Preparation method of hollow micron-cage structure MoO3 nanometer material

A nano-material, hollow technology, applied in the field of preparation of hollow micro-cage structure MoO3 nano-materials, to achieve the effect of small crystal size, simple process and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 50ml of deionized water to 50ml of absolute ethanol, stir well and add 1.24g of (NH 4 ) 6 Mo 7 o 24 4H 2 O, after stirring for 20 minutes with a magnetic stirrer, 0.02mol / L of (NH 4 ) 6 Mo 7 o 24 solution. Then add 0.2 g K to the solution 3 PO 4 The solid was stirred for 50 minutes with a magnetic stirrer;

[0028] (2) Add 2.2mol / L of HNO dropwise to the mixed solution described in step (1) 3 solution, adjust the pH to 1.5, then stir with a magnetic stirrer for 30 minutes;

[0029] (3) Transfer the solution obtained in step (2) to a hydrothermal kettle, heat it at 160°C for 20 hours, and then cool it with the furnace. Then the obtained solution was centrifuged, and the obtained precipitate was washed with deionized water and absolute ethanol for 6 times respectively, and the washed precipitate was dried at 60°C for 20 hours, and then ground into powder to obtain a hollow micron cage Structure MoO 3 nanomaterials.

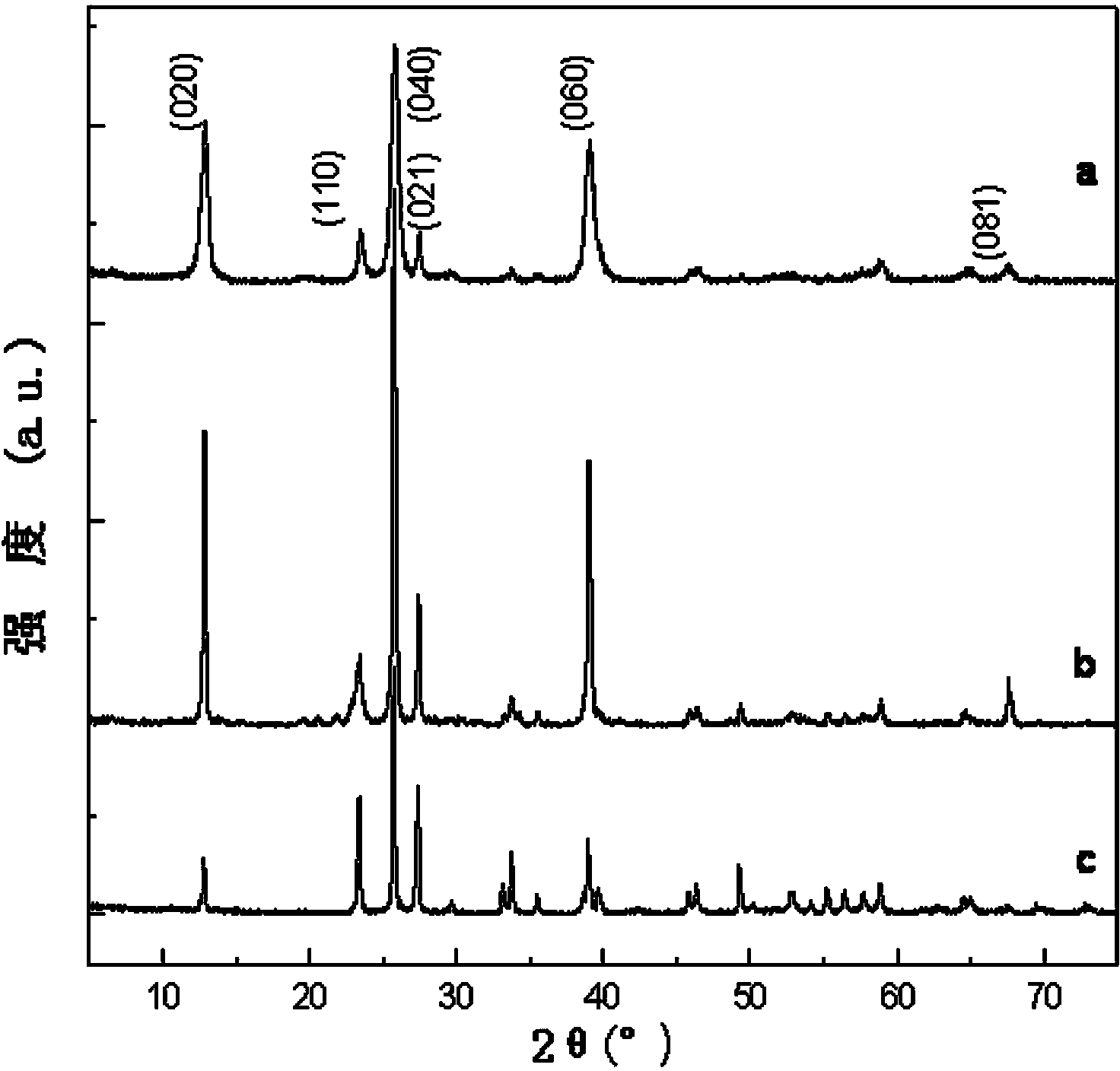

[0030] figure 1 a is the X-ray ...

Embodiment 2

[0033] (1) Add 50ml of deionized water to 50ml of absolute ethanol, stir well and add 1.24g of (NH 4 ) 6 Mo 7 o 24 4H 2 O, after stirring for 20 minutes with a magnetic stirrer, 0.02mol / L of (NH 4 ) 6 Mo 7 o 24 solution. Then add 0.4 g K to the solution 3 PO 4 The solid was stirred for 50 minutes with a magnetic stirrer;

[0034] (2) Add 2.2mol / L of HNO dropwise to the mixed solution described in step (1) 3 solution, adjust the pH to 1.5, then stir with a magnetic stirrer for 30 minutes;

[0035] (3) Transfer the solution obtained in step (2) to a hydrothermal kettle, heat it at 180°C for 20 hours, and then cool it with the furnace. Then the obtained solution was centrifuged, and the obtained precipitate was washed with deionized water and absolute ethanol for 6 times, and the washed precipitate was dried at 60°C for 20 hours, and then ground into powder to obtain the hollow micron cage Structure MoO 3 nanomaterials.

[0036] figure 1 b is the X-ray diffraction p...

Embodiment 3

[0039] (1) Add 50ml of deionized water to 50ml of absolute ethanol, stir well and add 1.24g of (NH 4 ) 6 Mo 7 o 24 4H 2 O, after stirring for 20 minutes with a magnetic stirrer, 0.02mol / L of (NH 4 ) 6 Mo 7 o 24 solution. Then add 0.4g K to the AHM solution 3 PO 4 The solid was stirred for 50 minutes with a magnetic stirrer;

[0040] (2) Add 2.2mol / L of HNO dropwise to the mixed solution described in step (1) 3 solution, adjust the pH of the solution to 1.5, and stir with a magnetic stirrer for 30 minutes;

[0041] (3) Transfer the solution obtained in step (2) to a hydrothermal kettle, heat it at 180°C for 24 hours, and then cool it with the furnace. Then the obtained solution was centrifuged, and the obtained precipitate was washed with deionized water and absolute ethanol for 6 times respectively, and the washed precipitate was dried at 60°C for 20 hours, and then ground into powder to obtain the hollow micron cage Structure MoO 3 nanomaterials.

[0042] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com