Purification method of N-methyl pyrrolidone for high polymerization degree polyphenylene sulfide synthesis

A technology of methylpyrrolidone and polyphenylene sulfide, which is applied in the field of purification of N-methylpyrrolidone for the synthesis of polyphenylene sulfide with a high degree of polymerization, can solve problems such as unfavorable polymerization and unfavorable PPS chain growth, and achieve easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

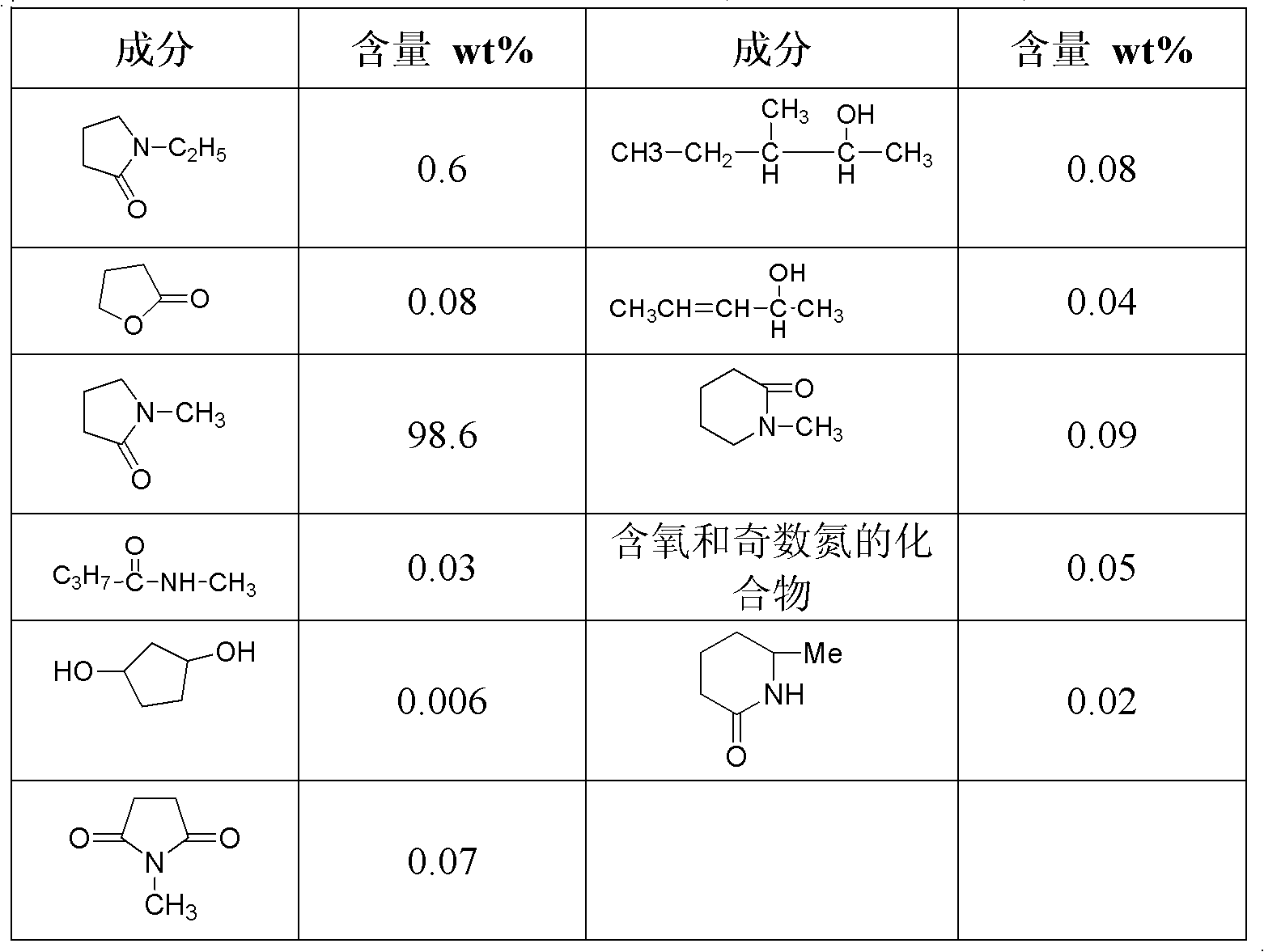

Image

Examples

Embodiment 1

[0029] Add appropriate amount of dehydroxy compound reagent such as Na or K and deaminated compound reagent such as CaCl to NMP 2 Or ZnCl 2 The suspension is reacted at 80-120°C for 5 minutes to 5 hours, and purified NMP is obtained by distillation under reduced pressure, and the performance of NMP is verified by polymerization reaction. The feed is: sodium sulfide / p-dichlorobenzene / NMP / anhydrous trisodium phosphate =1.53mol / 1.5mol / 0.9L / 40g, nitrogen replaces the air in the autoclave, and 0.8MP nitrogen is injected into the autoclave. Reaction at low temperature 160-220°C for 2 hours, reaction at high temperature 250-270°C for 3-4 hours, 250-280°C feeding for 1 hour, 250-280°C p-dichlorobenzene capping for 0.5-1 hour. After the reaction, it was filtered and washed to obtain a white powder. The Mw of the white powder measured by high temperature gel chromatography is 4.2-5.2×10 4 g mol -1 , Molecular distribution index 2.4-3.0.

Embodiment 2

[0031] Add an appropriate amount of anhydrous high-valent metal salt such as AlCl to NMP 3 Or FeCl 3 , The suspension is reacted at a certain temperature of 80-100°C for 5 minutes to 5 hours, and purified NMP is obtained by distillation under reduced pressure. The performance of NMP is verified by polymerization reaction. The feed is: sodium sulfide / p-dichlorobenzene / NMP / trisodium phosphate anhydrous=1.53mol / 1.5mol / 0.9L / 40g, nitrogen replaces the air in the autoclave, and 0.8 is injected into the autoclave MP's nitrogen. React at a low temperature of 160-220°C for 2 hours, at a high temperature of 250-270°C for 3-4 hours, add p-dichlorobenzene at 250-280°C for 1 hour, and block p-dichlorobenzene at 250-280°C for 0.5-1 hours. After the reaction, it was filtered and washed to obtain a white powder. The Mw of white powder measured by high temperature gel chromatography is 3.2-4.1×10 4 g mol -1 , Molecular distribution index 2.2-3.0. The white powder is melted and granulated into...

Embodiment 3

[0033] Add CaH to NMP first 2 After adding TiCl 4 The suspension is reacted at a certain temperature of 80-100°C for 5 minutes to 5 hours, and purified NMP is obtained by distillation under reduced pressure. The performance of NMP is verified by polymerization reaction. The feed is: sodium sulfide / p-dichlorobenzene / NMP / trisodium phosphate anhydrous=1.53mol / 1.5mol / 0.9L / 40g, nitrogen replaces the air in the autoclave, and 0.8 is injected into the autoclave MP's nitrogen. React at a low temperature of 160-220°C for 2 hours, at a high temperature of 250-270°C for 3-4 hours, add p-dichlorobenzene at 250-280°C for 1 hour, and block p-dichlorobenzene at 250-280°C for 0.5-1 hours. After the reaction, it was filtered and washed to obtain a white powder. The white powder Mw measured by high temperature gel chromatography is 3.3-4.8×10 4 g mol -1 , Molecular distribution index 2.0-2.8. The white powder is melted and granulated into milky white particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mw | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com