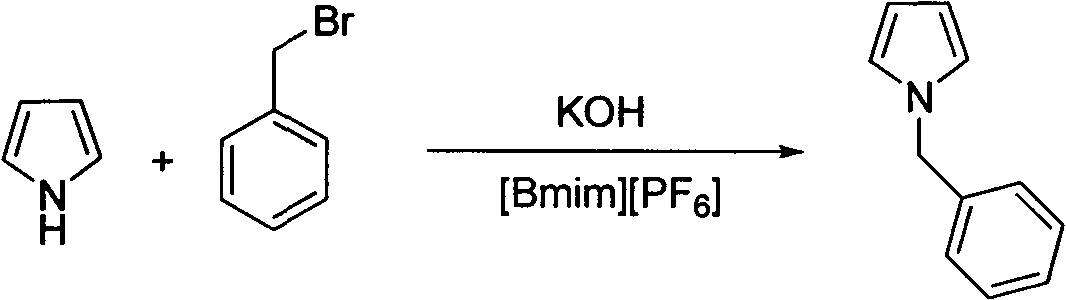

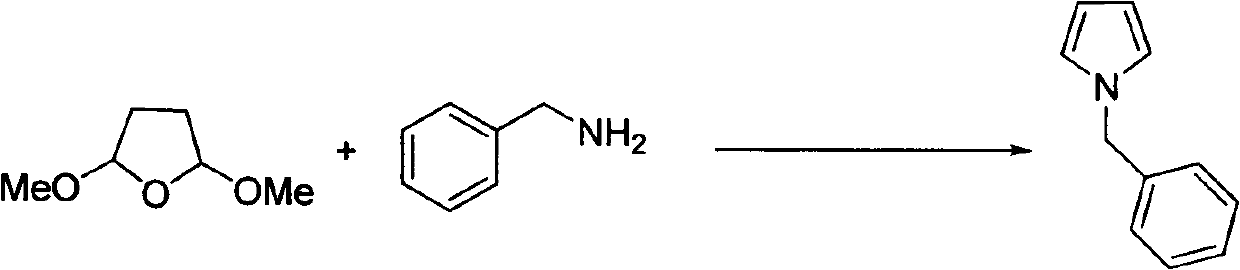

Preparation method of N-substituted-1H-pyrrole

A technology of C-140 and aromatic heterocycles, which is applied in the field of preparation of pyrrole derivatives, and can solve problems such as side reactions, unstable raw materials, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 N-benzyl-1H-pyrrole

[0047]

[0048] FeSO 4 .7H 2 O (0.021g, 0.15mmol), N,N-dimethylethylenediamine (0.027g, 0.3mmol) were suspended in 10ml of toluene, stirred at room temperature for 10min, then added 4-(benzoyloxy)-1 -benzyl-pyrrolidine-2-carboxylic acid (0.33g, 1mmol), di-tert-butyl peroxide (0.2g, 1.4mmol), reflux reaction overnight, the reaction solution was decompressed to remove the solvent, silica gel column chromatography (washing Off-line (petroleum ether / ethyl acetate = 10:1 (v / v)) to obtain 0.10 g of N-benzyl-1H-pyrrole, a colorless liquid, with a yield of 64%; 1 HNMR (400MHz, CDCl 3 )δppm5.18(s, 2H), 6.36(t, J=2.01, 2.01Hz, 2H), 6.84(t, J=1.99, 1.99Hz, 2H), 7.26(d, J=7.08Hz, 2H), 7.45(m, 3H); 13 C NMR (101MHz, CDC1 3)δppm 53.43, 108.68, 121.30, 127.14, 127.77, 128.86, 138.371; MS, m / z (relative intensity): 157.1 (69.8), 91.1 (100), 158.1 (7.7), 156.1 (8.3), 92.1 (6.5) .

Embodiment 2

[0049] The preparation of embodiment 2 N-benzyl-1H-pyrrole

[0050]

[0051] Except replacing FeSO with CuBr (0.022g, 0.15mmol) 4 .7H 2 Except for O (0.021g, 0.15mmol), the others were the same as in Example 1 to obtain 0.10g of N-benzyl-1H-pyrrole, a colorless liquid, with a yield of 62%; 1 H NMR (400MHz, CDC1 3 )δppm5.18(s, 2H), 6.36(t, J=2.01, 2.01Hz, 2H), 6.84(t, J=1.99, 1.99Hz, 2H), 7.26(d, J=7.08Hz, 2H), 7.45(m, 3H); 13 C NMR (101MHz, CDC1 3 )δppm 53.43, 108.68, 121.30, 127.14, 127.77, 128.86, 138.371; MS, m / z (relative intensity): 157.1 (69.8), 91.1 (100), 158.1, 7.7), 156.1 (8.3), 92.1 (6.5) .

Embodiment 3

[0052] Example 3 Preparation of N-(4-trifluoromethyl-benzyl)-1H-pyrrole

[0053]

[0054] Except that 4-(benzoyloxy)-1-(4-(trifluoromethyl)-benzyl)pyrrolidine-2-carboxylic acid (0.39 g, 1 mmol) was used instead of 4-(benzoyloxy) -1-(4-benzyl)pyrrolidine-2-carboxylic acid (0.33g, 1mmol), the others are the same as in Example 1 to obtain N-(4-trifluoromethyl-benzyl)-1H-pyrrole 0.14 g, yellow liquid, yield 63%; 1 NMR (400MHz, CDCl 3 )δppm 5.19(s, 2H), 6.31(s, 2H), 6.76(s, 2H), 7.25(d, J=7.96Hz, 2H), 7.64(d, J=7.97Hz, 2H); 13 C NMR (101MHz, CDC1 3 ) δppm 52.80, 109.10, 121.24, 125.74 (q, J=3.77, 3.75, 3.75Hz, 1C), 127.10, 142.43; ESI for [M+H]: calculated, 226.0844; found, 226.0843.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com