Method for deeply dehydrating sludge by utilizing cullet

A technology of deep dewatering and waste glass, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high moisture content of sludge and high moisture content of excess sludge, achieve high organic matter content, high porosity of finished products, The effect of high dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

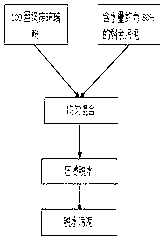

[0014] Embodiment 1: A kind of method embodiment that uses waste glass to make sludge depth dehydration, see figure 1 , the method includes adding glass powder to the sludge and extruding the sludge, wherein the sludge is first added to the glass powder for conditioning before extrusion, and the steps of the sludge deep dehydration method are:

[0015] a. Add glass powder to the remaining sludge with a moisture content of about 80%, stir and mix evenly to obtain mixed sludge, and the amount of glass powder added is 10% to 50% of the total mass of the sludge;

[0016] b. Sending the mixed sludge into a filter press for extrusion and deep dehydration to obtain dewatered sludge with a moisture content lower than 45%.

[0017] In order to obtain a good sludge dehydration effect, the waste glass needs to be treated first before being added to the sludge, otherwise the desired effect cannot be achieved. Therefore, the waste glass described in this embodiment is glass powder passed t...

Embodiment 2

[0020] Referring to Example 1, the present example is a further preferred example of the content of Example 1, therefore, the method is further as follows: the remaining sludge with a moisture content of about 80% is mixed with the glass powder of 100 mesh standard sieves , in which the amount of glass powder added is 30% of the total mass of the sludge. After stirring and mixing evenly, it is sent to a filter press to obtain dewatered sludge with a moisture content of 43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com