Instant yolk powder and preparation method thereof

A technology of egg yolk powder and instant dissolving, which is applied in the production of egg yolk powder and the field of preparing instant egg yolk powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

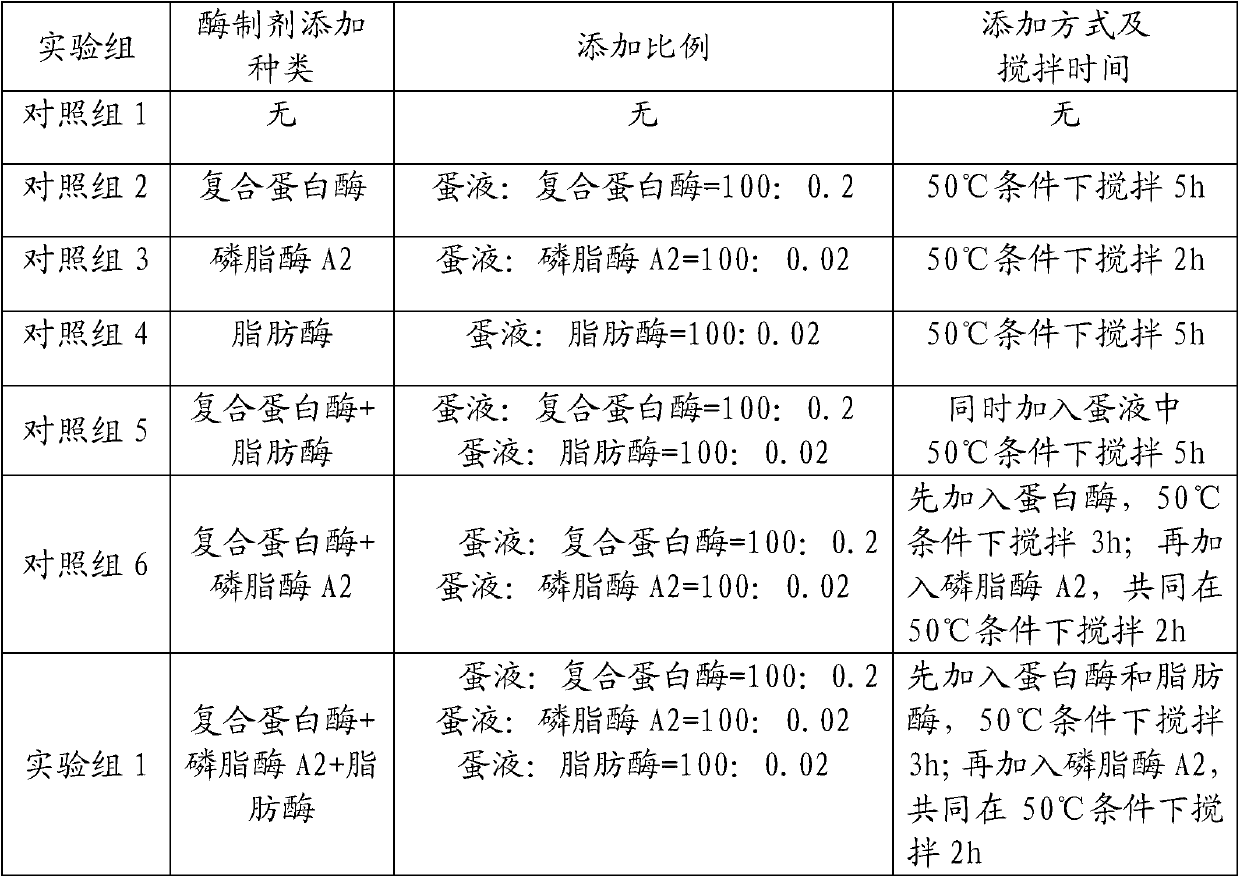

Method used

Image

Examples

Embodiment 1

[0102] Take 2.5kg of beaten egg yolk liquid, send it to a homogenizer for homogenization treatment, adjust the homogenization pressure to 20MPa; weigh 5.0g of compound protease and 0.5g of lipase, mix with water, stir evenly without agglomeration and add Put it into the egg yolk liquid, heat and stir it in a 50°C water bath for 3 hours; weigh another 10.5ml of phospholipase A, and then heat it and stir it in a 50°C water bath for 2 hours; pasteurize the egg yolk liquid after stirring and heat preservation, and the sterilization temperature is 60°C , the pasteurized temperature is 59°C, and the sterilization time is 210s; the pasteurized egg yolk liquid is spray-dried, the air inlet temperature of the centrifugal spray is 160°C, and the air outlet temperature is 78°C to obtain 1060g of egg yolk powder; After boiling and granulating, 950 g of egg yolk powder was obtained.

[0103] The obtained egg yolk powder can be quickly dispersed in water, the upper layer has no lumps, and f...

Embodiment 2

[0105] Take 2.5kg of beaten egg yolk, use a colloid mill for preliminary emulsification, and send it to a homogenizer for homogenization treatment, adjusting the homogenization pressure to 10MPa; weigh 3.0g of neutral protease and 0.3g of lipase, and mix with water , stirred evenly without agglomeration, added to the egg yolk liquid, and kept stirring in a 40°C water bath for 4 hours; another 20.3ml of phospholipase A was weighed and stirred at 40°C for 3 hours; the stirred egg yolk liquid was spray-dried, and the centrifugal spraying The wind temperature is 170°C, and the outlet air temperature is 80°C to obtain egg yolk powder.

Embodiment 3

[0107] Take 3.0kg of beaten egg yolk, emulsify with a colloid mill at a low speed, then homogenize with a homogenizer, and adjust the homogenization pressure to 15MPa; weigh 7.5g of flavor protease and 0.9g of lipase, and mix with water , stir evenly without agglomeration, add it to the egg yolk liquid, keep stirring in a water bath at 60°C for 1 hour; add 0.7ml of phospholipase C into the egg yolk liquid, stir at 60°C for 3 hours; pasteurize the egg yolk liquid after heat preservation and stirring Sterilization, the sterilization temperature is 65°C, the pasteurization temperature is 64°C, and the sterilization time is 120s; the pasteurized egg yolk liquid is spray-dried, the inlet air temperature of the centrifugal spray is 180°C, and the outlet air temperature is 75°C to obtain the egg yolk pink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com