Modified nano-attapulgite clay inorganic thermal-insulation mortar coated with plant ash and preparation method thereof

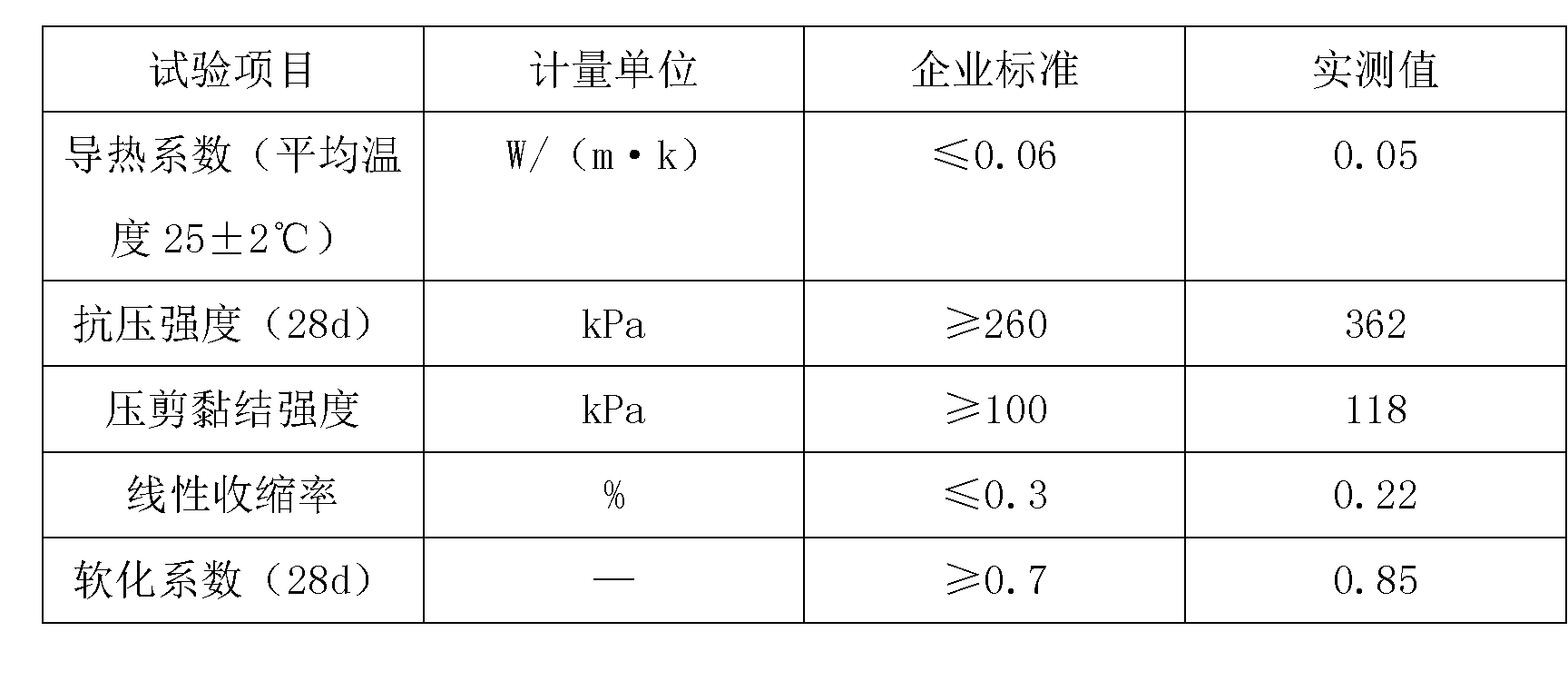

A technology of nano-attapulgite and inorganic thermal insulation mortar, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low strength, poor impact resistance, large thermal conductivity, etc. Compressive strength and impact resistance, improved thermal insulation effect and strength, and excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An inorganic thermal insulation mortar coated with plant ash and modified nano-attapulgite, which is composed of the following raw materials in parts by weight: 52 parts of 42.5-grade ordinary Portland cement, 28 parts of modified carbide slag, 16 parts of plant straw powder, and nano-attapulgite 15 parts, 45 parts of plant ash, 12 parts of starch emulsion, 2 parts of isopropyl distearoyloxyaluminate, 15 parts of vitrified microspheres, 3 parts of redispersible latex powder, 0.8 parts of hydroxyethyl cellulose ether , 0.6 parts of glass fiber, 1.5 parts of polypropylene fiber.

[0014] Wherein, the modified calcium carbide slag is prepared by the following method: adding calcium carbide slag, slag and phosphorus slag into the wet mill according to the ratio of 3:1:1, adding lignin sulfonate equivalent to 15% of the weight of slag powder Calcium sulfate, 8% sodium lauryl ether sulfate and 20% ferrous sulfate, diluted 1.5 times with distilled water, mixed evenly, wet mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com