Production method of biological fish meal through microbial fermentation

A technology for microbial fermentation and fermentation substrates, applied in animal feed, animal feed, applications, etc., can solve the problems of poor palatability of plant protein sources, unbalanced amino acid composition, and unsatisfactory application effects, so as to improve immunity, The effect of reducing disease and improving digestive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

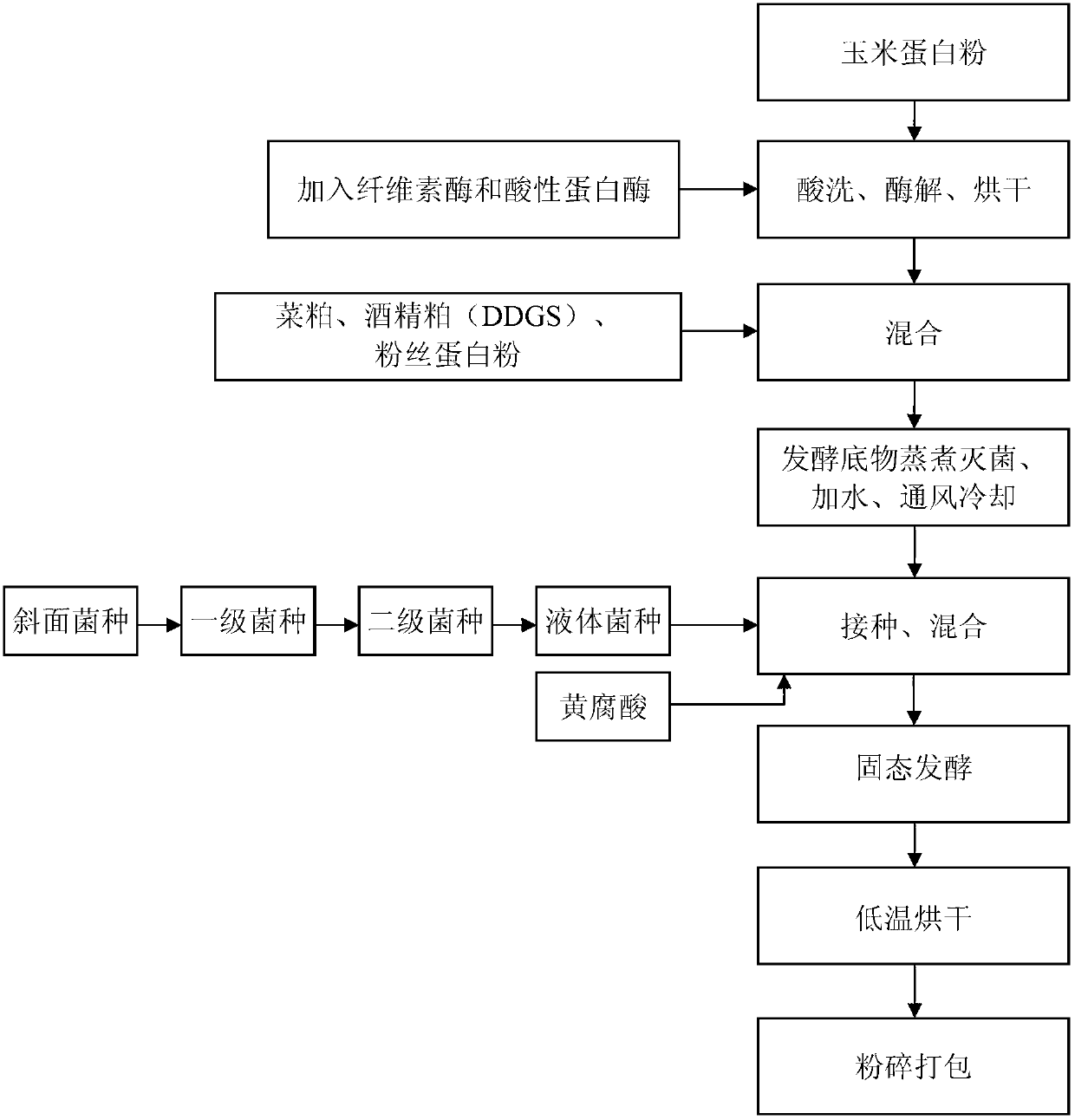

[0058] see figure 1 , prepare the biological fish meal of the present embodiment according to the following method:

[0059] 1. Weigh 500kg of corn gluten powder, 50kg of rapeseed meal, 50kg of alcohol meal DDGS, and 400kg of vermicelli protein powder.

[0060] 2. Pickling and enzymatic hydrolysis of corn gluten powder, the specific method is as follows:

[0061] A. Enzymolysis: Pour 600kg of corn gluten powder into a 5000L enzymolysis tank, add water and mix materials according to the ratio of material to water 1:5, then adjust the pH to 4.8 with 0.2mol / L hydrochloric acid, and dissolve the substrate liquid Heat to 52°C, add cellulase and acid protease according to the dosage of 30U / g and 5000U / g, and enzymatically hydrolyze at constant temperature for 60min;

[0062] B. Pickling: adjust the pH of the enzymolyzed substrate liquid to 3.8 with 0.2mol / L hydrochloric acid, stir at 80r / min for 60min at 31°C, centrifuge after the protein aggregates and precipitate, and remove the...

Embodiment 2

[0094] see figure 1 , prepare the biological fish meal of the present embodiment according to the following method:

[0095] 1. Weigh 500kg of corn gluten powder, 100kg of rapeseed meal, 100kg of alcohol meal DDGS, and 400kg of vermicelli protein powder.

