Preparation method, structural feature and application of carrying type nanometer electrocatalyst

An electrocatalyst, supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high reaction temperature, unsuitable for large-scale synthesis, stable It is difficult to remove the agent and other problems, so as to achieve the effect of simple operation and a wide range of carrier selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Dissolve 145.78mg of cetyltrimethylammonium bromide in 10mL of chloroform, first add 58.52mg of commercial carbon black (Vulcan XC-72R), sonicate for 30 minutes, and then add 10mL of 20mmol / L K 2 PtCl 4 Aqueous solution, stirred for 2 hours at 25°C, let stand, separate to remove the upper aqueous phase, then add 90mL of deionized water, stir at high speed (greater than 400rpm), add 10mL of 300mmol / L NaBH 4 Aqueous solution, react for 5 minutes, evaporate and remove the chloroform in the system; use 2 liters of deionized water for multiple suction filtration and washing; vacuum drying for more than 6 hours to obtain a supported nano electrocatalyst with a theoretical loading of 40%.

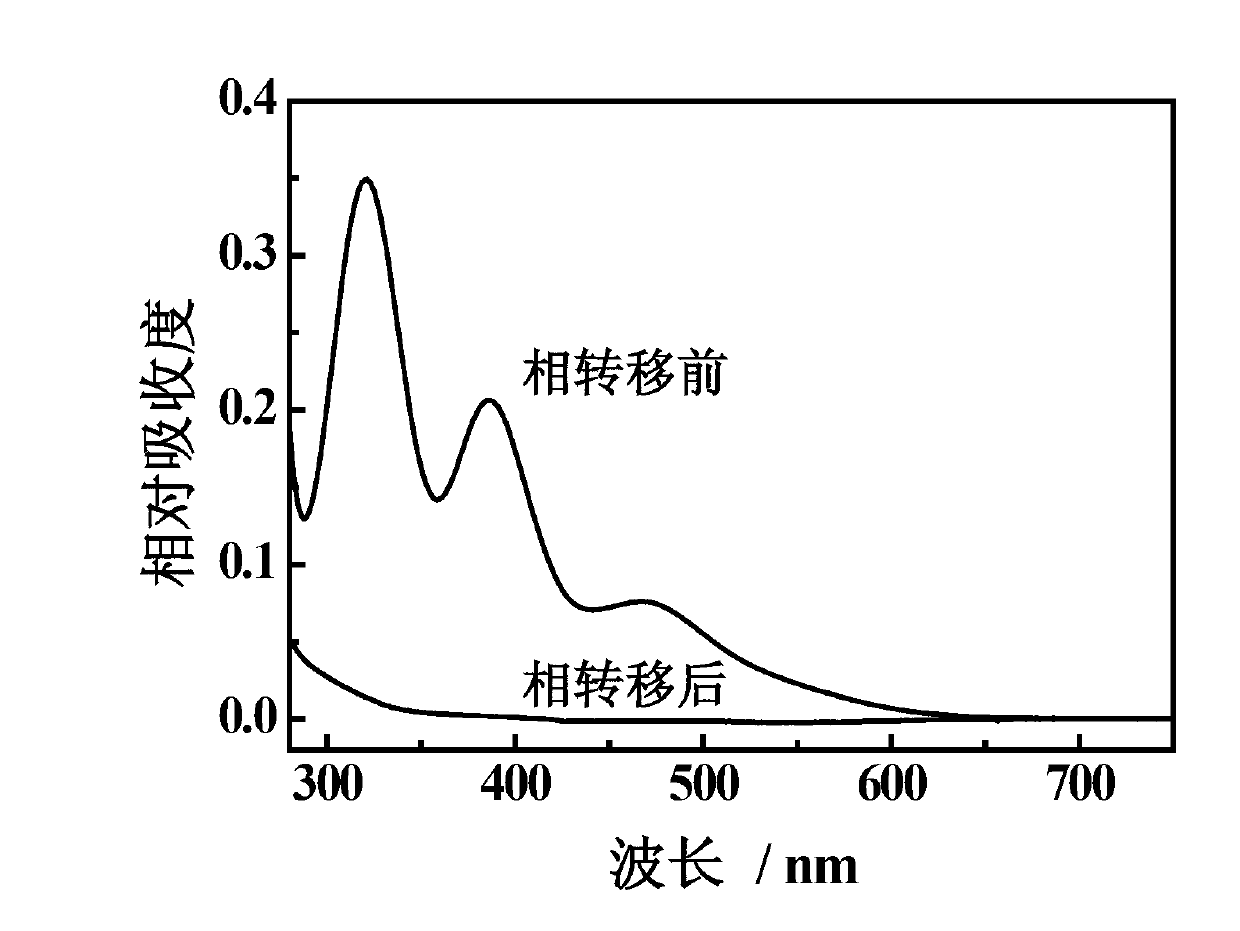

[0054] Such as figure 1 , UV-Vis spectra showed that the characteristic absorption peak of platinum salt disappeared after phase transfer, indicating that the phase transfer process was sufficient.

