Activation strengthening agent applied to cement with high-volume limestone

A limestone and reinforcing agent technology, applied in the field of cement additives, can solve the problem of high cost and achieve the effects of low cost, compact cement structure and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of described herbal lignin-based polyol is:

[0035] Mix polyols with polyethylene glycol to obtain mixed alcohols;

[0036] reacting the mixed alcohol, herb fermentation waste residue and concentrated sulfuric acid to obtain a mixed liquor;

[0037] Adjust the pH value of the mixed solution to neutral to obtain herbal plant lignin-based polyols; the herbal plant fermentation waste residue is composed of 60wt%~70wt% lignin, 15wt%~25wt% cellulose, 2wt%~5wt% protein, 3wt%~5wt% ash, and the rest water.

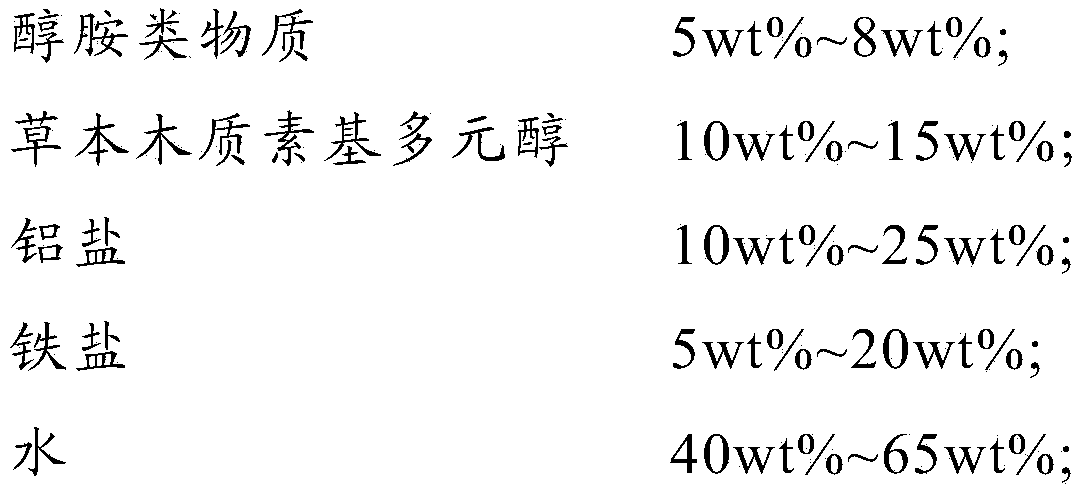

[0038] According to the present invention, the activation enhancer applied to the limestone cement with large volume includes alcohol amines, herbaceous lignin-based polyols, aluminum salts, iron salts and water.

[0039] The alcohol amines are preferably one or both of triethanolamine and triisopropanolamine. The content of the alcohol amines is 5wt%~8wt%, preferably 6wt%~7wt%. The invention reduces the content of alcohol amine substances and re...

