Method for preparing composite waste plastic powder suitable for coal water slurry from waste traditional Chinese medicine residues and activated carbon

A technology for activated carbon preparation and waste plastics, which is applied in the direction of waste fuel, solid waste removal, chemical instruments and methods, etc. It can solve the problems of product quality impact, pollution, and difficulty in guaranteeing the quality of plastic products, so as to achieve thorough treatment and improve stability , highlighting the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

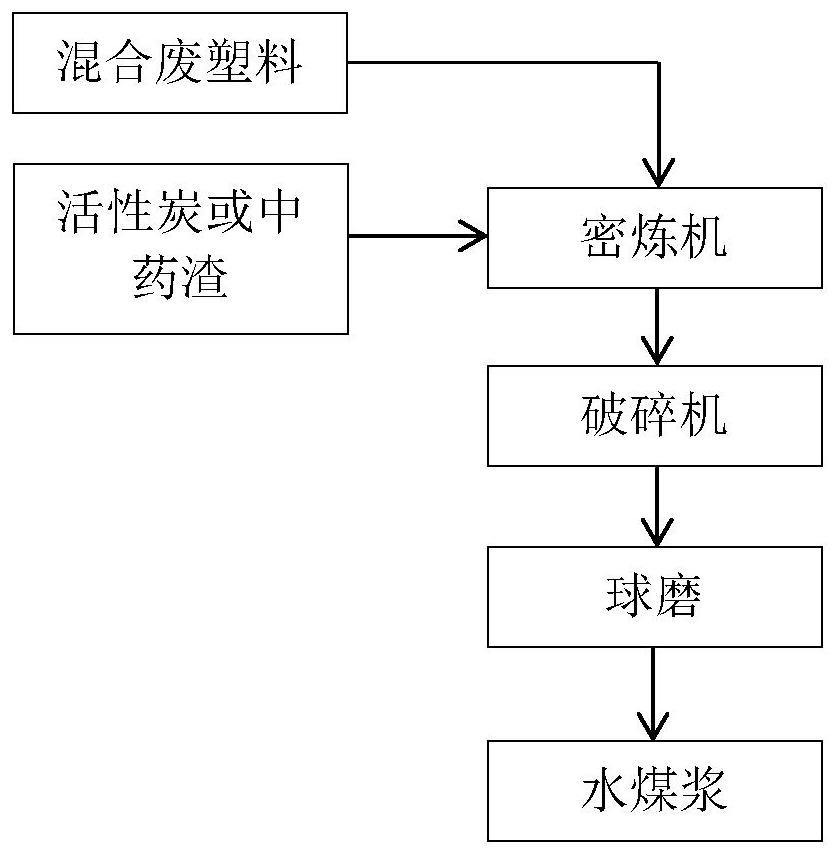

Method used

Image

Examples

Embodiment 1

[0026] (1) Waste polyethylene packaging barrels, polypropylene waste packaging bags, and polyester waste packaging bottles, each of which has a mass of 50g, and the waste plastics are chopped and mixed;

[0027] (2) Heating to 165°C in the internal mixer, compacting and heating for 2 hours, the material in the internal mixer becomes fluid.

[0028] (3) Add 150g of waste medicine dregs, raise the temperature to 200°C, knead and stir evenly, continue heating for 1 hour, turn on the internal mixer, and cool the discharged material to room temperature.

[0029] (4) After the material is crushed by a crusher, it is added to a ball mill and ground to 200 mesh with a pass rate of 50%. After mixing with dry coal at a ratio of 1:9, add 2000g of water and 50g of 40% NDF type coal-water slurry additive to prepare Coal water slurry, the key indicators of the prepared coal water slurry are:

[0030] Solid content: 62.31%, viscosity: 596mPa.S, calorific value: 3950Kcal / Kg

Embodiment 2

[0032] (1) Waste polyethylene packaging barrels, polypropylene waste packaging bags, and polyester waste packaging bottles, the masses of which are 160g, 20g, and 20g respectively, and the waste plastics are chopped and mixed;

[0033] (2) Heating to 180°C in the internal mixer, compacting and heating for 2.5 hours, the material in the internal mixer becomes fluid.

[0034] (3) Add 200g of traditional Chinese medicine dregs, mix and stir evenly, continue heating at 195°C for 1 hour, turn on the internal mixer, and cool the material to room temperature.

[0035] (4) After the material is crushed by a crusher, it is added to a ball mill and ground to 200 mesh with a pass rate of 50%. After mixing with dry coal at a ratio of 2:8, add 1200g of water and 40g of 40% NDF type coal-water slurry additive to prepare Coal water slurry, the key indicators of the prepared coal water slurry are:

[0036] Solid content: 62.46%, viscosity: 633mPa.S, calorific value: 3862Kcal / Kg

Embodiment 3

[0038] (1) Waste polyethylene packaging barrels, polypropylene waste packaging bags, and polyester waste packaging bottles. The masses of the three are 120g, 20g, and 60g respectively. The waste plastics are chopped and mixed.

[0039] (2) Heating to 170°C in the internal mixer, compacting and heating for 2.0 hours, the material in the internal mixer becomes fluid.

[0040] (3) Add 150g of activated carbon, mix and stir evenly, continue heating at 202°C for 1 hour, turn on the internal mixer, and cool the material to room temperature.

[0041] (4) After the material is crushed by a crusher, it is added to a ball mill and ground to 200 mesh with a passing rate of 50%. After mixing with dry coal at a ratio of 5:5, 700g of water and 30g of 40% NDF type coal-water slurry additive are added to prepare Coal water slurry, the key indicators of the prepared coal water slurry are:

[0042] Solid content: 60.19%, viscosity: 690mPa.S, calorific value: 3637Kcal / Kg

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com