Method for installing optical fiber sensor for natural gas pipeline leakage optical fiber monitoring system

A technology for optical fiber sensors and natural gas pipelines, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc. Excellent sensitivity and noise isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

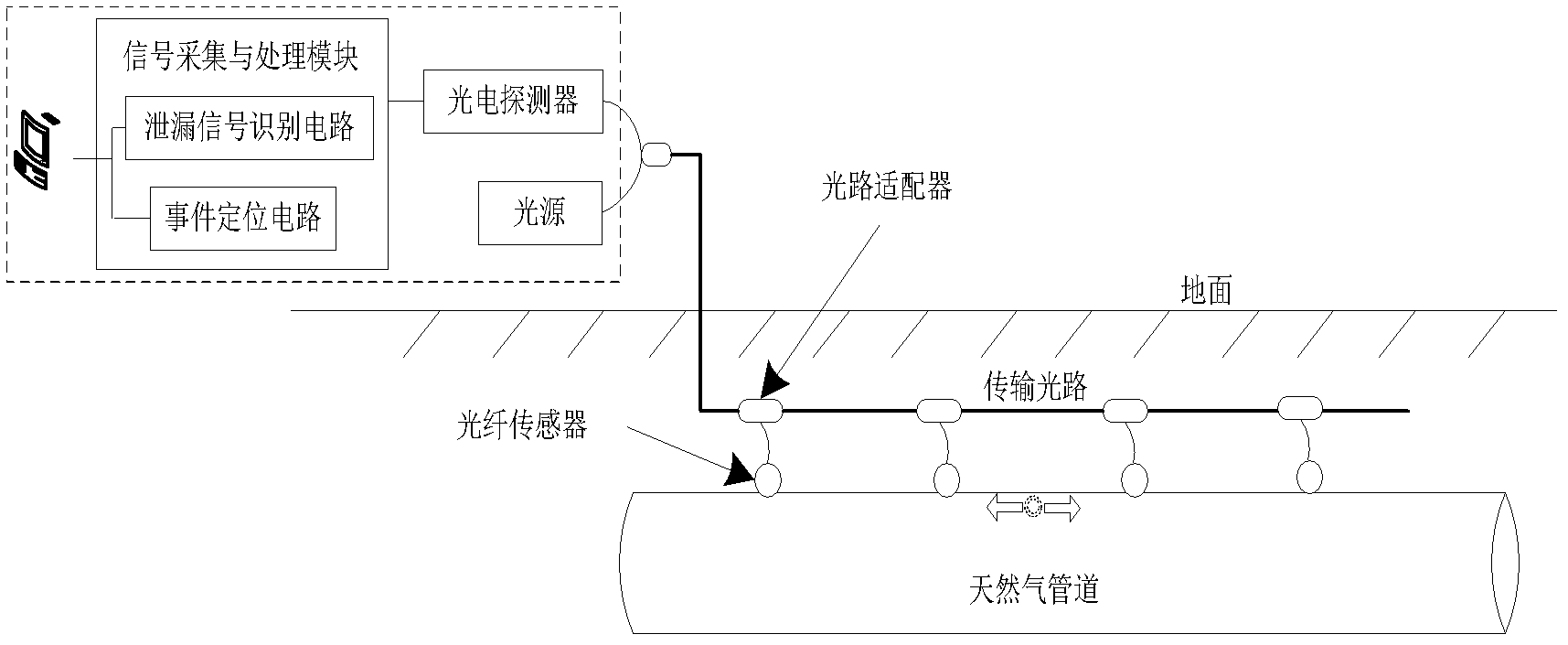

[0024] Embodiment. This example is mainly designed for the sensor of the optical fiber monitoring system for natural gas pipeline leakage, so it needs to be carried out on the basis of the embodiment of the monitoring system. The monitoring system consists of figure 1 As shown, a fiber optic sensor is installed on the pipeline body every 1.5km, and a total of 10 sensors are installed. The first 5 sensors and the last 5 sensors form a sensor group respectively, and all fiber optic sensor groups share one fiber in the transmission cable with the The light source connection of the system is used as a launch fiber, and each fiber sensor group uses one fiber in the transmission cable to connect to the system photodetector as a return fiber; the output terminal of the photodetector includes the functions of leakage signal identification and event location The signal acquisition and processing module, the signal acquisition and processing module includes a signal conditioner, a signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com