Integration synthesis process for polyurethane prepolymer synthesis and elastic body pouring and casting machine

A polyurethane prepolymer and synthetic elastomer technology, which is applied in the integrated synthetic process of elastomer casting and polyurethane prepolymer synthesis, can solve the problem of low convection velocity of heat-conducting medium, inconvenient frequent opening and closing of valve feeding, discharging and tank Loading operation, unable to carry out sufficient stirring, mixing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

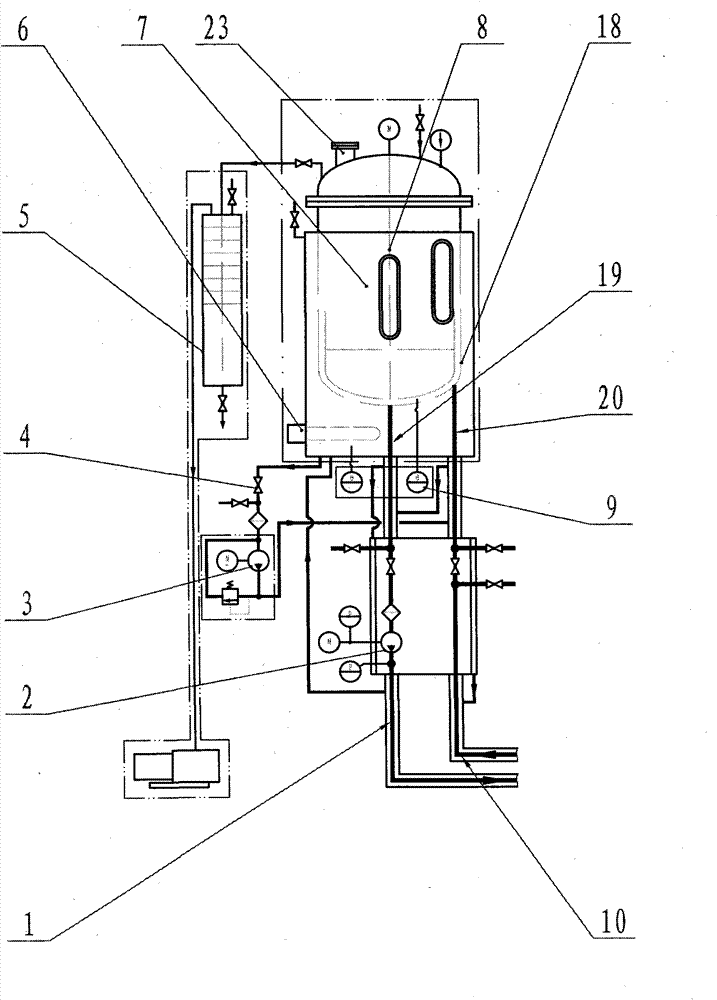

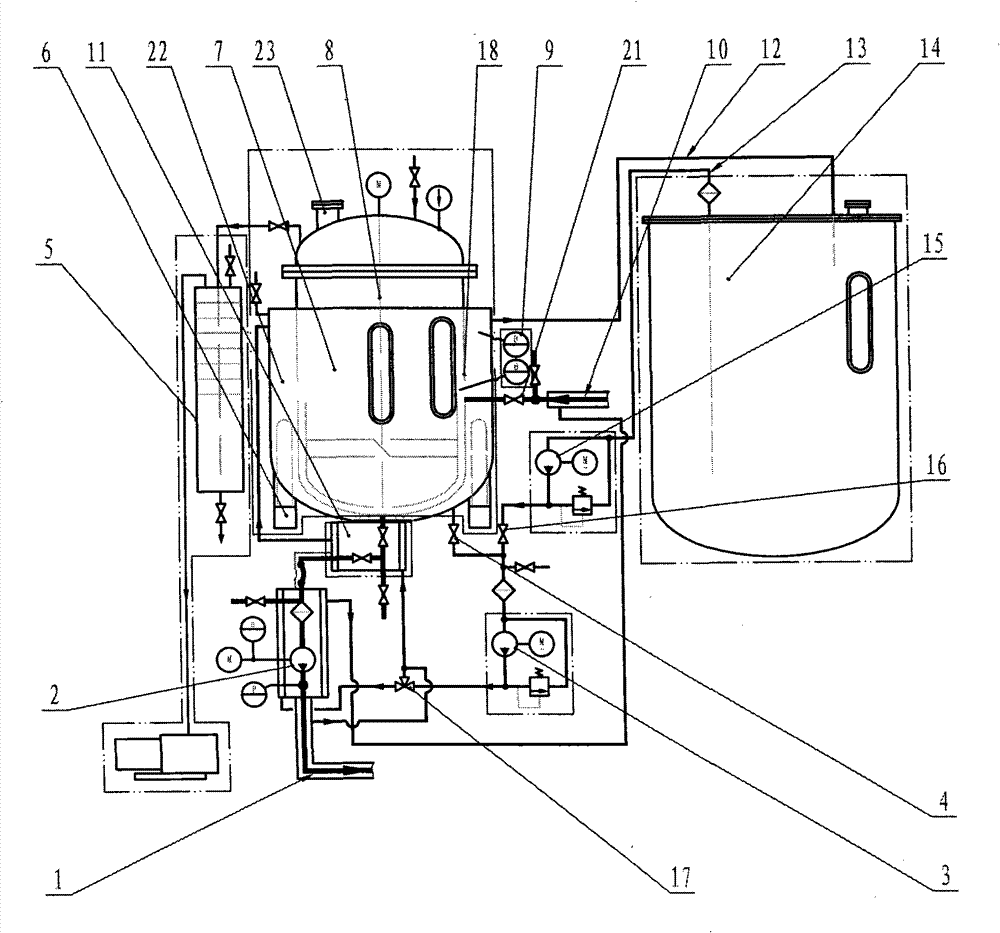

[0047] Embodiment 1: adopt two-step method (prepolymer method) technique, use pouring machine of the present invention, be the prepolymer synthesized by the ethylene glycol propylene glycol fat of 1000 and toluene