High-temperature-resistant high-silica fiber glass

A high-silica fiber, high-temperature-resistant technology, applied in the field of high-silica fiber glass binary component formulation, can solve the problems of high manufacturing cost, large material loss, environmental pollution, etc., to reduce production cost, stabilize molding process, The effect of improving the melting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0008] A high silica fiber glass binary component formulation: SiO 2 : 76.0%; Na 2 O: 21.0%; Al 2 o 3 : 3%.

[0009] The above components are prepared according to the following process to prepare binary component high silica fiber glass. The specific process is as follows:

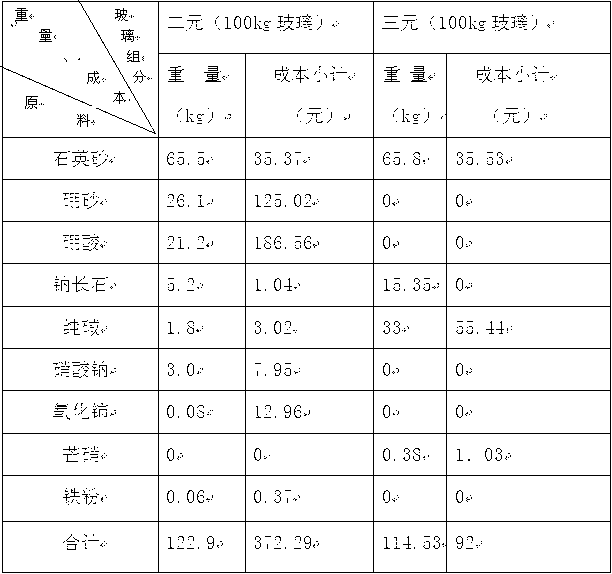

[0010] Raw material preparation: taking 100g of glass as an example, 65.8g of quartz sand, 33.0g of soda ash, 15.3g of albite feldspar, and 0.38g of sodium sulfate.

[0011] After the above raw materials are mixed, they are melted and drawn in a platinum crucible. After the wire drawing is finished, the conventional winding and weaving processes are adopted. I won't repeat it here.

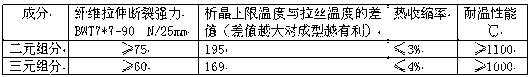

[0012] The relevant performance data of the high silica glass fiber (such as high silica mesh BWT7*7-90) made from the above components and the high silica glass fiber made from the three-component component are as follows:

[0013] .

[0014] The raw material cost of binary high-silica and ternary high-silica glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com