Optical proximity correction mask

An optical proximity correction and mask technology, applied in the field of optical lithography, can solve the problems such as the pattern cannot be transferred smoothly, reduce the mask process tolerance, etc., and achieve the effects of reducing light intensity, improving contour, and increasing contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The optical proximity correction mask of the embodiment of the present invention is described below. However, it can be easily understood that the embodiments provided in the present invention are only used to illustrate the making and use of the present invention in a specific way, and are not intended to limit the scope of the present invention.

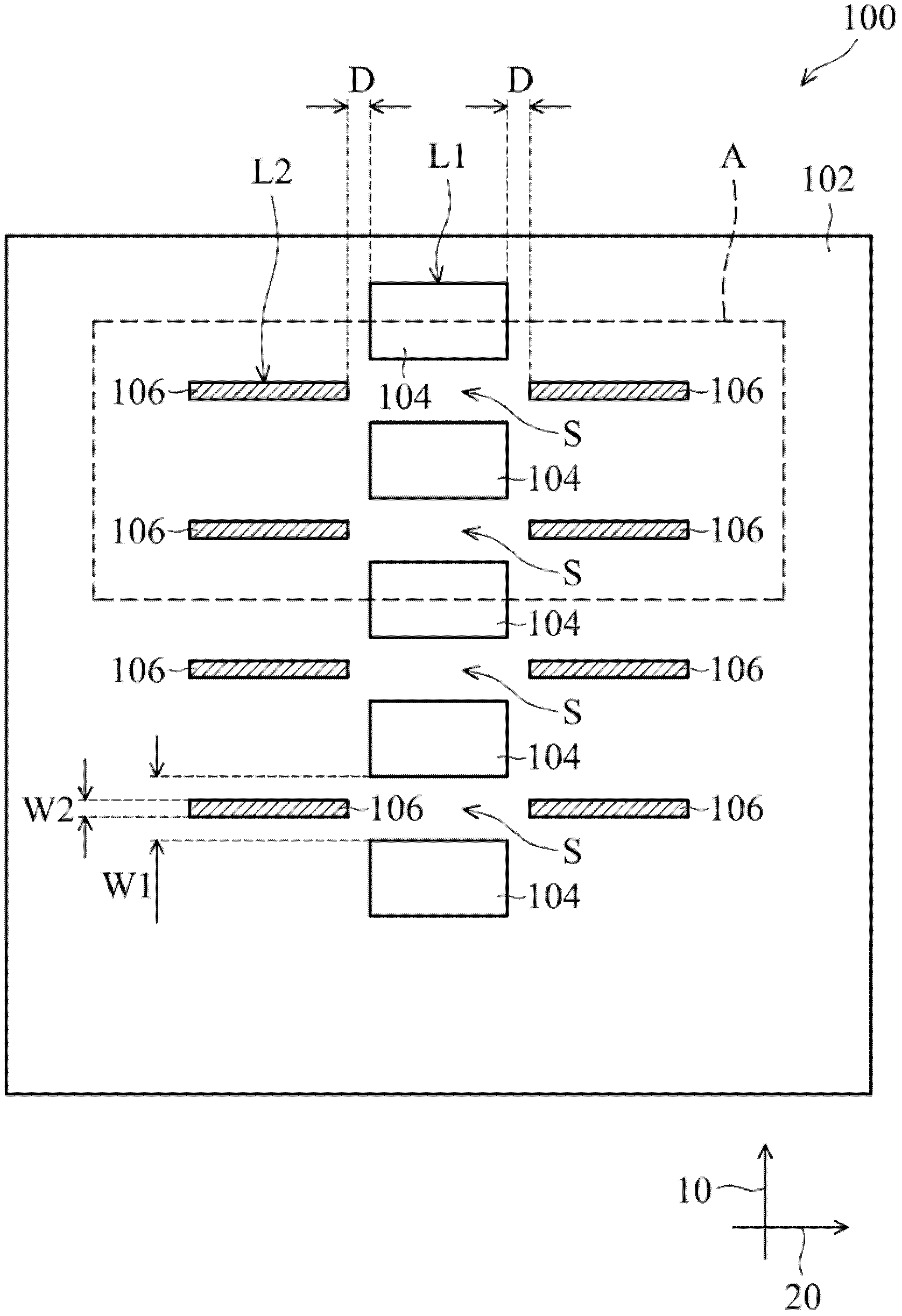

[0029] Please refer to figure 1 , which shows a schematic plan view of the optical proximity correction mask 100 according to an embodiment of the present invention. In this embodiment, the optical proximity correction mask 100 is used to manufacture a semiconductor feature pattern, such as a contact hole, which includes a plurality of opening patterns 104 and a plurality of pairs of scattering bar patterns 106 . These opening patterns 104 are arranged on a substrate 102 (for example, quartz or glass) along a first direction 10, and the substrate 102 is coated with a layer of patterned opaque material (for example, chromium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com