Sea mud substitute for young stichopus japonicus feeds

A substitute and sea mud technology, applied in animal feed, animal feed, application, etc., can solve problems such as difficult risk control, unfavorable production, and weak resistance of young ginseng, and achieve the effects of improving the environment, promoting food intake, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

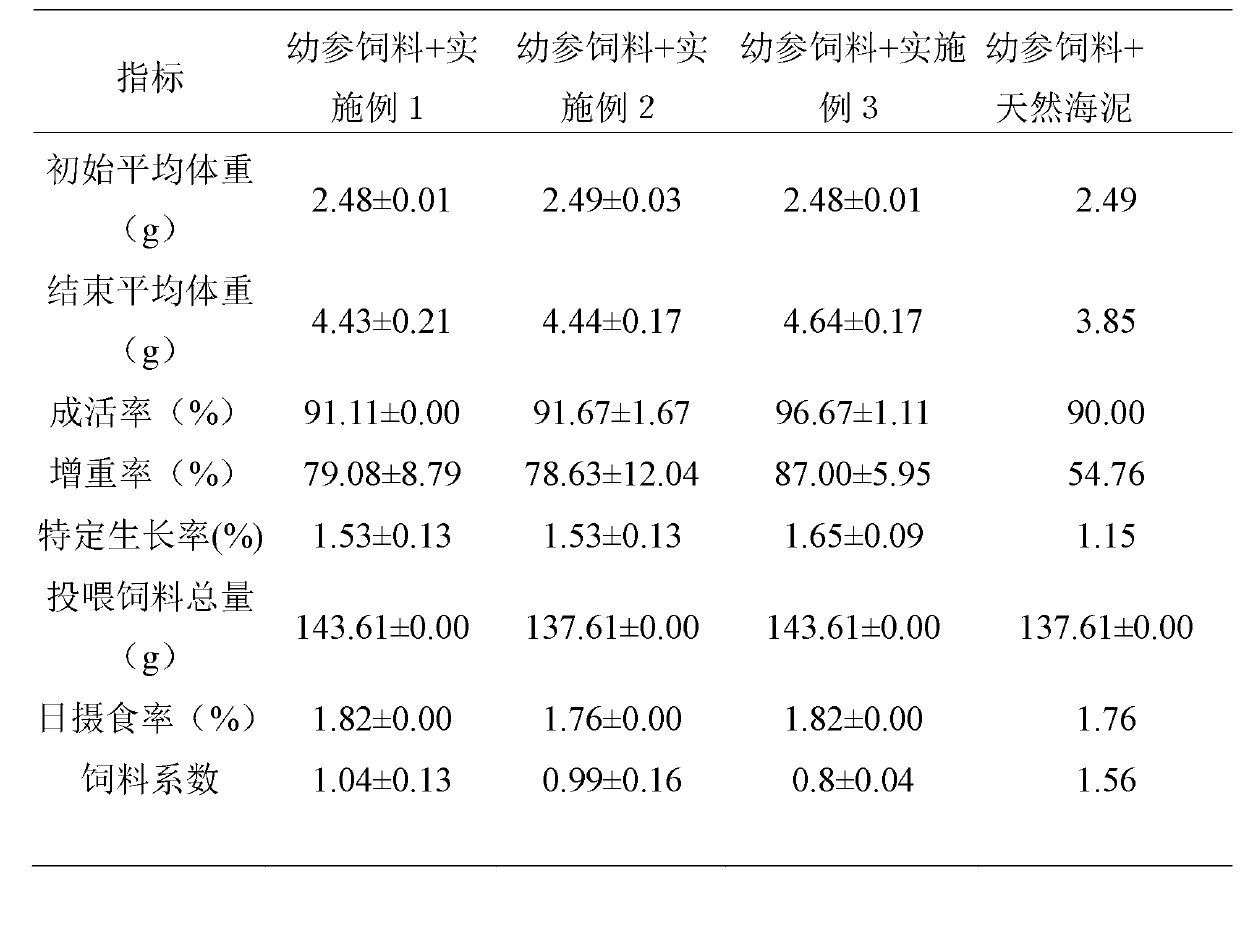

Examples

Embodiment 1

[0023] Embodiment 1 (no algae powder component)

[0024] The components of the sea mud substitute include 450g zeolite, 150g bentonite, 60g shell powder, 50g medical stone, 30g activated carbon powder, 50g multivitamin, 100g natural sea mud powder, 60g compound mineral, 50g ebony chips; a total of 1000g, will After the components are mixed, they are crushed to a size above 200 mesh.

[0025] Bentonite, zeolite, medical stone, activated carbon powder, and ebony chips are all purchased by Qingdao Qihao Biological Company from related production enterprises;

[0026] The shell powder is mixed and pulverized after washing and air-drying 28.2g oyster shells, 15g scallop shells and 16.8g clam shells;

[0027] Activated carbon powder is made by mixing and pulverizing 15.6g of bamboo charcoal, 7.8g of coconut shell activated carbon and 6.6g of apricot shell activated carbon;

[0028] The composition and content of the multivitamins are 6g vitamin A; 14g vitamin B 1 ; 8g vitamin C; ...

Embodiment

[0032] Embodiment 2 (no algae powder component)

[0033] The components of the sea mud substitute include 450g zeolite, 200g bentonite, 30g shell powder, 50g medical stone, 30g activated carbon powder, 50g multivitamin, 100g natural sea mud powder, 60g compound mineral, 30g ebony chips; a total of 1000g, will After the components are mixed, they are crushed to a size above 200 mesh.

[0034] Bentonite, zeolite, medical stone, activated carbon powder, and ebony chips are all purchased by Qingdao Qihao Biological Company from related production enterprises;

[0035] The shell powder is mixed and pulverized after washing and air-drying 10.5g oyster shells, 10.5g scallop shells and 9g clam shells;

[0036] Activated carbon powder is made by mixing and pulverizing 13.8g of bamboo charcoal, 7.8g of coconut shell activated carbon and 8.4g of apricot shell activated carbon;

[0037] The natural sea mud powder is obtained by filtering, cooking, disinfecting and air-drying the sea mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com