Titanium-based carbon nanotube supported copper/palladium bimetallic catalyst and preparation method thereof

A technology of bimetallic catalysts and carbon nanotubes, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of high cost and time-consuming, and achieve mechanical Good performance, good electrical performance, and the effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

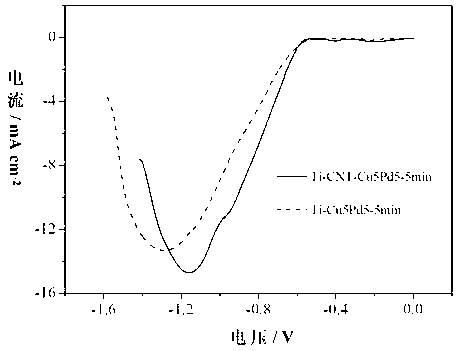

Embodiment 1

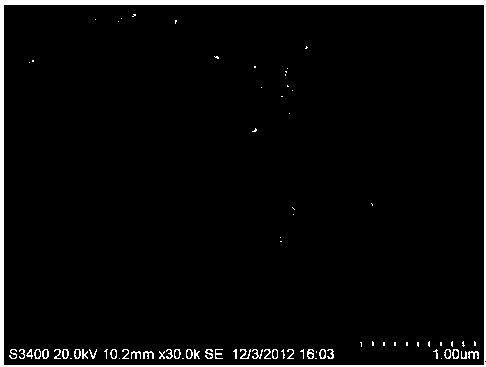

[0023] 1) Take 0.2 g of carbon nanotubes and place them in a mixed concentrated acid with the ratio of concentrated sulfuric acid and concentrated nitric acid at a ratio of 3:1, ultrasonicate at a constant temperature of 60 °C for 8 h, wash and filter with deionized water until the pH value of the filtrate is neutral, and dry at low temperature. Obtain functional grouped carbon nanotube materials; ultrasonically disperse in deionized water, and obtain 100 mL of carbon nanotube suspension at constant volume, the concentration of carbon nanotubes in the suspension is about 2 mg / L;

[0024] 2) The titanium plate was polished until the surface showed a uniform light gray luster; the polished titanium plate was washed with 50 wt% NaOH alkali at 70 °C for 1 h to remove the surface oil; the alkali-washed titanium plate was used at 80 °C Pickling with 20 wt% oxalic acid for 2 h to remove surface TiO 2 ;

[0025] 3) The titanium plate pretreated in step 2) was used as the anode, the P...

Embodiment 2

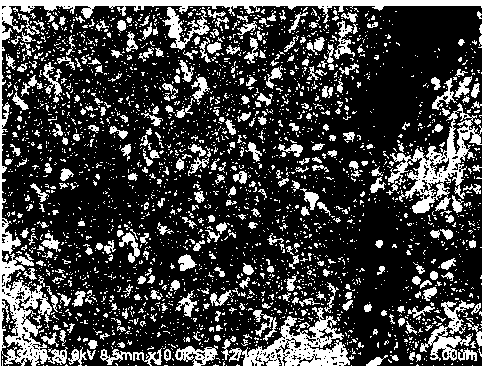

[0029] 1) Take 0.2 g of carbon nanotubes and place them in a mixed concentrated acid with the ratio of concentrated sulfuric acid and concentrated nitric acid at a ratio of 3:1, ultrasonicate at a constant temperature of 70 °C for 6 h, wash and filter with deionized water until the pH value of the filtrate is neutral, and dry at low temperature. Obtain functional grouped carbon nanotube materials; ultrasonically disperse in deionized water, and obtain 100 mL of carbon nanotube suspension at constant volume, the concentration of carbon nanotubes in the suspension is about 2 mg / L;

[0030] 2) The titanium plate was polished until the surface showed a uniform light gray luster; the polished titanium plate was washed with 30 wt% NaOH alkali at 90 °C for 2 h to remove surface oil; the titanium plate after alkali washing was used at 95 °C Pickling with 10 wt% oxalic acid for 4 h to remove surface TiO 2 ;

[0031] 3) The titanium plate pretreated in step 2) was used as the anode, th...

Embodiment 3

[0035] 1) Take 0.2 g of carbon nanotubes and place them in a mixed concentrated acid with the ratio of concentrated sulfuric acid and concentrated nitric acid at a ratio of 3:1, ultrasonicate at a constant temperature of 65 °C for 7 h, wash and filter with deionized water until the pH value of the filtrate is neutral, and dry at low temperature. Obtain functional grouped carbon nanotube materials; ultrasonically disperse in deionized water, and obtain 100 mL of carbon nanotube suspension at constant volume, the concentration of carbon nanotubes in the suspension is about 2 mg / L;

[0036] 2) The titanium plate was polished until the surface showed a uniform light gray luster; the polished titanium plate was washed with 40 wt% NaOH alkali at 80 °C for 1.5 h to remove surface oil; the titanium plate after alkali washing was used at 90 °C Pickling with 15 wt% oxalic acid for 3 h to remove surface TiO 2 ;

[0037] 3) The titanium plate pretreated in step 2) was used as the anode, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com