Optical component surface cleaning method based on ion beam polishing

A technology for optical components and surface cleaning, which is applied in the field of ultra-precision processing of optical components, can solve the problems that the KDP crystal surface cleaning method needs to be improved, and achieve the effects of low equipment requirements, reduced roughness value, and guaranteed processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

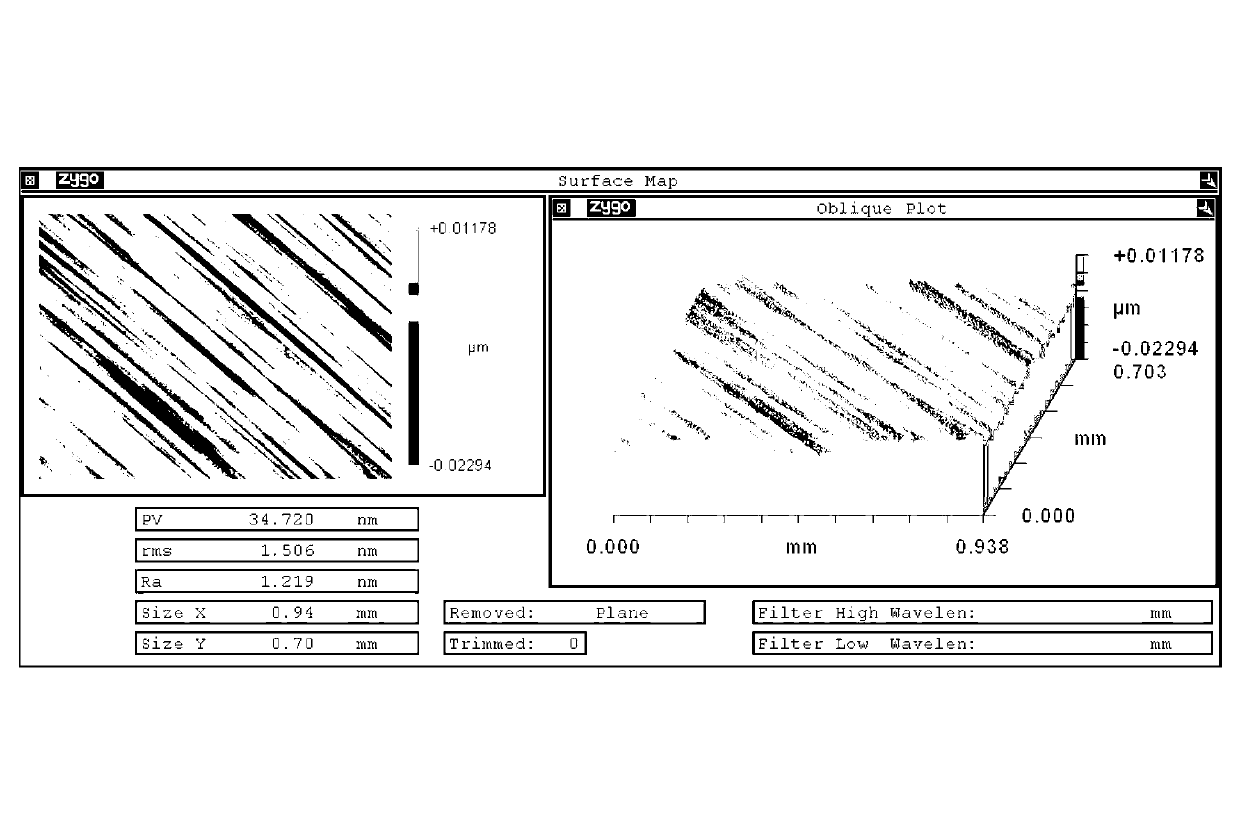

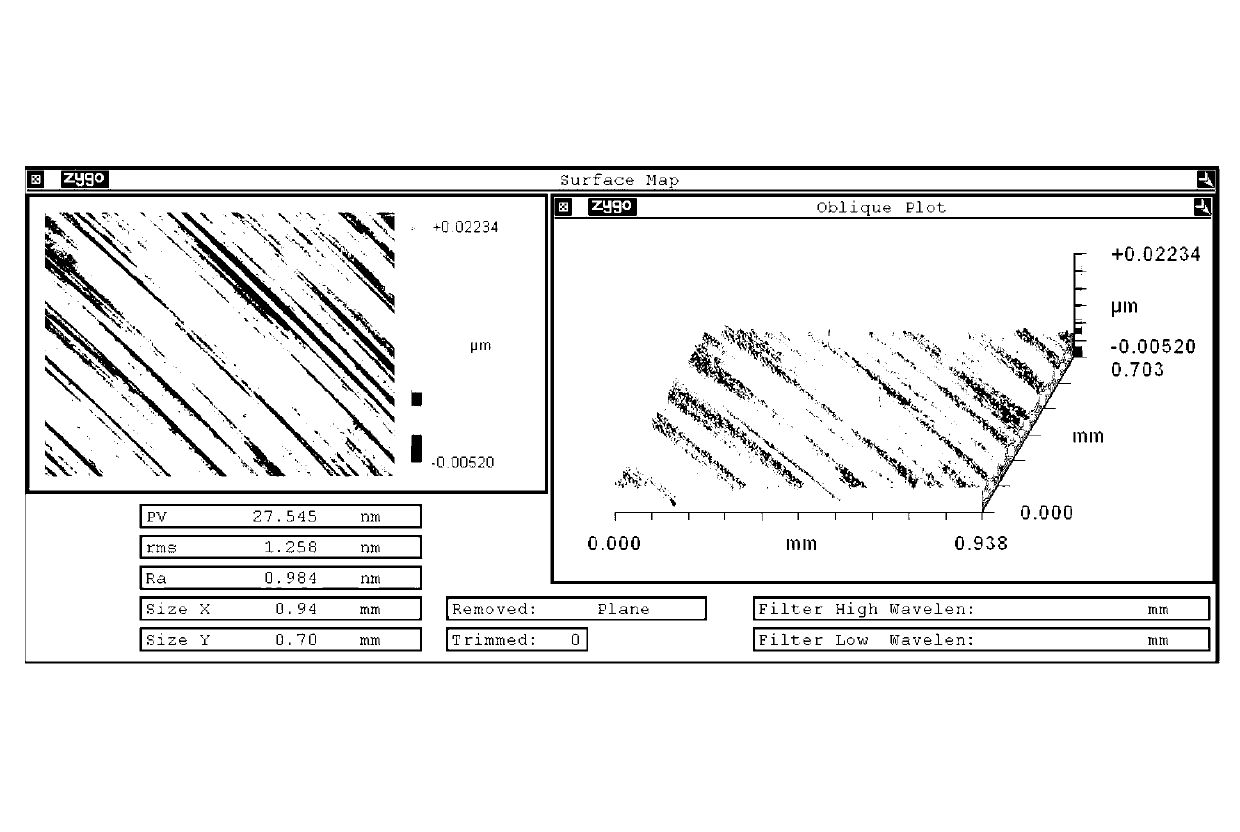

[0023] A method for cleaning the surface of an optical element based on ion beam polishing of the present invention, comprising the following steps: firstly, using single-point diamond turning, the pair of dimensions are 50 × 50 × 10 mm 3 The class II KDP crystal sample 1 and sample 2 were turned, and the main process parameters of single-point diamond turning were controlled as follows: spindle speed 500 r / min, feed rate 2 μm / r, cutting depth 1 μm; The sample 2 of single-point diamond turning is used as the processing object (sample 1 is used as the control), and the surface of the processing object is processed by the ion beam polishing method based on the principle of low-energy ion sputtering. The surface of the component is uniformly scanned, and the main process parameters of ion beam polishing are controlled as follows: incident ion energy 400 eV, ion beam current 30 mA, ion beam incident angle 45° (the image during processing is as follows figure 1 shown); the removal ...

Embodiment 2

[0026] A method for cleaning the surface of an optical element based on ion beam polishing of the present invention, comprising the following steps:

[0027] In order to facilitate the analysis and comparison of the samples by the secondary ion mass spectrometer, three blocks with a size of 8×8×2 mm were selected in this embodiment. 3Type II KDP crystals; among them, sample 3 was subjected to single-point diamond turning; sample 4 was subjected to magnetorheological polishing after single-point diamond turning; sample 5 was subjected to ion beam polishing after single-point diamond turning and magnetorheological polishing (Sample 3 and Sample 4 are used as controls);

[0028] Among them, the process parameters of the single-point diamond turning of each sample are controlled as follows: the spindle speed is 500 r / min, the feed rate is 2 μm / r, and the cutting depth is 1 μm;

[0029] The main process parameters used in the magnetorheological polishing of sample 4 and sample 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com