Microbial microcapsule anti-sulfate erosion system of structural concrete

A sulfate-resistant and microcapsule technology, which is applied in the field of concrete engineering, can solve problems such as the failure of sulfate-resistant cement to meet actual engineering needs, the inability to effectively control sulfate corrosion for a long time, and the difficulty of anti-corrosion coating construction. The anti-sulfate corrosion ability of the base is effective for a long time, avoiding the outage of rail transit lines, improving safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

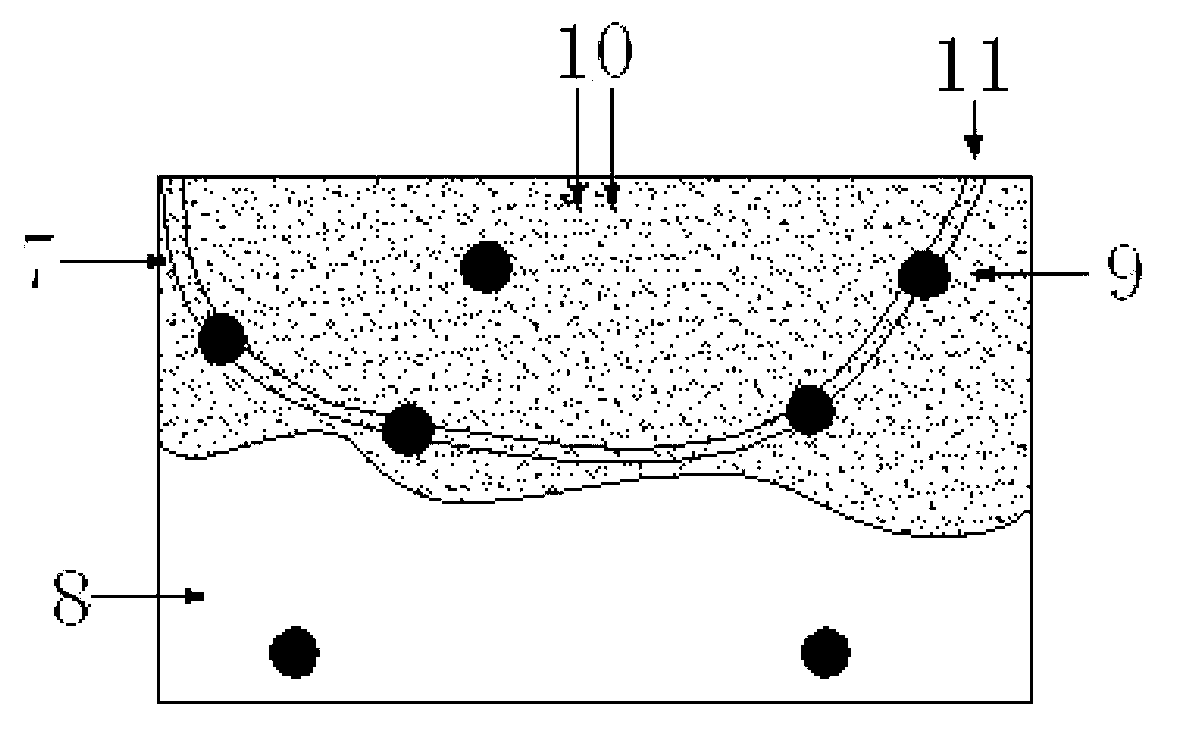

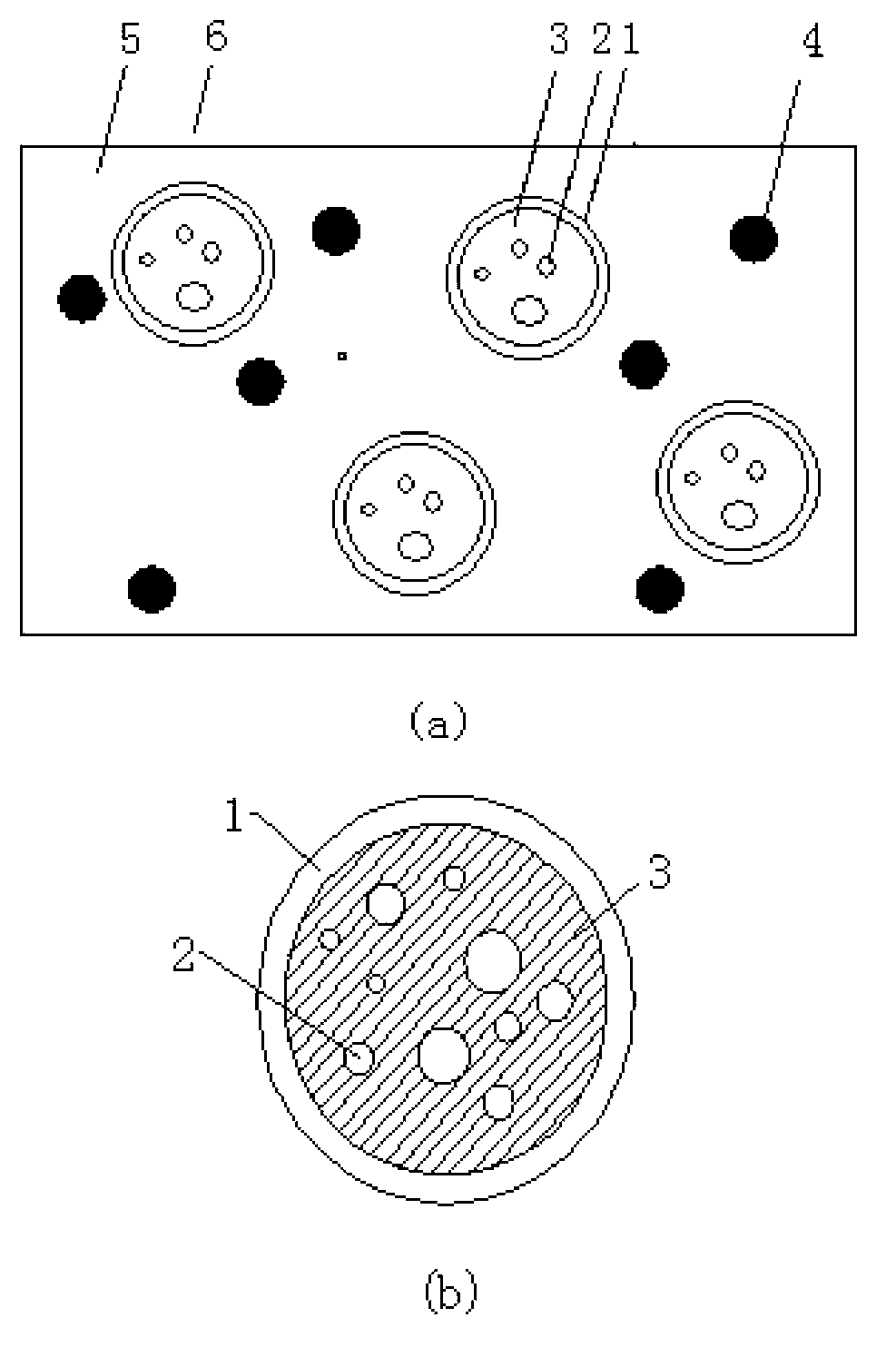

[0076] First configure the culture medium containing sulfate-reducing bacteria, the concentration of sulfate-reducing bacteria of the genus Desulfurium is 10 9 cell / ml, add K 2 HPO 4 0.5g,NH 4 Cl 1g, Na 2 SO 4 1g, CaCl 2 2H 2 O 0.1g, MgSO 4 ·7H2 O 2g, 70% sodium lactate solution 5g, distilled water 1000mL, Fe(NH 4 ) 2 (SO 4 ) 2 6H 2 O 0.2 g. Prepare microbial microcapsules by traditional in-situ polymerization method: weigh 50 grams of urea and 90 grams of formaldehyde to make a mixed solution, adjust the pH to 8-9 with dilute NaOH solution, and then conduct a heating reaction in a water bath for a period of time until it is completely dissolved to obtain a prepolymer body. Emulsify the culture medium containing sulfate-reducing bacteria in SDBS (sodium dodecylbenzenesulfonate) solution for a period of time, then add it to the prepolymer solution and adjust the pH to 2-2.5 with dilute acid solution, while raising the temperature to 55 ℃, stirred and reacted for 2...

Embodiment 2

[0081] Referring to the method in Example 1, experiments were carried out on Desulfococcus, Desulfosarcina and Desulfurina sulfate-reducing bacteria respectively. The specific experimental conditions are shown in Table 1.

