Down feather lyocell and processing method thereof

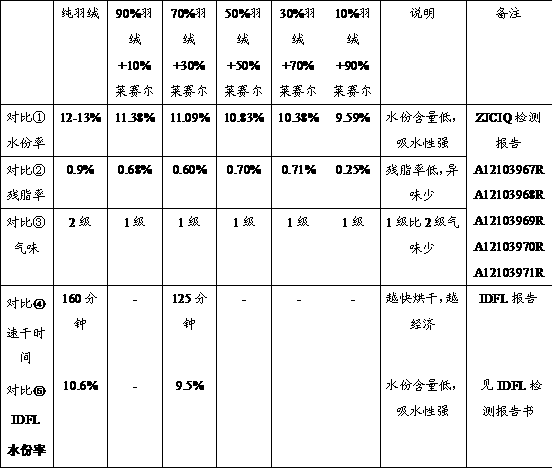

A processing method, lyocell technology, applied in home appliances, loose filling materials, applications, etc., can solve the problem of unsatisfactory bulkiness and warmth retention of pure lyocell filling materials, high cost of pure down filling materials, and easy to be infected by bacteria Invasion and other problems, to achieve excellent moisture absorption performance, outstanding performance, reduce the effect of unpleasant smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A processing method of down lyocell, comprising the following steps:

[0029] Step a. Opening of lyocell filler: Spread 90kg of lyocell raw material fibers evenly on the platform of the opener, start the opener, and the opener will loosen the raw material fibers and transfer them to the conveyor pipeline; at the same time, 10kg of finished down is sent into the conveying pipeline, and the dispersed lyocell raw material fiber and finished down are mixed in the pipeline and transported to the mixing sprayer together;

[0030] Step b. Spraying: The mixed two raw materials are sent to the mixing and spraying machine for stirring, and mixed at 5-6 kg / cm 2 The air pressure sprays the treatment liquid evenly in the form of mist into the mixing sprayer. The treatment liquid contains 17.5kg of water, 0.875kg of industrial alcohol, and antistatic agent (octylphenol polyoxyethylene ether TX-10): 0.298kg ; Mix the two evenly, spray for 10 minutes, and continue stirring for 5 minut...

Embodiment 2

[0035] A processing method of down lyocell, comprising the following steps:

[0036] Step a. Opening of lyocell filler: Spread 70kg of lyocell raw material fibers evenly on the platform of the opener, start the opener, and the opener will loosen the raw material fibers and then transfer them to the conveyor pipeline; at the same time, 30kg of finished down is sent into the conveying pipeline, and the dispersed lyocell raw material fiber and finished down are mixed in the pipeline and transported to the mixing sprayer together;

[0037] Step b. Spraying: The mixed two raw materials are sent to the mixing and spraying machine for stirring, and mixed at 5-6 kg / cm 2 The air pressure sprays the treatment liquid evenly in the form of mist into the mixing sprayer. The treatment liquid contains 17.5kg of water, 0.875kg of industrial alcohol, and antistatic agent (octylphenol polyoxyethylene ether TX-10): 0.298kg ; Mix the two evenly, spray for 10 minutes, and continue stirring for 5 ...

Embodiment 3

[0042] A processing method of down lyocell, comprising the following steps:

[0043] Step a. Opening of lyocell filler: Spread 50kg of lyocell raw material fibers evenly on the platform of the opener, start the opener, and the opener will loosen the raw material fibers and transfer them to the conveyor pipeline; at the same time, 50kg of finished down is sent into the conveying pipeline, and the dispersed lyocell raw material fiber and finished down are mixed in the pipeline and transported to the mixing sprayer together;

[0044] Step b. Spraying: The mixed two raw materials are sent to the mixing and spraying machine for stirring, and mixed at 5-6 kg / cm 2 The air pressure sprays the treatment liquid evenly in the form of mist into the mixing sprayer. The treatment liquid contains 17.5kg of water, 0.875kg of industrial alcohol, and antistatic agent (octylphenol polyoxyethylene ether TX-10): 0.298kg ; Mix the two evenly, spray for 10 minutes, and continue stirring for 5 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com