Transparent conductive film layer for capacitive touch screen

A capacitive touch screen, transparent conductive film technology, applied to the conductive layer on the insulating carrier, cable/conductor manufacturing, circuit and other directions, can solve the problems of expensive ITO film, difficult to protect, fall off, etc., to improve product yield and reliability Sexuality, avoid easy falling off and damage, reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

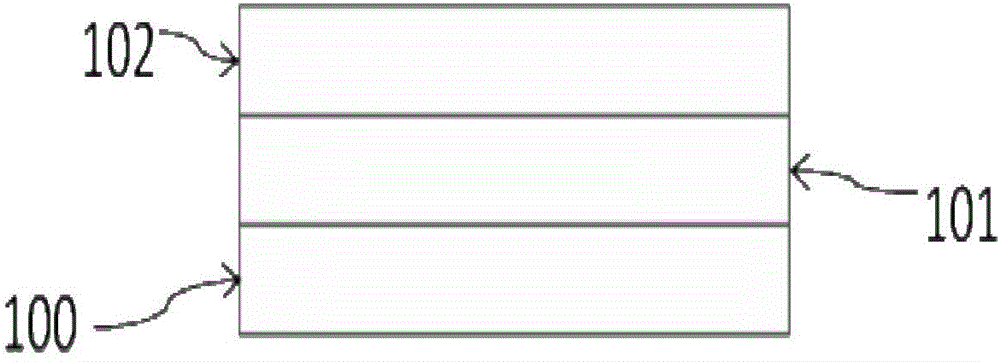

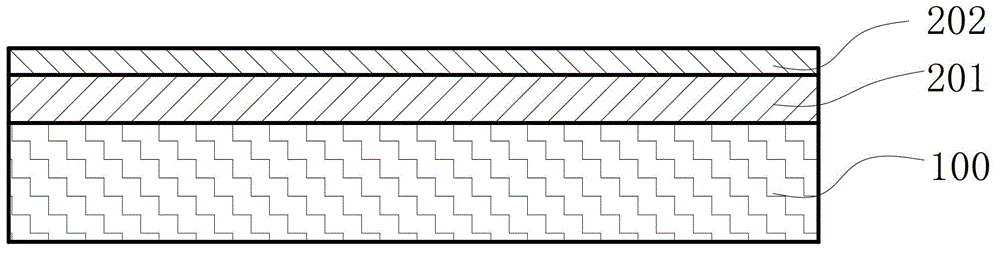

[0077] A transparent conductive film layer for a capacitive touch screen, comprising a substrate 100, a graphene transparent conductive layer 201 attached to the substrate, and a transparent conductive oxide film layer 202 deposited on the graphene material;

[0078] Wherein, the thickness of the graphene transparent conductive layer 201 is 0.3nm; the graphene transparent conductive layer 201 is a monoatomic layer; the optical transmittance of the visible light of the graphene transparent conductive layer 201 is 95%;

[0079] The transparent conductive oxide film layer 202 is an AZO film with a thickness of 100 nm; the substrate 100 is a glass substrate with a thickness of 1 mm; image 3 It is a schematic structural view of the transparent conductive film layer used in the capacitive touch screen described in Embodiment 1.

[0080] Preparation

[0081] The preparation method of the transparent conductive film layer of the capacitive touch screen comprises:

[0082] (1) Using...

Embodiment 2

[0087] A transparent conductive film layer for a capacitive touch screen, comprising a substrate 100, a graphene transparent conductive layer 201 attached to the substrate, and a transparent conductive oxide film layer 202 deposited on the graphene material;

[0088] Wherein, the thickness of the graphene transparent conductive layer 201 is 1 nm; the number of atomic layers of the graphene transparent conductive layer 201 is 3 layers; the optical transmittance of visible light of the graphene transparent conductive layer 201 is ≥ 89%;

[0089] The transparent conductive oxide film layer 202 is an AZO thin film with a thickness of 100 nm; the substrate 100 is a glass substrate with a thickness of 2 mm.

[0090] Preparation

[0091] A preparation method of a transparent conductive film layer of a capacitive touch screen, comprising:

[0092] (1) Using the method disclosed in CN102220566A to prepare a graphene film, specifically: placing the metal substrate in a vacuum tube furn...

Embodiment 3

[0097] A transparent conductive film layer for a capacitive touch screen, comprising a substrate 100, a graphene transparent conductive layer 201 attached to the substrate, and a transparent conductive oxide film layer 202 deposited on the graphene material;

[0098] Wherein, the thickness of the graphene transparent conductive layer 201 is 1.5nm; the number of atomic layers of the graphene transparent conductive layer 201 is 5 layers; the optical transmittance of the visible light of the graphene transparent conductive layer 201 is ≥ 87%;

[0099] The transparent conductive oxide film layer 202 is an FTO film with a thickness of 100 nm; the substrate 100 is a glass substrate with a thickness of 0.3 mm.

[0100] Preparation

[0101] A preparation method of a transparent conductive film layer of a capacitive touch screen, comprising:

[0102] (1) Using the method disclosed in CN102220566A to prepare a graphene film, specifically: placing the metal substrate in a vacuum tube fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com