Technology for comprehensively recovering complex material containing lead, bismuth, cobalt and nickel through wet method

A complex and high-quality material technology, which is applied in the field of comprehensive recovery of complex materials containing lead, bismuth, cobalt, and nickel, can solve problems such as difficulty in forming production capacity, and achieve the effects of wide adaptability, simple operation, and less auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Material composition: lead: 27.64%, bismuth: 12.60%, cobalt: 9.21%, nickel: 16.38%.

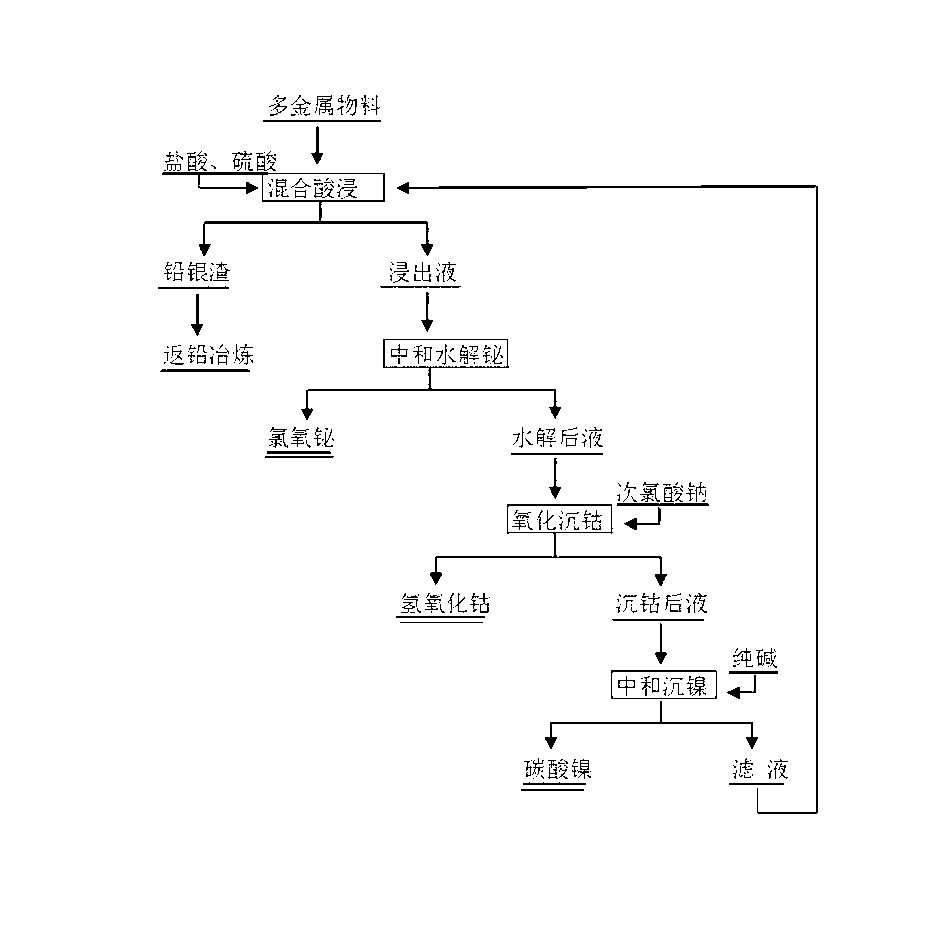

[0038] The implementation of this material adopts the production process such as figure 1 , after drying and crushing to 160 mesh, take 1.5kg of material and react for 4 hours under the conditions of sulfuric acid concentration 2.5mol / L, hydrochloric acid concentration 1.0mol / L, liquid-solid ratio 4:1, temperature 90°C, pH<0 when the reaction is complete, and filter Finally, take the reaction solution and add 3.0mol / L lye to adjust the pH to 2.0. At room temperature, add water to adjust the pH to 3. Continue to stir and react for 1 hour. After filtering, add sodium hypochlorite solution to the filtrate, and slowly add lye to adjust the pH to 4. Precipitate cobalt, continue stirring and reacting at a temperature of 55°C for 2 hours, add soda ash to the filtrate after filtration to adjust pH=10, continue stirring and reacting at a temperature of 50°C for 1 hour, and then filter. Obtain ...

Embodiment 2

[0042] Material composition: lead: 38.53%, bismuth: 18.34%, cobalt: 15.09%, nickel: 20.61%.

[0043] The implementation of this material adopts the production process such as figure 1 , after drying and crushing to 200 mesh, take 2.2kg of material in the conditions of sulfuric acid concentration 2.6mol / L, hydrochloric acid concentration 1.2mol / L, liquid-solid ratio 4:1, temperature 93℃, reaction time 4h, reaction complete pH<0, filter Finally, take the reaction solution and add 3.0mol / L lye to adjust the pH=2.0. At room temperature, add water to adjust the pH=2.5. Continue to stir and react for 1 hour. After filtering, add sodium hypochlorite solution to the filtrate, and slowly add lye to adjust the pH=4. Precipitate cobalt, continue to stir and react at a temperature of 50°C for 2 hours, add soda ash to the filtrate after filtration to adjust pH=9.5, continue to stir and react for 1 hour at a temperature of 45°C, and then filter. Obtain lead slag, bismuth oxychloride, cobal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com