Cleaning and sterilizing method of circulating water system, and bactericide

A technology of circulating water system and bactericide, which is applied in the direction of cleaning methods and appliances, biocides, chemical instruments and methods, etc., can solve the problems that cannot be used in a large area, cannot completely kill Legionella bacteria, organisms, etc., to solve corrosion problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

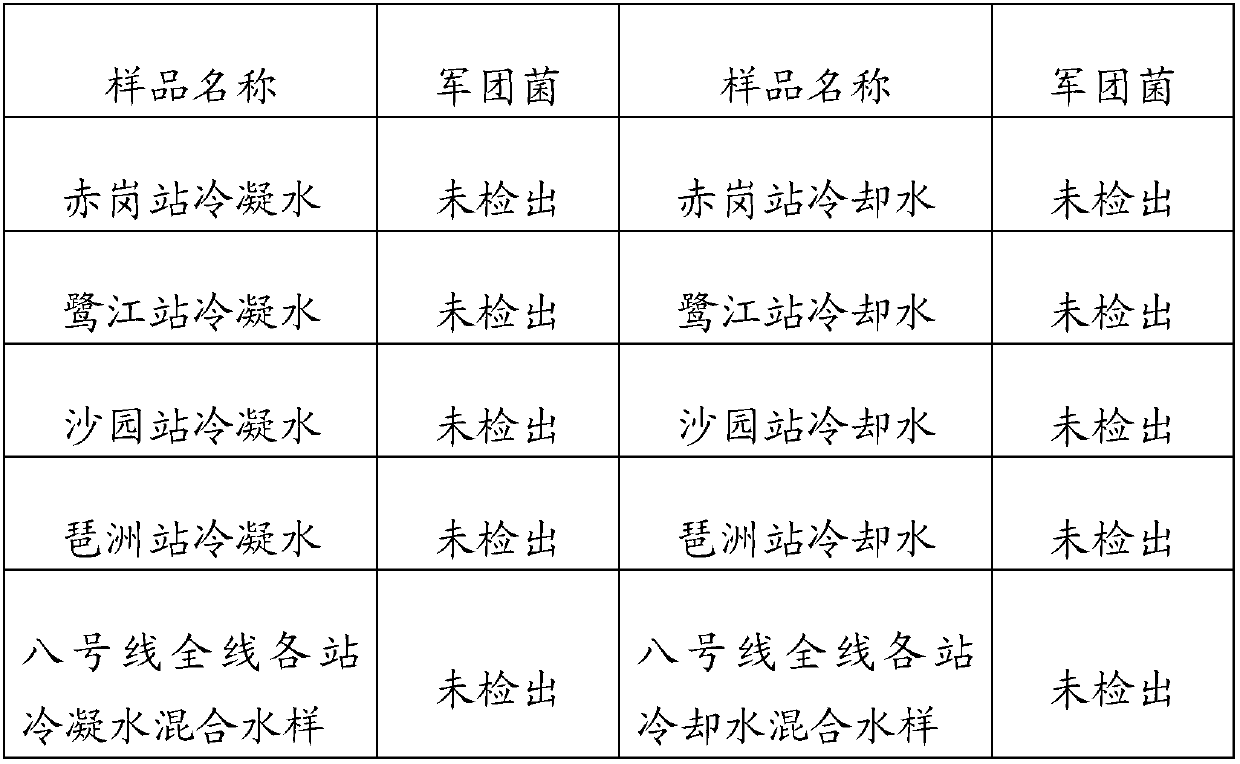

[0030] The following methods are used to clean and sterilize the central air-conditioning circulating water system of each station of Guangzhou Metro Line 8, and the method includes the following steps:

[0031] 1. Slime peeling

[0032] Use a high-pressure jet device to clean the cooling tower, heat sink and surrounding environment of the circulating water system, remove the dust, sludge and scale on the cooling tower, provide a good external environment, and reduce the influencing factors; add biological slime to strip When the chemical agent is used, the cooling pump is turned on to circulate for 16-24 hours. During this period, the water samples are analyzed for the chemical content in different periods. When the chemical content decreases, the biological slime stripping agent is added to maintain the content of the biological slime stripping agent in the circulating water system. 200ppm to effectively strip biological slime in the circulating water system. After the biol...