diisocyanate with number average molecular weight, and 3,3′-dichloro-4,4′-diaminodiphenylmethane undergoes cross-linking chain extension reaction to produce castable polyurethane prepolymer synthesis and elastomer products with a hardness of Shore A95°±2°

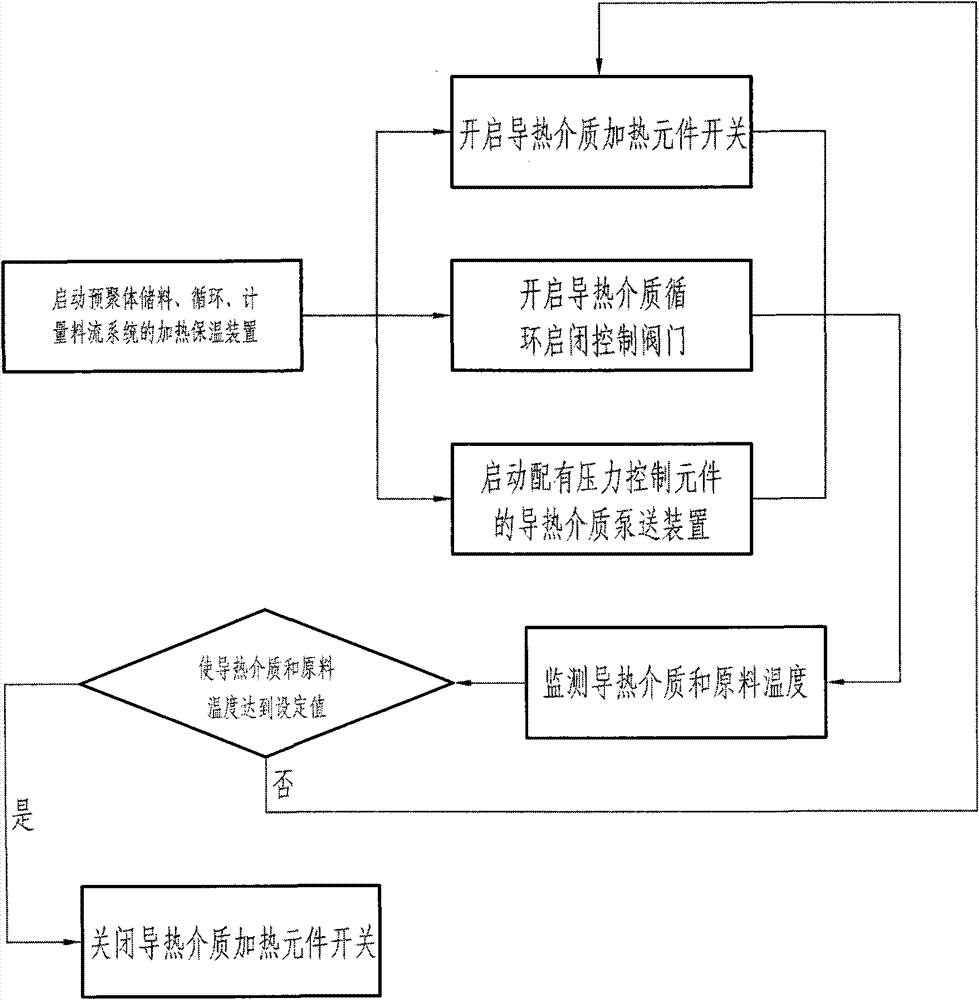

[0048] Adjust the working state of the pouring machine to the state where the prepolymer reaction tank (which also has the function of storing material) is in an independent working state and is heated and kept warm, and the heat-conducting medium heating element 6 is connected, and the prepolymer storage, When the reaction tank 7 is in the independent working state and the pouring machine is in the circulation, metering and pouring states, the heat transfer medium circulation path is switched to the prepolymer sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com