[0082] Table 1

[0083]

[0084]

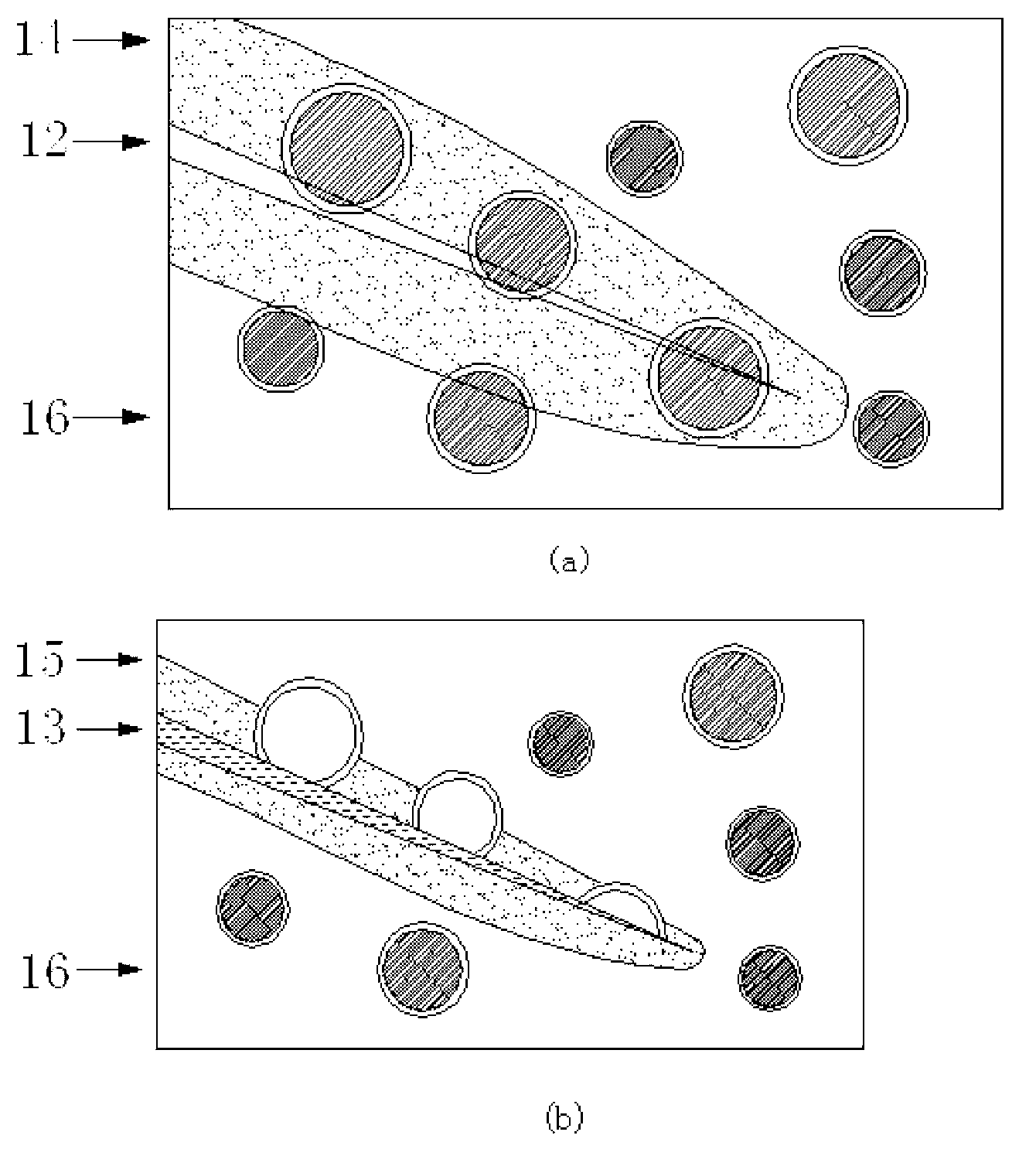

[0085] With reference to the steps of Example 1 for the microcapsules of the obtained Desulfococcus, Desulfosarcina and Desulfurina sulfate-reducing bacteria, prepare respective corresponding concrete containing microbial microcapsules, and then proceed with Example 1 The same initial damage test as in the immersion test. After observing the experimental results, it was found that sulfur precipitated on the surface of the cracks in the microcapsule concrete of the four microorganisms, and the longer the curing time, the more sulfur precipitated. The greater the initial damage, the greater the sulfur precipitation.

[0086] It can be seen that the sulfur precipitation generated by the microbial metabolism after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com