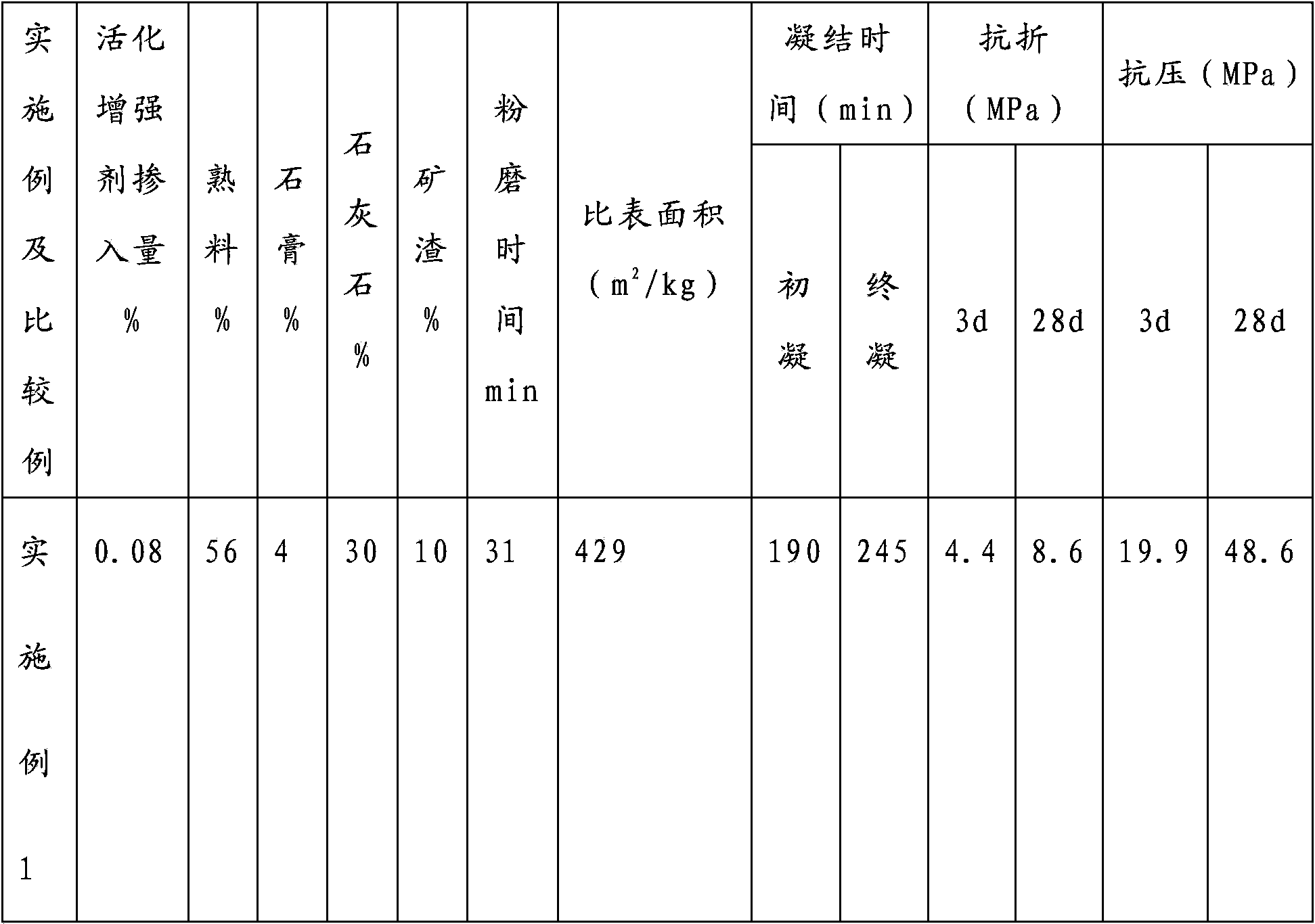

Embodiment 1

[0053] The herbaceous plant fermentation waste residue used in this example is the residue left after corn stalks are fermented to produce ethanol, consisting of 65wt% lignin, 20wt% cellulose, 3wt% protein, 3.5wt% ash, and the rest of water .

[0054] Add 300kg of polyethylene glycol 200, 300kg of ethylene glycol, and 300kg of glycerin into the reactor, stir, and mix evenly, then add 200kg of herbal plant fermentation waste residue, 16.5kg of concentrated sulfuric acid, stir, and heat to 125°C for 5 hours. Cool down to room temperature, adjust the system to neutrality with 40% sodium hydroxide solution, and obtain the herbaceous plant lignin polyol. Add 600kg of triethanolamine, 1500kg of aluminum chloride, 800kg of ferric nitrate, and 5900kg of water in sequence to obtain an activation enhancer for large-volume limestone cement.

[0055] 8kg of the obtained activation enhancer, 56kg of clinker, 4kg of gypsum, 20kg of limestone and 20kg of slag were mixed and ground for 31 mi...

