Composite polyolefin material, preparation method and use of composite polyolefin material

A technology for compounding polyolefin and polyolefin, which is applied in chemical instruments and methods, on-site preparation of building components, synthetic resin layered products, etc. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

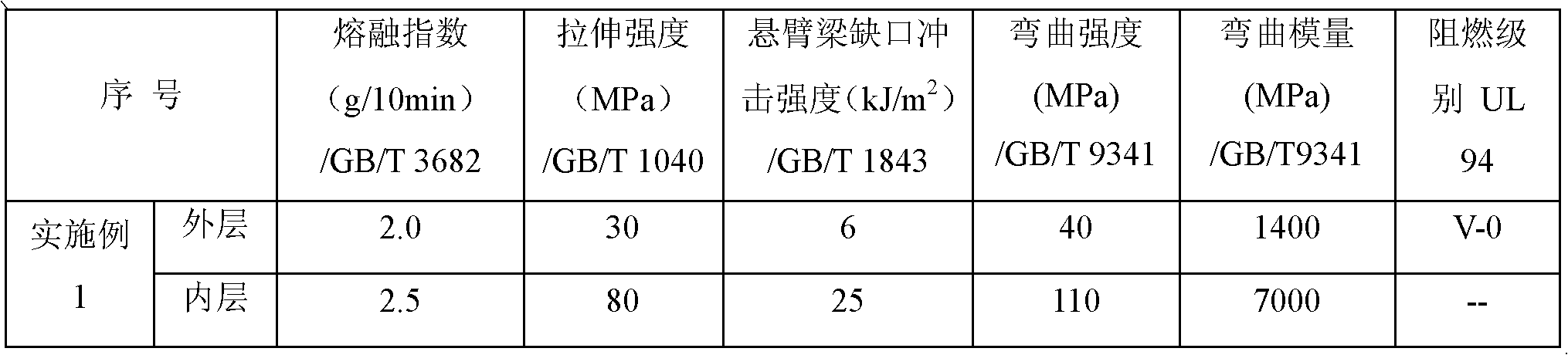

Examples

Embodiment 1

[0054] (1) The proportion of each component of the outer layer material is as follows:

[0055] Polypropylene: 64.8 parts,

[0056] Nitrogen-phosphorus halogen-free flame retardant: 35 parts,

[0057] Antioxidant 1010: 0.1 parts,

[0058] Lubricant EBS: 0.1 parts,

[0059] Among them, the nitrogen-phosphorus halogen-free flame retardant is a compound of ammonium polyphosphate and melamine urate, and the compounding ratio is 2:1;

[0060] The above-mentioned mixture is fed into the twin-screw extruder by a feeder with precise metering, and is sheared at high speed by the twin-screw, kneaded, extruded from the machine head, drawn, air-cooled, pelletized and dried; the twin-screw The technological parameters of the screw extruder are as follows: the temperature of each section of the screw should be controlled between 170 and 190 °C.

[0061] (2) The proportion of each component of the inner layer material is as follows:

[0062] Polypropylene: 50 parts,

[0063] Glass fibe...

Embodiment 2

[0071] (1) The proportion of each component of the outer layer material is as follows:

[0072] Polypropylene: 56.2 parts,

[0073] Talcum powder: 20 parts,

[0074] Decabromodiphenylethane: 18 parts,

[0075] Antimony trioxide: 5 parts,

[0076] Antioxidant 1010: 0.2 parts,

[0077] Antioxidant 168: 0.2 parts,

[0078] Lubricant EBS: 0.4 parts;

[0079] The above-mentioned mixture is fed into the twin-screw extruder by a feeder with precise metering, and is sheared at high speed by the twin-screw, kneaded, extruded from the machine head, drawn, air-cooled, pelletized and dried; the twin-screw The technological parameters of the screw extruder are as follows: the temperature of each section of the screw should be controlled between 170 and 190 °C.

[0080] (2) The proportion of each component of the inner layer material is as follows:

[0081] Polypropylene: 69.5 parts,

[0082] Mica: 30 parts,

[0083] Antioxidant 1010: 0.1 parts,

[0084] Antioxidant 168: 0.1 parts...

