Wood vinegar acidic culture substrate and compounding process thereof

A technology of cultivation substrate and wood vinegar, applied in cultivation, soilless cultivation, wood processing tools and other directions, to achieve the effects of nutrient balance, promoting flowering and prolonging flowering period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

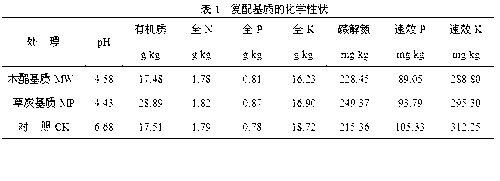

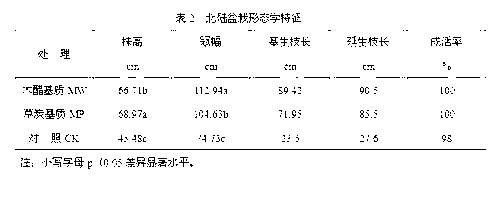

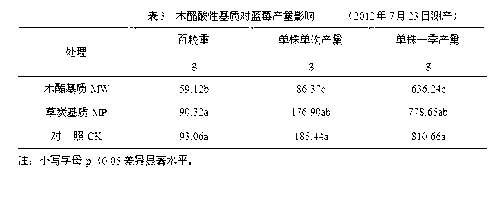

Embodiment 1

[0029] Larix bark, flattened and air-dried, breaking up large pieces of bark, taking 0.5m 3 , add 5000L of 5% ethanol solution, stir and mix evenly, heat to 60°C and let it stand for 18 hours, drain the water, air-dry and pulverize, and mix with natural air-dried garden soil at a volume ratio of 1:1 to form a mixed matrix; mass percent Dissolve 1.5 g of disodium edetate with a content of 98% in 100 ml of distilled water, dissolve 1 g of ferrous sulfate with a mass percentage of 99% in 45 ml of distilled water, mix with disodium edetate, weigh 2.6 g of urea with a mass percentage of 99%, 10.4 g of diammonium hydrogen phosphate with a mass percentage of 99%, are dissolved in a mixed solution of disodium edetate-ferrous sulfate, and 98% of the mass percentage is added Sulfuric acid 34.2ml, get corn stalk wood vinegar 800ml and above-mentioned nutrient solution and mix and compound to be wood vinegar nutrient solution, with watering can wood vinegar nutrient solution 50ml is stirr...

Embodiment 2

[0031] Larix bark, flattened and air-dried, breaking up large pieces of bark, taking 0.5m 3 , add 5000L of 5% ethanol solution, stir and mix evenly, heat to 60°C and let it stand for 18 hours, drain the water, air-dry and pulverize, and mix with natural air-dried garden soil at a volume ratio of 1:1 to form a mixed matrix; mass percent Dissolve 1.5 g of disodium edetate with a content of 98% in 100 ml of distilled water, dissolve 1 g of ferrous sulfate with a mass percentage of 99% in 45 ml of distilled water, mix with disodium edetate, weigh 2.6 g of urea with a mass percentage of 99%, 10.4 g of diammonium hydrogen phosphate with a mass percentage of 99%, are dissolved in a mixed solution of disodium edetate-ferrous sulfate, and 98% of the mass percentage is added Sulfuric acid 34.2ml, get corn stalk wood vinegar 800ml and above-mentioned nutrient solution and mix and compound to be wood vinegar nutrient solution, with watering can wood vinegar nutrient solution 80ml is stirr...

Embodiment 3

[0033] Larix bark, flattened and air-dried, breaking up large pieces of bark, taking 0.5m 3 , add 5000L of 5% ethanol solution, stir and mix evenly, heat to 60°C and let it stand for 18 hours, drain the water, air-dry and pulverize, and mix with natural air-dried garden soil at a volume ratio of 1:1 to form a mixed matrix; mass percent Dissolve 1.5 g of disodium edetate with a content of 98% in 100 ml of distilled water, dissolve 1 g of ferrous sulfate with a mass percentage of 99% in 45 ml of distilled water, mix with disodium edetate, weigh 2.6 g of urea with a mass percentage of 99%, 10.4 g of diammonium hydrogen phosphate with a mass percentage of 99%, are dissolved in a mixed solution of disodium edetate-ferrous sulfate, and 98% of the mass percentage is added Sulfuric acid 34.2ml, get corn stalk wood vinegar 800ml and above-mentioned nutrient solution and mix and compound to be wood vinegar nutrient solution, with watering can wood vinegar nutrient solution 100ml is stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com