Synthetic method of magnetic graphene mesoporous material used for separation and enrichment in peptideomics

A technology of separation, enrichment and synthesis method, which is applied in the field of synthesis of magnetic graphene mesoporous materials, can solve the problems of small surface area and limited functional groups, and achieve the effect of maintaining biological activity, facilitating adsorption, and large surface area and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

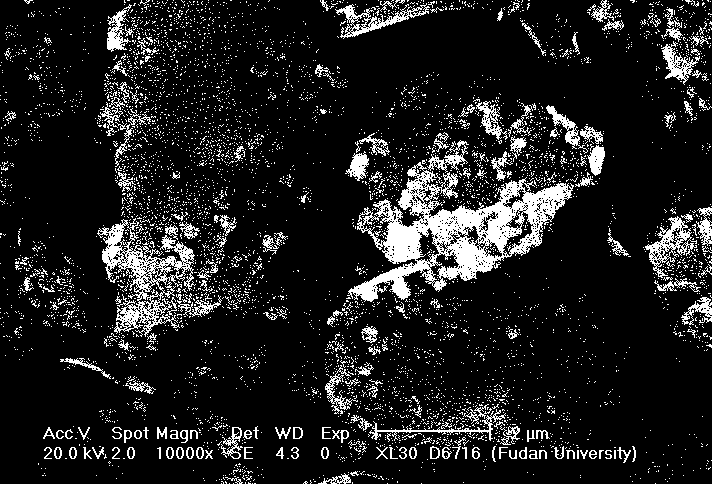

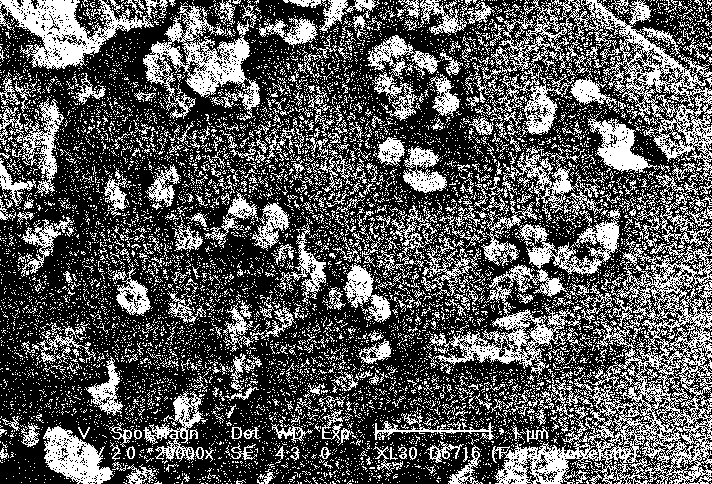

Image

Examples

Embodiment 1

[0026] (1) Disperse graphene in concentrated nitric acid, mechanically stir at 60°C for 6 hours, add sodium hydroxide solution dropwise until it becomes moderately acidic, and dry it.

[0027] (2) 800mg FeCl 3 ·6H 2 Dissolve O in ethylene glycol, add 0.15g of sodium citrate and 150mg of acidified graphene obtained in step (1), and ultrasonically disperse for two hours, then add 3.5g of sodium acetate and 2g of PEG-20000, and heat in a reactor at 200°C High pressure reaction for 8-12 hours.

[0028] (3) Disperse 50mg of hydrophilic magnetic graphene and 500mg of cetyltrimethylammonium bromide surfactant obtained in step (2) into 50ml of deionized water and ultrasonicate for half an hour, add 400ml of deionized water and 50ml 0.01M sodium hydroxide solution, after ultrasonication for 10 minutes, add 2.5ml ethyl orthosilicate ethanol solution (volume ratio of ethyl orthosilicate: ethanol is 1:4), mechanically stir at 60°C for 12 hours, wash and dry.

[0029] (4) Wash off the c...

Embodiment 2

[0033] (1) Disperse graphene in concentrated nitric acid, mechanically stir at 60°C for 6 hours, add sodium hydroxide solution dropwise until it becomes moderately acidic, and dry it.

[0034] (2) Add 200mg FeCl 3 ·6H 2 Dissolve O in ethylene glycol, add 0.15g of sodium citrate and 150mg of acidified graphene obtained in step (1), and ultrasonically disperse for two hours, then add 3.5g of sodium acetate and 2g of PEG-20000, and heat in a reactor at 200°C High pressure reaction for 8-12 hours.

[0035](3) Disperse 50mg of hydrophilic magnetic graphene and 500mg of sodium dodecylbenzenesulfonate surfactant obtained in step (2) into 50ml of deionized water and ultrasonicate for half an hour, add 400ml of deionized water and 50ml of 0.01M Sodium hydroxide solution, after ultrasonication for 10 minutes, add 2.5ml ethyl orthosilicate ethanol solution (volume ratio of ethyl orthosilicate: ethanol is 1:4), mechanically stir at 60°C for 12 hours, wash and dry.

[0036] (4) Wash awa...

Embodiment 3

[0039] (1) Disperse graphene in concentrated nitric acid, mechanically stir at 60°C for 6 hours, add sodium hydroxide solution dropwise until it becomes moderately acidic, and dry it.

[0040] (2) Add 600mg FeCl 3 ·6H 2 Dissolve O in ethylene glycol, add 0.15g of sodium citrate and 150mg of acidified graphene obtained in step (1), and ultrasonically disperse for two hours, then add 3.5g of sodium acetate and 2g of PEG-20000, and heat in a reactor at 200°C High pressure reaction for 8-12 hours.

[0041] (3) Disperse 50mg of hydrophilic magnetic graphene and 500mg of stearic acid surfactant obtained in step (2) into 50ml of deionized water and ultrasonicate for half an hour, add 400ml of deionized water and 50ml of 0.01M sodium hydroxide solution, After ultrasonication for 10 minutes, add 2.5ml ethyl orthosilicate ethanol solution (volume ratio of ethyl orthosilicate: ethanol is 1:4), mechanically stir at 60°C for 12 hours, wash and dry.

[0042] (4) Wash away the stearic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com