Method for removing aflatoxin in rice flour

A technology for aflatoxin and rice flour, applied in the application, food preparation, food science and other directions, can solve the problems of the final product flavor and quality damage, difficult to achieve the level of industrialized processing, etc., achieve high detoxification efficiency, reduce space obstacles, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

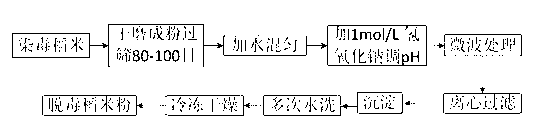

Method used

Image

Examples

Embodiment 1

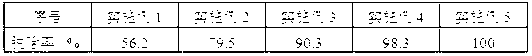

[0023] Pass the above-mentioned moldy rice flour sample through an 80-mesh sieve, take 2g and put it in a 500ml beaker, add 50ml of distilled water at a ratio of solid-liquid ratio (mass ratio) of 1:25, and mix well; add 1 mol of / L sodium hydroxide solution until the pH value is 8.0, and then put it in the MZG1500S microwave experiment instrument (Nanjing Huiyan Microwave System Engineering Co., Ltd.) for microwave heating, the microwave intensity is 300W, and the processing time is 1 min. Stir the above suspension continuously; cool the treated suspension to room temperature (about 24°C), centrifuge at 10°C for 10min at a speed of 8000rpm, recover the centrifuged precipitate, and take the centrifuged supernatant at the same time Filtrate to recover the precipitate; wash the recovered precipitate with distilled water three times, and freeze-dry to obtain aflatoxin-free rice flour.

Embodiment 2

[0025] Pass the above-mentioned moldy rice flour sample through a 90-mesh sieve, take 2g and put it in a 500ml beaker, add 100ml of distilled water at a ratio of 1:50 to the ratio of solid to liquid (mass ratio), and mix well; add 1 mol of / L sodium hydroxide solution until the pH value is 9.0, then place it in a MZG1500S microwave experiment instrument (Nanjing Huiyan Microwave System Engineering Co., Ltd.) for heating, the microwave intensity is 500W, and the processing time is 3 minutes. During the processing Stir the above suspension continuously; cool the treated suspension to room temperature (around 24°C), centrifuge at 10°C for 10 minutes at a speed of 8000rpm, recover the centrifuged precipitate, and filter the centrifuged supernatant , recovering the precipitate; washing the recovered precipitate three times with distilled water, and spray drying to obtain aflatoxin-free rice flour.

Embodiment 3

[0027] Pass the above-mentioned moldy rice flour sample through a 100-mesh sieve, take 2g and place it in a 500ml beaker, add 150ml of distilled water at a ratio of 1:75 to the ratio of solid to liquid (mass ratio), and mix well; add 1 mol of / L sodium hydroxide solution until the pH value is 10.0, then place it in a MZG1500S microwave experiment instrument (Nanjing Huiyan Microwave System Engineering Co., Ltd.) for heating, the microwave intensity is 600W, and the processing time is 5 minutes. During the processing Stir the above suspension continuously; cool the treated suspension to room temperature (around 24°C), centrifuge at 10°C for 10 minutes at a speed of 8000rpm, recover the centrifuged precipitate, and filter the centrifuged supernatant , recovering the precipitate; washing the recovered precipitate with distilled water for 4 times, and freeze-drying to obtain aflatoxin-free rice flour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com