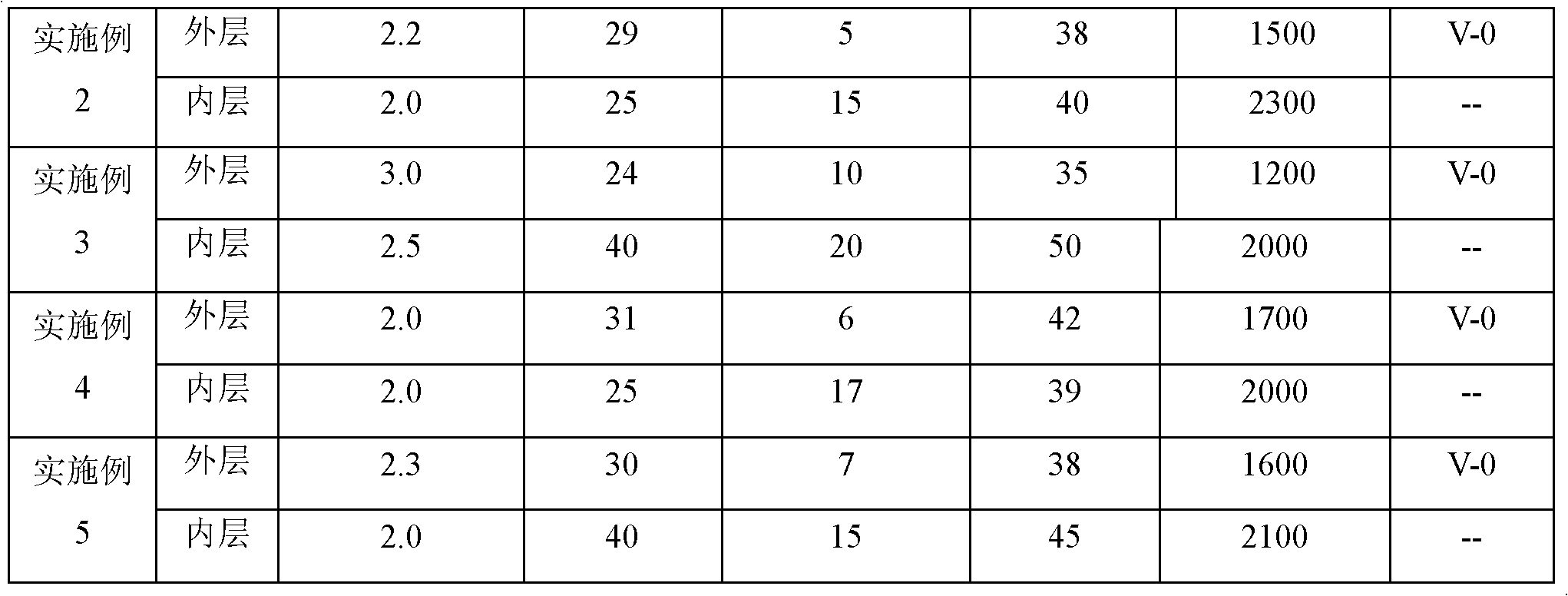

Embodiment 3

[0090] (1) The proportion of each component of the outer layer material is as follows:

[0091] Polypropylene: 79.4 parts,

[0092] Octabromoether: 16 parts,

[0093] Antimony trioxide: 4 parts,

[0094] Antioxidant 1010: 0.1 parts,

[0095] Antioxidant 168: 0.1 parts,

[0096] Lubricant EBS: 0.4 parts;

[0097] The above-mentioned mixture is fed into the twin-screw extruder by a feeder with precise metering, and is sheared at high speed by the twin-screw, kneaded, extruded from the machine head, drawn, air-cooled, pelletized and dried; the twin-screw The technological parameters of the screw extruder are as follows: the temperature of each section of the screw should be controlled between 170 and 190 °C.

[0098] (2) The proportion of each component of the inner layer material is as follows:

[0099] Polypropylene: 77.7 parts,

[0101] E-glass fiber: 10 parts,

[0102] Bismaleimide: 2 parts,

[0103] Antioxidant 1010: 0.1 parts,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com