Copper-coated plastic wire production process and copper-coated plastic wire production line

A production line, copper clad technology, used in coaxial cables/analog cables, manufacturing coaxial cables, waveguide-type devices, etc., can solve problems such as increasing the complexity of processing, and achieve the effects of easy transportation, reduced load, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

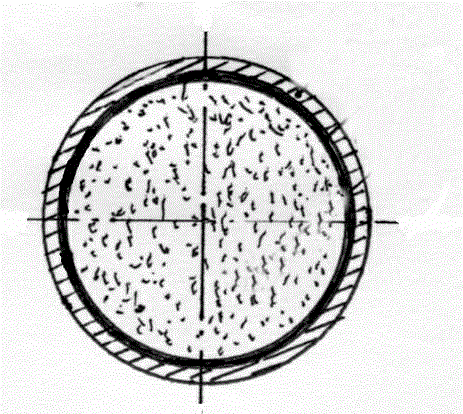

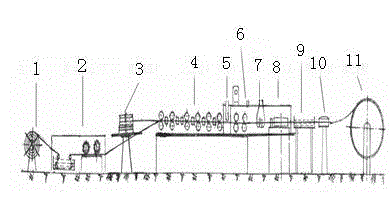

[0030] Taking the production of copper-clad plastic wire with an outer diameter of φ13.1mm and a copper layer thickness of 0.3mm as an example, it is explained in figure 2 The process of producing copper clad plastic wire on the production line shown.

[0031] 1. Prepare the copper strip: the diameter of the copper strip after coating should be 0.6mm larger than the specified value, so that the plastic wire will not be burned when welding the longitudinal seam of the copper pipe. Therefore, a copper strip with a thickness of 0.3mm and a width of 13.7×3.14=43mm is selected. The copper strip is placed on the material tray (1), and after cleaning and scrubbing (2), surface oil stains and oxide layers are removed, and the surface roughness of the copper strip is increased to facilitate hot-melt adhesive bonding.

[0032] 2. Purchase or self-produce high-density polyethylene plastic wire with a diameter of φ11.5mm, wrap TF-30XX hot melt adhesive film with a thickness of 0.1mm on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com