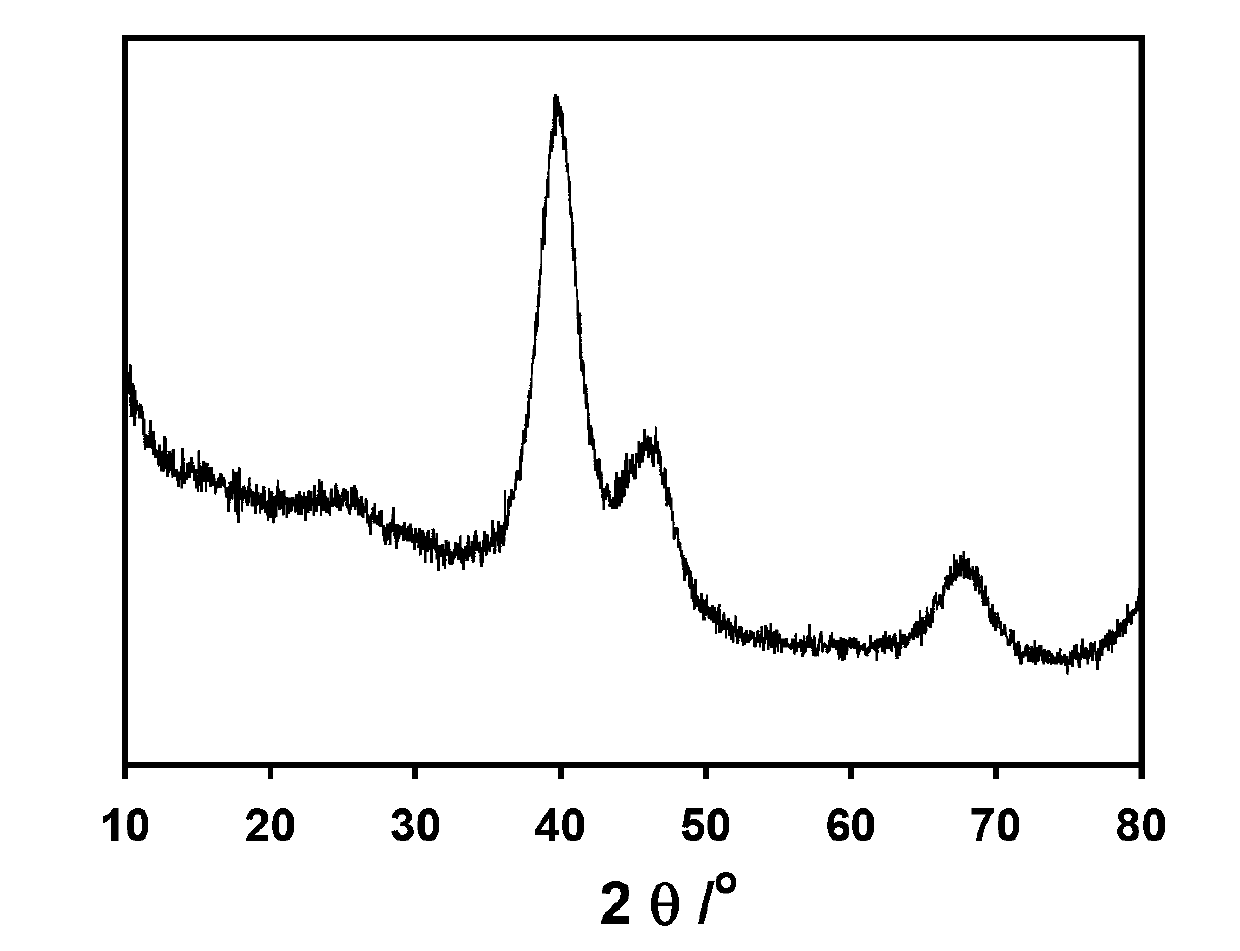

[0055] Such as figure 2 , XRD spectra showed that the resulting product was composed of Pt parti...

Embodiment 2

[0062] Dissolve 145.78mg of cetyltrimethylammonium bromide in 10mL of chloroform, first add 58.52mg of commercial carbon black (Vulcan XC-72R), sonicate for 30 minutes, and then add 0.7894mL of 20mmol / L K 2 PtCl 4 Aqueous solution, stirred for 2 hours at 25°C, stand still, separate and remove the upper aqueous phase, then add 90 mL of deionized water, stir at high speed (greater than 400 rpm), and add 0.8 mL of 300 mmol / L NaBH 4 Aqueous solution, react for 5 minutes, evaporate and remove the chloroform in the system; use 2 liters of deionized water for multiple suction filtration and washing; vacuum drying for more than 6 hours to obtain a supported nano electrocatalyst with a theoretical loading of 5%.

