Synthetic method of bridged metallocene dinuclear catalyst

A synthesis method and metallocene technology, applied in the field of polyolefins, can solve the problems of cumbersome post-processing, low total yield, and many steps, and achieve the effects of avoiding the use of expensive reagents, short synthesis routes, and high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

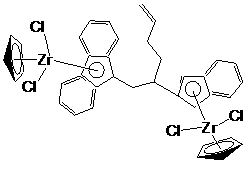

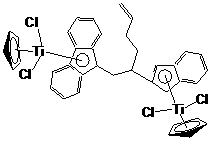

[0029] The preparation method of bridged metallocene dinuclear catalyst is as follows:

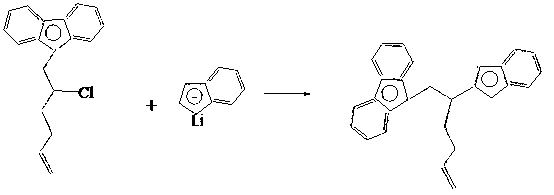

[0030] 1) Synthesis of fluorenyl ligands

[0031] Dissolve 5-chloro-6-bromo-1-hexene in an organic solvent, lower the temperature to -30-0°C, slowly add the fluorene lithium solution dropwise, the dropping time is 1.5-2.5 hours, and continue the reaction for 10-12 hours after the dropping ;

[0032] The molar ratio of 5-chloro-6-bromo-1-hexene to lithium fluorene is: 5-chloro-6-bromo-1-hexene:lithium fluorene=1~1.1:1;

[0033] The organic solvent is selected from anhydrous diethyl ether or petroleum ether.

[0034] The synthesis method is shown in the following formula:

[0035] .

[0036] The choice of solvent is very important. Using anhydrous ether or petroleum ether as a solvent can effectively control the degree of reaction, and can control the reaction of Br in 5-chloro-6-bromo-1-hexene, while Cl does not react. . When using dichloromethane, toluene or tetrahydrofuran and oth...

Embodiment 1

[0058] 1) Synthesis of fluorenyl ligands

[0059] Dissolve 5-chloro-6-bromo-1-hexene in petroleum ether, lower the temperature to -30°C, slowly add fluorene lithium solution dropwise for 2 hours, and continue the reaction for 10 hours after the addition; 5-chloro-6 The molar ratio of bromo-1-hexene to lithium fluorene is: 5-chloro-6-bromo-1-hexene:lithium fluorene=1:1.

[0060] 2) Synthesis of bridged indenylfluorenyl ligands

[0061] Step 1) adding solvent tetrahydrofuran to the obtained fluorenyl ligand, and then reacting with indene lithium to obtain a bridged indenyl fluorenyl ligand. The molar ratio of fluorenyl ligand to indene lithium is 1:1; the reaction temperature is -20°C; the reaction time is 18 hours.

[0062] 3) Synthesis of Ligand Lithium Salt

[0063] Dissolve the ligand obtained in step 2) in n-hexane, add n-butyllithium dropwise, the dropping temperature is -20°C, the molar ratio of ligand to n-butyllithium is 1:2.2, after the addition is completed, the na...

Embodiment 2

[0070] 1) Synthesis of fluorenyl ligands

[0071] Dissolve 5-chloro-6-bromo-1-hexene in petroleum ether, lower the temperature to -20°C, slowly add the fluorene lithium solution dropwise, the dropwise addition time is 2.5 hours, and continue the reaction for 8 hours after the addition; 5-chloro-6 The molar ratio of bromo-1-hexene to lithium fluorene is: 5-chloro-6-bromo-1-hexene:lithium fluorene=1.1:1.

[0072] 2) Synthesis of bridged indenylfluorenyl ligands

[0073] Step 1) adding solvent tetrahydrofuran to the obtained fluorenyl ligand, and then reacting with indene lithium to obtain a bridged indenyl fluorenyl ligand. The molar ratio of fluorenyl ligand to indene lithium is 1:1; the reaction temperature is -10°C; the reaction time is 14 hours.

[0074] 3) Synthesis of Ligand Lithium Salt

[0075] Dissolve the ligand obtained in step 2) in n-hexane, add n-butyllithium dropwise, the dropping temperature is 0°C, the molar ratio of ligand to n-butyllithium is 1:2.5, after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com