Waterborne epoxy antirust paint and preparation method

A water-based epoxy and anti-rust paint technology, applied in the field of anti-rust paint, can solve the problems of poor low-temperature curing, endangering human health, polluting the environment, etc., and achieve the effects of excellent water resistance, excellent anti-rust, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] A kind of water-based epoxy antirust paint, described antirust paint mainly is made up of A component and B component by mass ratio 2.5:1:

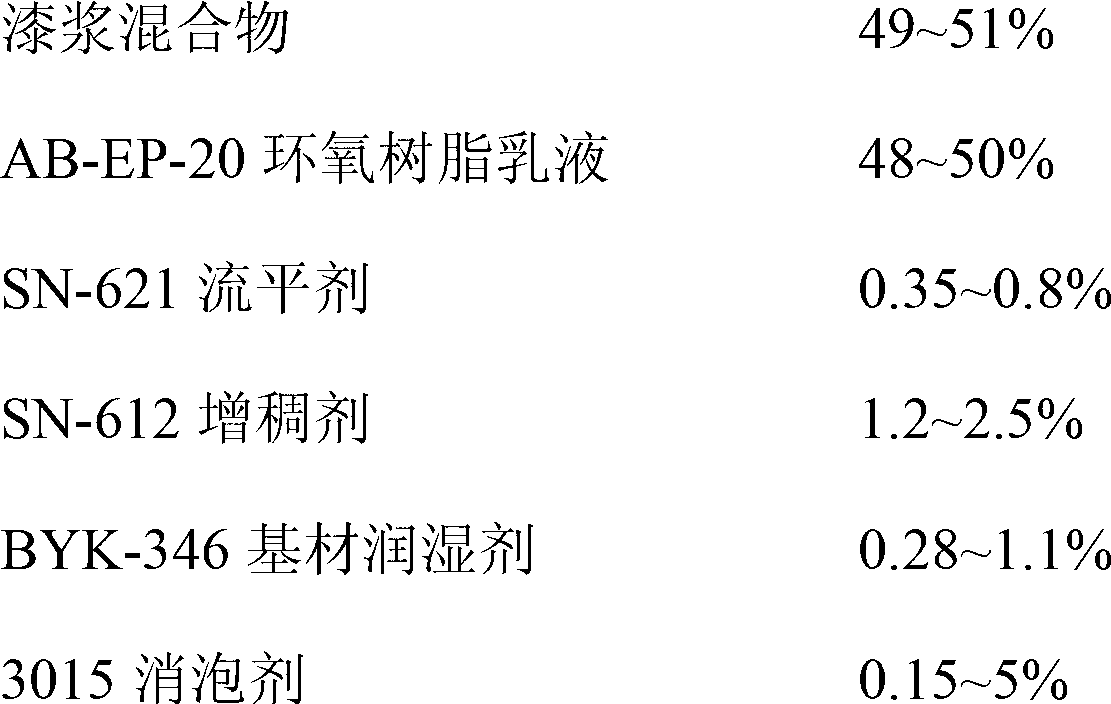

[0084] 1) The component A includes the following components by mass percentage:

[0085]

[0086] The sum of the above components is 100%;