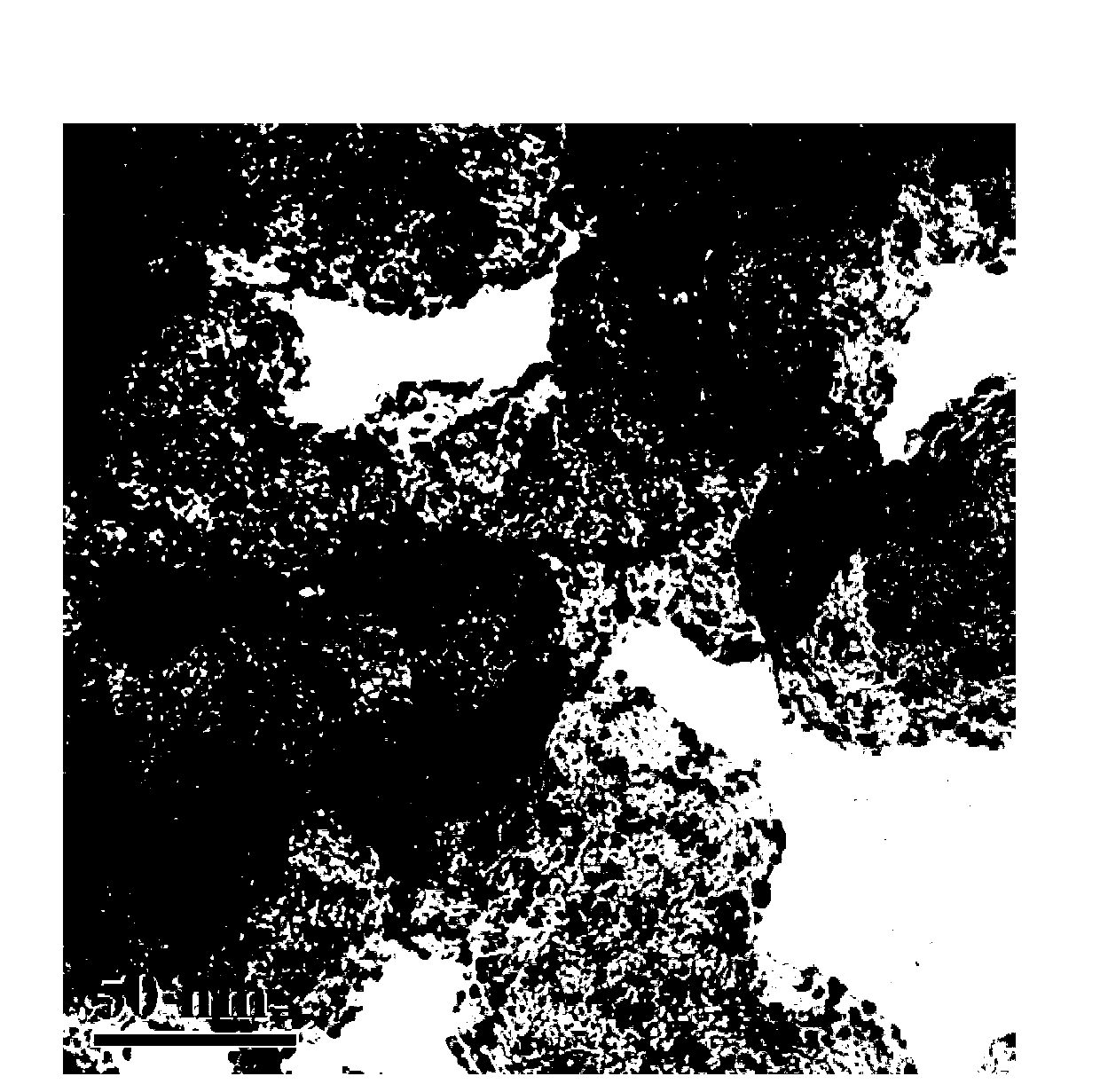

[0063] Such as Figure 8 The catalyst prepared in Example 2 has a nearly spherical morphology, uniform particle size, and uniform distribution on the surface of the carrier.

Embodiment 3

[0065] Dissolve 145.78mg of cetyltrimethylammonium bromide in 10mL of chloroform, first add 13.01mg of commercial carbon black (Ketjen EC-300), sonicate for 30 minutes, and then add 10mL of 20mmol / L K 2 PtCl 4 Aqueous solution, stirred for 2 hours at 25°C, let stand, separate to remove the upper aqueous phase, then add 90mL of deionized water, stir at high speed (greater than 400rpm), add 10mL of 300mmol / L NaBH 4 Aqueous solution, react for 5 minutes, evaporate and remove the chloroform in the system; use 2 liters of deionized water for multiple suction filtration and washing; vacuum drying for more than 6 hours to obtain a supported nano electrocatalyst.

[0066] Such as Picture 9 The catalyst prepared in Example 3 has a single morphology and uniform size.

[0067] Such as Picture 10 The particle size distribution shows that the average particle size is 3.07±0.47nm, and the particle size distribution is 15.33%.

[0068] Such as Picture 11 , Thermogravimetric analysis determined th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com