Embodiment 2

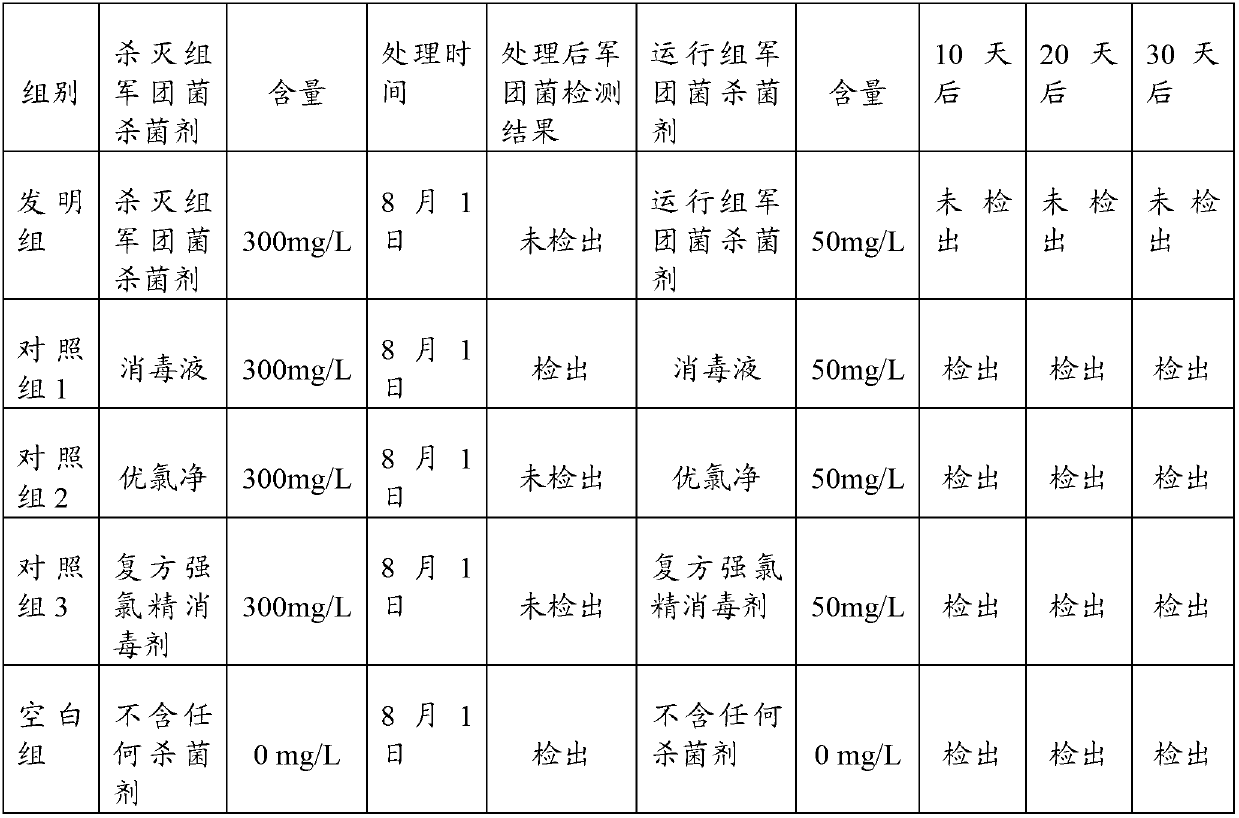

[0048] The circulating water system of the central air conditioner is treated with the same method as in Example 1, and the treatment time is the peak season of the central air conditioner: in August, the central air conditioner has a circulating water system of the same size and the same concentration multiple. The difference from Example 1 is that the Legionella bactericide of the killing group and the Legionella bactericide of the operating group are different.

[0049] The killing group Legionella bactericide of the invention group includes the following components by weight: 30 parts of glutaraldehyde, 30 parts of sodium 3-chloroisocyanurate, 25 parts of HEDP, and 15 parts of zinc sulfate; it is prepared by the following method : Put glutaraldehyde, sodium 3-chloroisocyanurate, HEDP and zinc sulfate into the reaction kettle, control the temperature at 10°C~20°C, stir at high speed for 2~3 hours, and then kill the Legionella bacteria agent; the operating group Legionella b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com