Method for preparing glycerophosphorylcholine (GPC) by phospholipase-catalyzed hydrolysis

A technology of glycerophosphocholine and phospholipase, which is applied in the directions of edible phospholipid composition, food science, protein food ingredients, etc., can solve the problems of low conversion rate, insufficient product purity and high cost, and achieves safe industrial production and simple purification process. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

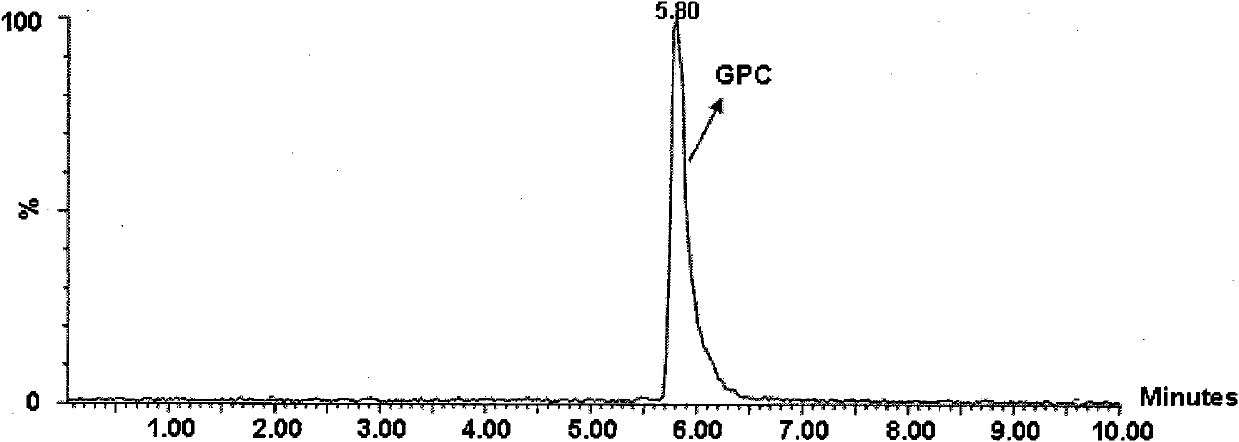

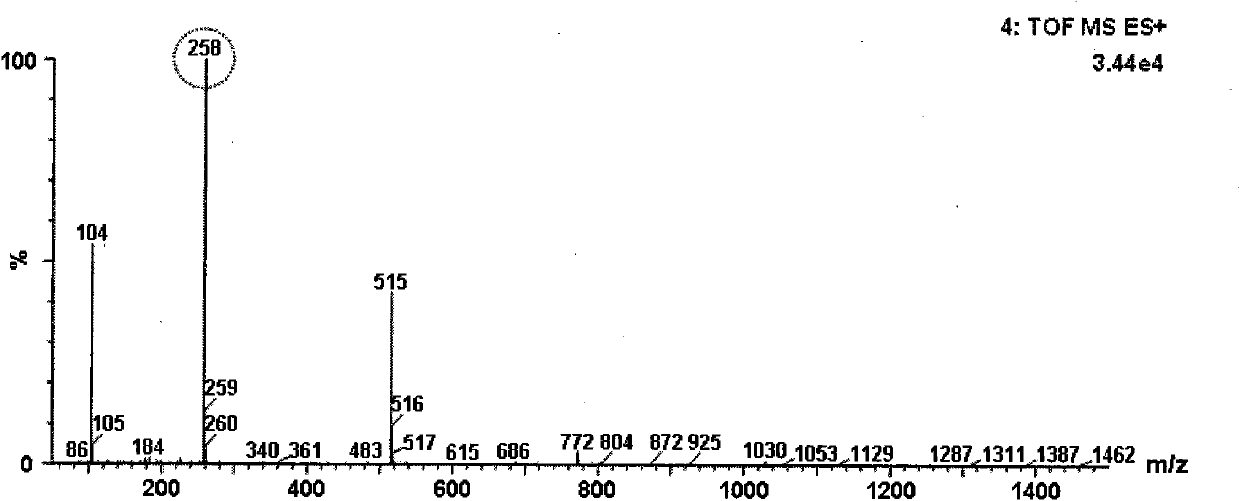

Image

Examples

Embodiment 1

[0023] The raw material used is food-grade powdered phospholipid (wherein the PC content is about 24%).

[0024] Preparation of alcohol-soluble phospholipids: Add 80 mL of 95% ethanol solution to 20 g of powdered phospholipids, mechanically stir at 300 r / min for 120 min in water at 55 ° C, and filter with suction to obtain a phospholipid ethanol solution; the filter cake is repeatedly extracted three times under the same conditions, and the obtained The ethanol solutions of phospholipids were combined and rotary evaporated at 40° C. under vacuum to obtain 7.2 g of alcohol-soluble phospholipid solids with a PC content of 60.2%, a PC recovery rate of 90.6%, and ethanol recovery.

[0025] The resulting alcohol-soluble phospholipid: golden yellow, easy to absorb moisture, oxidize, easily disperse in water and form a stable emulsion, insoluble in acetone, soluble in organic solvents such as ethanol, ether and hexane.

Embodiment 2

[0027] The prolamin phospholipid raw material used is the product of Example 1 (PC content is 60.2%).

[0028] Preparation of high-purity PC: Add 80 mL of 95% ethanol solution to 20 g of alcohol-soluble phospholipids, let stand at -20°C for 80 minutes, and filter with suction to obtain a phospholipid ethanol solution. The filter cake is crystallized three times under the same conditions, and the obtained phospholipids are The ethanol and alcohol solutions were combined and rotary evaporated at 40° C. under vacuum to obtain 14.25 g of alcohol-soluble phospholipid solids with a PC content of 81.5%, a PC recovery rate of 95.1%, and ethanol recovery.

[0029] The resulting alcohol-soluble phospholipid: golden yellow, easy to absorb moisture, oxidize, easily disperse in water and form a stable emulsion, insoluble in acetone, soluble in organic solvents such as ethanol, ether and hexane.

Embodiment 3

[0031] The raw materials used are powdered phospholipids, alcohol-soluble phospholipids and high-purity PC.

[0032] Preparation of enzymatic hydrolysis reaction solution: add 150mL deionized water to 5g phospholipids (powder phospholipids, alcohol-soluble phospholipids, high-purity PC), heat in a water bath, mechanically stir at 300r / min for 30min, add 0.5mL phospholipase, and then add 0.3 g of metal salt, reacted for 3 hours to obtain an enzymatic hydrolysis reaction liquid, and filtered to obtain a clear enzymatic hydrolysis reaction liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com