[0096] 2. Pickling and enzymatic hydrolysis of corn gluten powder, the specific method is as follows:

[0097] A. Enzymolysis: Pour 500kg of corn gluten powder into a 5000L enzymolysis tank, add water and mix materials according to the ratio of material to water 1:5, then adjust the pH to 4.8 with 0.2mol / L hydrochloric acid, and dissolve the substrate liquid Heat to 52°C, add cellulase and acid protease according to the dosage of 30U / g and 5000U / g, and enzymatically hydrolyze at constant temperature for 60min;

[0098] B. Pickling: adjust the pH of the enzymolyzed substrate liquid to 3.8 with 0.2mol / L hydrochloric acid, stir at 80r / min for 60min at 31°C, centrifuge after the protein aggregates and precipitate, and remove t...

Embodiment 3

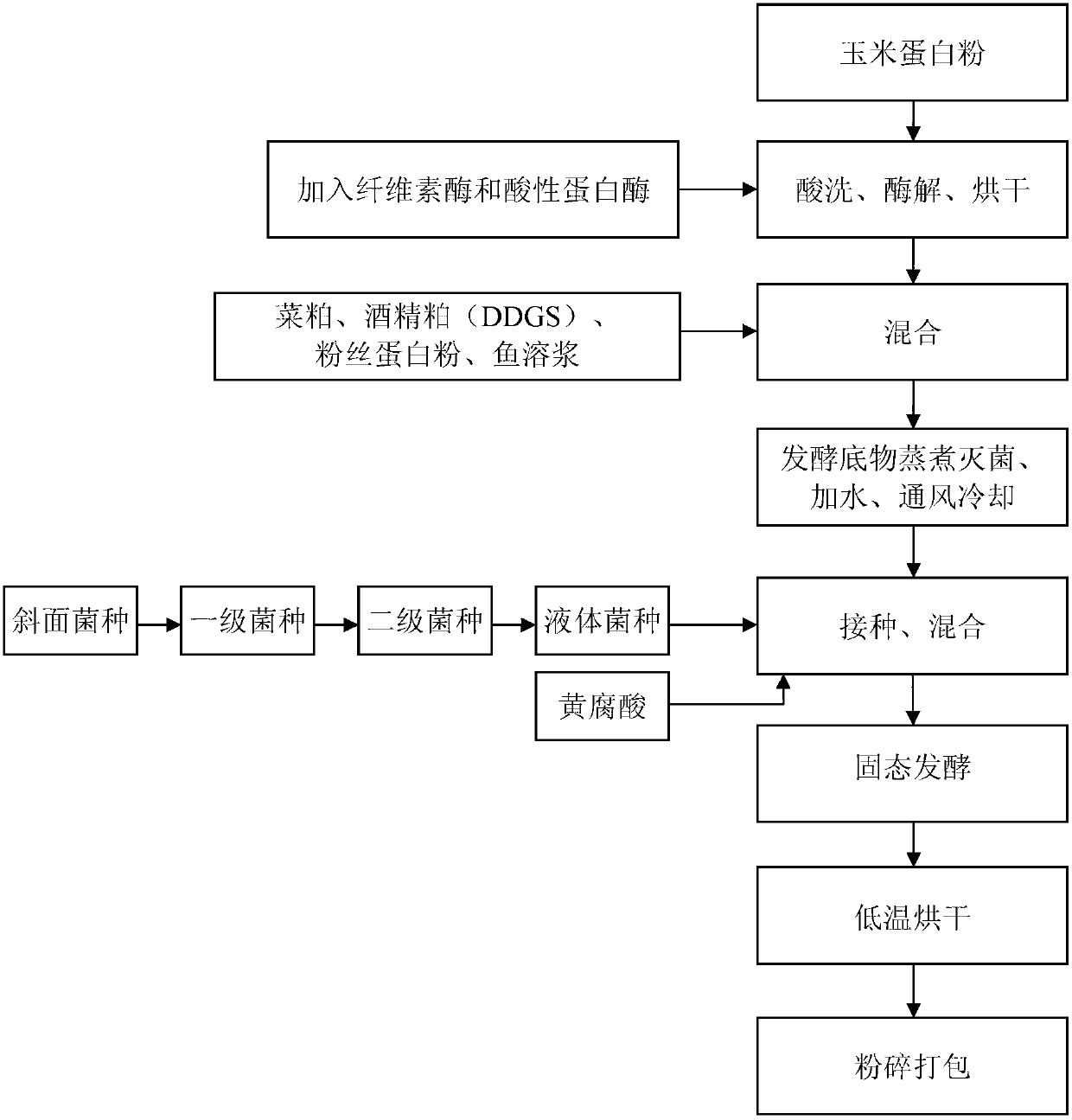

[0109] see figure 2 , prepare the biological fish meal of the present embodiment according to the following method:

[0110] 1. Weigh 600kg of corn gluten powder, 50kg of rapeseed meal, 50kg of alcohol meal DDGS, 400kg of vermicelli protein powder, and 100kg of fish soluble pulp.

[0111] 2. Pickling and enzymatic hydrolysis of corn gluten powder, the specific method is as follows:

[0112] A. Enzymolysis: Pour 600kg of corn gluten powder into a 5000L enzymolysis tank, add water and mix materials according to the ratio of material to water 1:5, then adjust the pH to 4.8 with 0.2mol / L hydrochloric acid, and dissolve the substrate liquid Heat to 52°C, add cellulase and acid protease according to the dosage of 30U / g and 5000U / g, and enzymatically hydrolyze at constant temperature for 60min;

[0113] B. Pickling: adjust the pH of the enzymolyzed substrate liquid to 3.8 with 0.2mol / L hydrochloric acid, stir at 80r / min for 60min at 31°C, centrifuge after the protein aggregates an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com