of the reburning area II of the combustion chamber 10, and a burnout air nozzle 2 communicating with the lower part of the burnout area III, and the grate 9 is close to A flue gas recirculation air chamber 8 is arranged at the bottom of part of the feed inlet, and the flue gas recirculation air chamber 8 communicates with the tail gas outlet of the combustion chamber 10 through the circulation fan 6 and the gas-solid separator 5 . A hopper 1 is arranged at the feed inlet, and a gas nozzle 11 and an overfired air nozzle 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com