Purification method of para-dichlorobenzene for high polymerization degree polyphenylene sulfide synthesis

A technology for p-dichlorobenzene and polyphenylene sulfide, which is applied in the field of purifying p-dichlorobenzene for synthesizing high-degree-of-polymerization polyphenylene sulfide, can solve the problems of decreased performance of PPS resin, unfavorable synthesis of PPS resin, and the like, and achieves easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

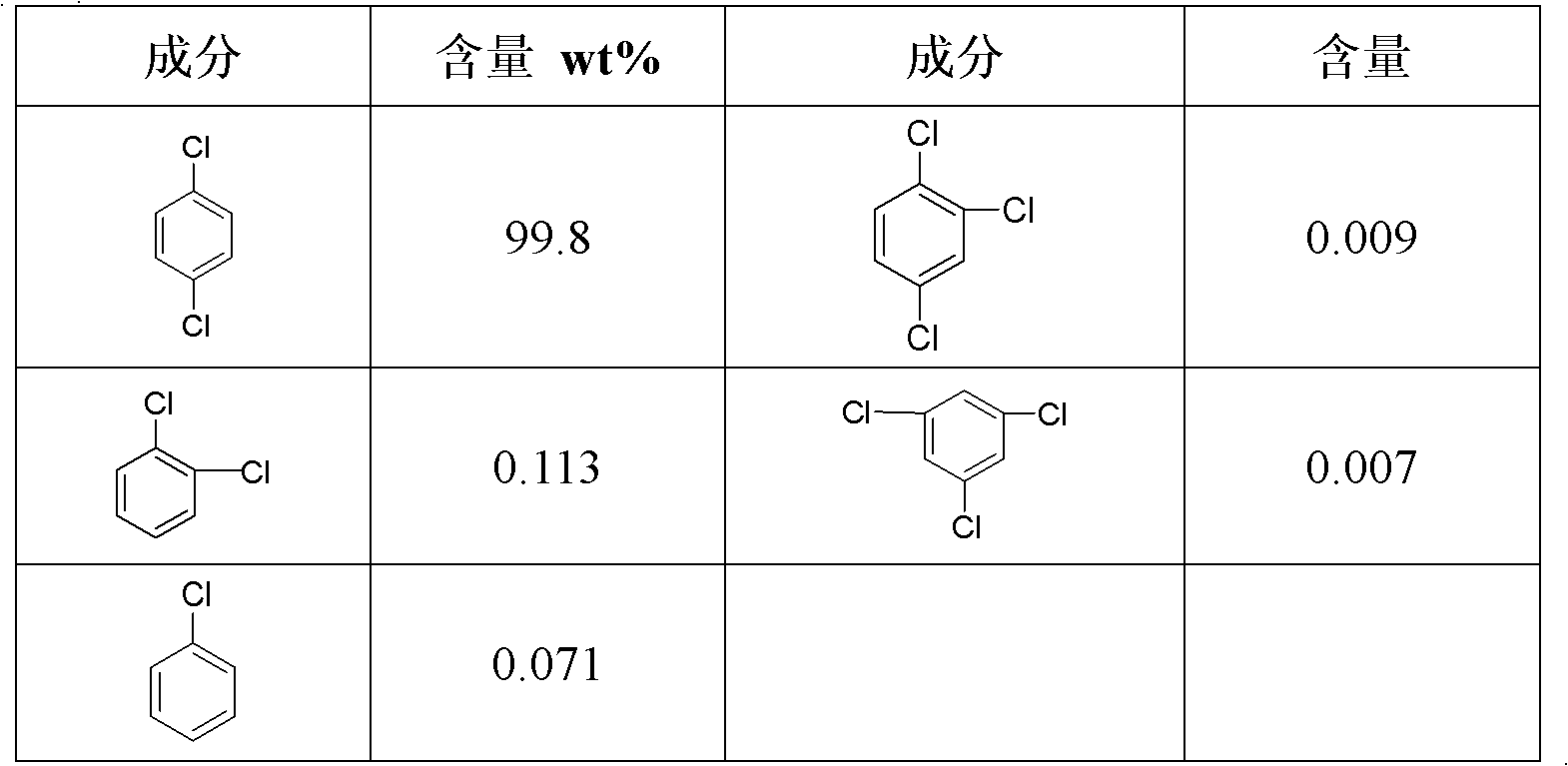

Image

Examples

Embodiment 1

[0032] Melt p-dichlorobenzene, then add 0.2-1% concentrated sulfuric acid or fuming sulfuric acid with moles of p-dichlorobenzene to the molten p-dichlorobenzene, sulfonate at 40-100°C for 10-30 minutes, then distill off monochlorobenzene and part of o-dichlorobenzene to obtain high-purity p-dichlorobenzene A1 suitable for the synthesis of polymer PPS resin.

Embodiment 2

[0034] Melt p-dichlorobenzene, then add 0.2-1% concentrated nitric acid with moles of p-dichlorobenzene to the molten p-dichlorobenzene, nitrate at 80-120°C for 10-30 minutes, distill off monochlorobenzene and some ortho-dichlorobenzene to obtain high-purity p-dichlorobenzene A2 suitable for the synthesis of polymer PPS resins.

Embodiment 3

[0036] Melt p-dichlorobenzene, then add 0.2-1% concentrated nitric acid and an appropriate amount of concentrated sulfuric acid to the p-dichlorobenzene molten liquid, nitrate at 80-120°C for 10-30 minutes, and distill off a Chlorobenzene and part of ortho-dichlorobenzene to obtain high-purity p-dichlorobenzene A3 suitable for the synthesis of polymer PPS resin.

[0037] The purification effect was verified by the performance characterization after the synthesis of PPS.

[0038] The synthesis method is: add 1.5mol of untreated industrial grade p-dichlorobenzene A0 and purified p-dichlorobenzene A1, A2, A3 into the kettle, add 1.53mol of sodium sulfide, 0.9L of N-methylpyrrolidone, anhydrous Trisodium phosphate 40g, the air in the nitrogen replacement still, and inject the nitrogen of 0.8MP in the autoclave. Reaction at low temperature 160-220°C for 2 hours, high temperature at 250-280°C for 3-4 hours, continuous addition of p-dichlorobenzene at 250-280°C for 0.5-1 hour, addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com