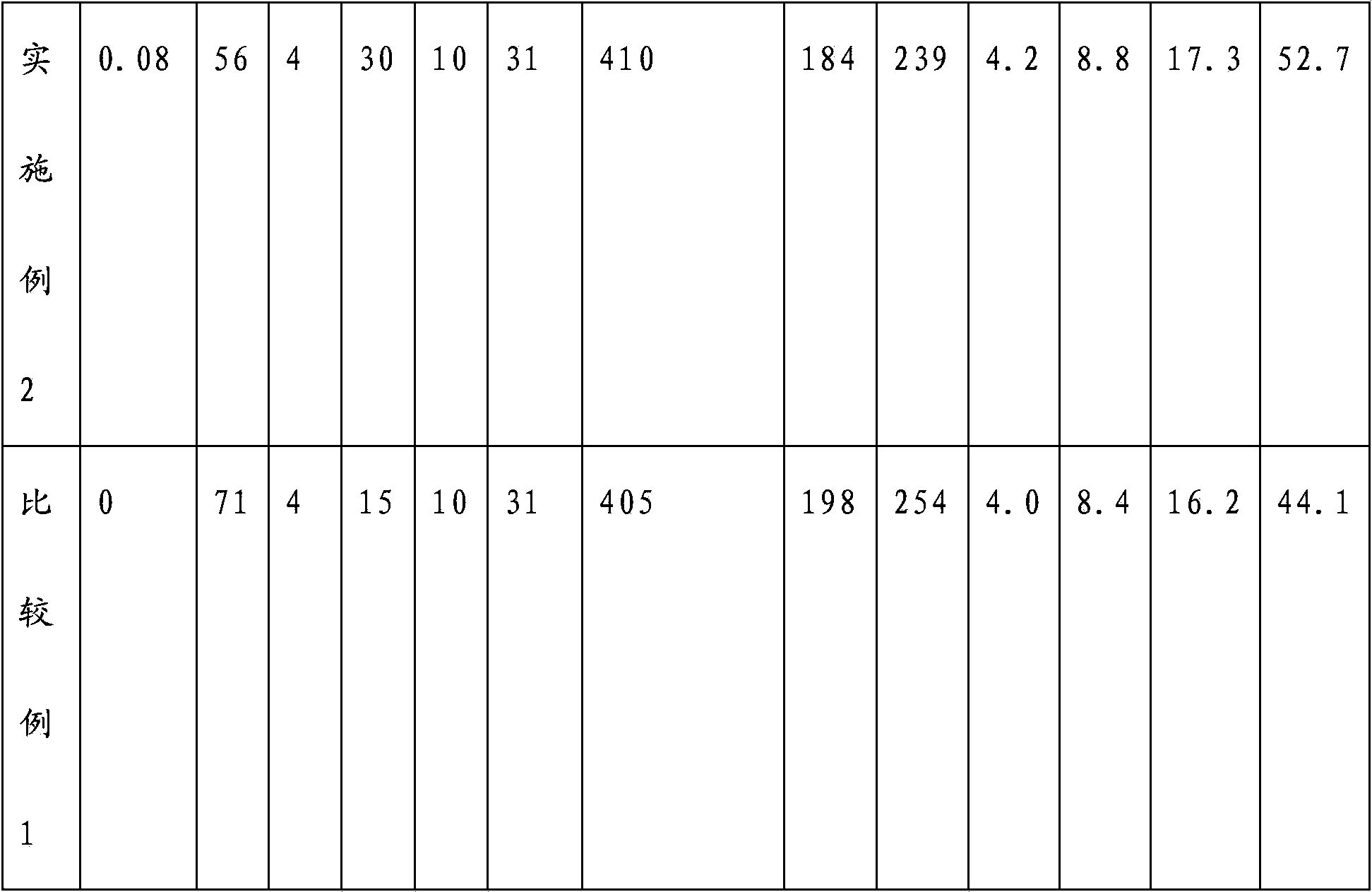

Embodiment 2

[0057] The herb fermentation waste residue used in this example is the residue left after corn stalks are fermented to produce ethanol, consisting of 65wt% lignin, 22wt% cellulose, 4wt% protein, 4% ash, and the rest water.

[0058] Add 300kg of polyethylene glycol 200, 300kg of diethylene glycol, and 300kg of glycerin into the reaction kettle, stir, mix evenly, then add 200kg of herbal plant fermentation waste residue, 16.5kg of concentrated sulfuric acid, stir, and heat to 125°C for reaction 5 Hours, down to room temperature, adjust the system to neutral with ammonia solution to obtain herbaceous plant lignin polyols. Then add 600kg of triisopropanolamine, 1500kg of aluminum sulfate, 800kg of ferric chloride, and 5900kg of water in sequence to obtain an activation enhancer for limestone cement with a large dosage.

[0059] 8kg of the obtained activation enhancer, 56kg of clinker, 4kg of gypsum, 20kg of limestone and 20kg of slag were mixed and ground for 31 minutes to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com