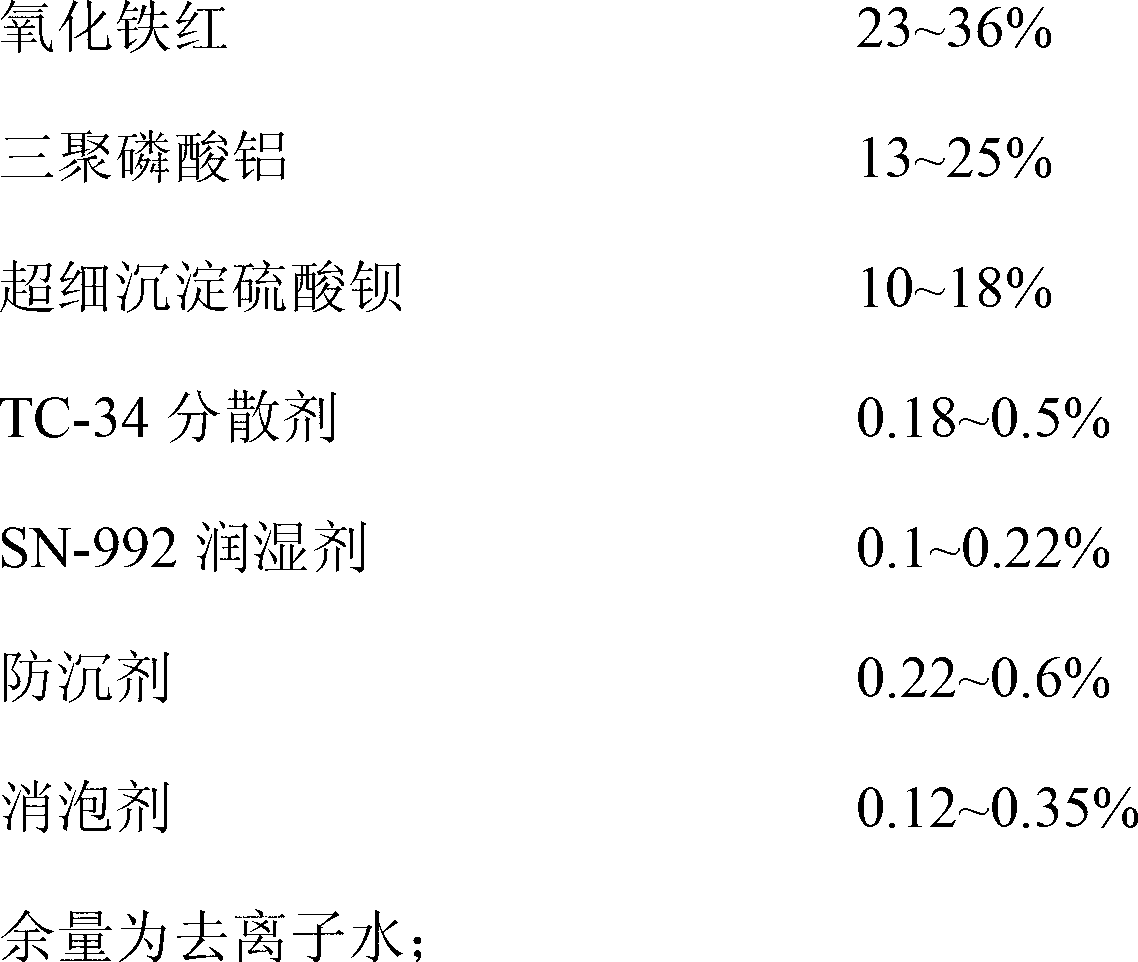

[0087] Wherein, the millbase mixture comprises the following components by mass percentage:

[0088]

[0089] 2) The B component is water-based epoxy curing agent AB-HGF.

[0090] The preparation method of described waterborne epoxy antirust paint, comprises the following steps:

[0091] 1) First prepare the millbase mixture according to the formula quantity, and the millbase mixture is obtained by pre-dispersing each component and then grinding;

[0092] 2) Mix, stir, and filter the millbase mixture, epoxy resin emulsion, and additives obtained in step 1) according to the formula to obtain the component A;

[0093] 3) Pack the components A and B obtained in step 2) according to the ...

Embodiment 2

[0095] A kind of water-based epoxy antirust paint, described antirust paint mainly is made up of A component and B component by mass ratio 7.5:1:

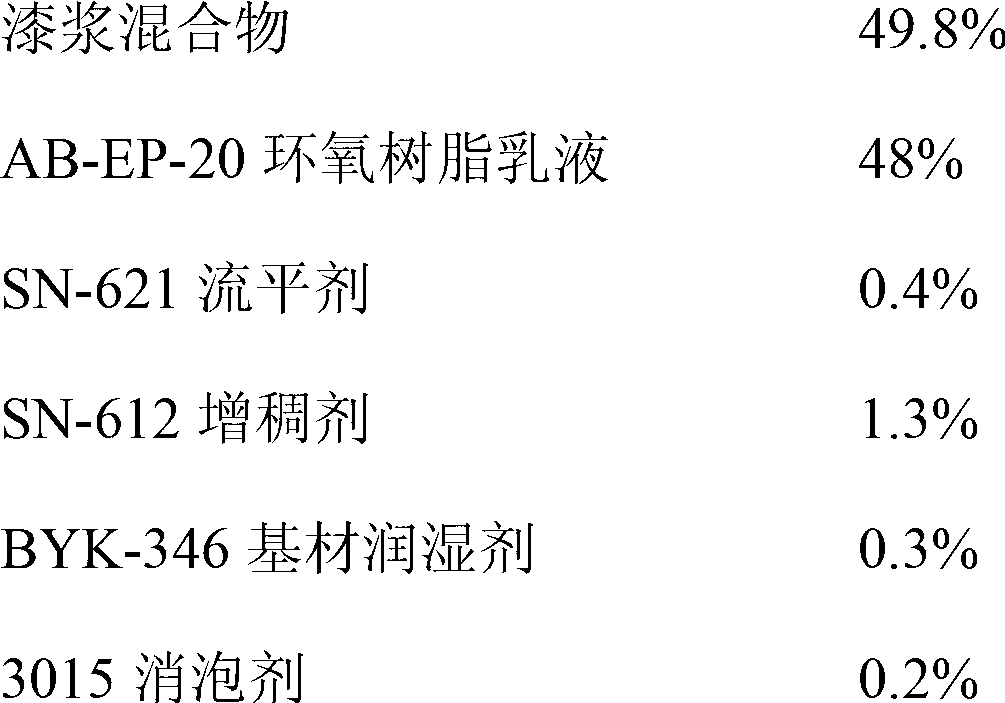

[0096] 1) The component A includes the following components by mass percentage:

[0097]

[0098] The sum of the above components is 100%;

[0099] Wherein, the millbase mixture comprises the following components by mass percentage:

[0100]

[0101]

[0102] 2) The B component is water-based epoxy curing agent AB-HGT.

[0103] The preparation method is the same as in Example 1.

Embodiment 3

[0105] A kind of waterborne epoxy antirust paint, described antirust paint is made up of A component and B component by mass ratio 2:1:

[0106] 1) The component A includes the following components by mass percentage:

[0107]

[0108] The sum of the above components is 100%;

[0109] Wherein, the millbase mixture comprises the following components by mass percentage:

[0110]

[0111] 2) The B component is water-based epoxy curing agent AB-HGA.

[0112] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com