Benzoxazine resin/ionic liquid composition

A technology of resin composition and benzoxazine, which is applied in the field of resin composition, can solve the problems of reducing the curing temperature of benzoxazine, lowering the curing temperature, not paying attention to benzoxazine/ionic liquid composition, etc., and achieving Lower curing temperature, easy curing, and excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0102] Preparation method of benzoxazine resin / ionic liquid composition

[0103] According to another aspect of the present invention, there is provided the preparation of a benzoxazine resin / ionic liquid composition by mixing a benzoxazine resin with an ionic liquid.

[0104] As a mixing method, a mixing method well known to those skilled in the art can be used, such as mechanical stirring mixing, solution mixing, melt mixing, assisted ultrasonic dispersion, high-speed stirring and the like.

[0105] Thermosetting resin resin composition

[0106] According to yet another aspect of the present invention, there is provided a thermosetting resin composition comprising: the benzoxazine resin / ionic liquid composition according to the present invention, and other thermosetting resins and / or fillers.

[0107] As the other thermosetting resin, benzoxazine resins such as N-alkylbenzoxazine resin, N-phenylbenzoxazine resin, N-alicyclic benzoxazine resin, N-allyl can be used Benzo...

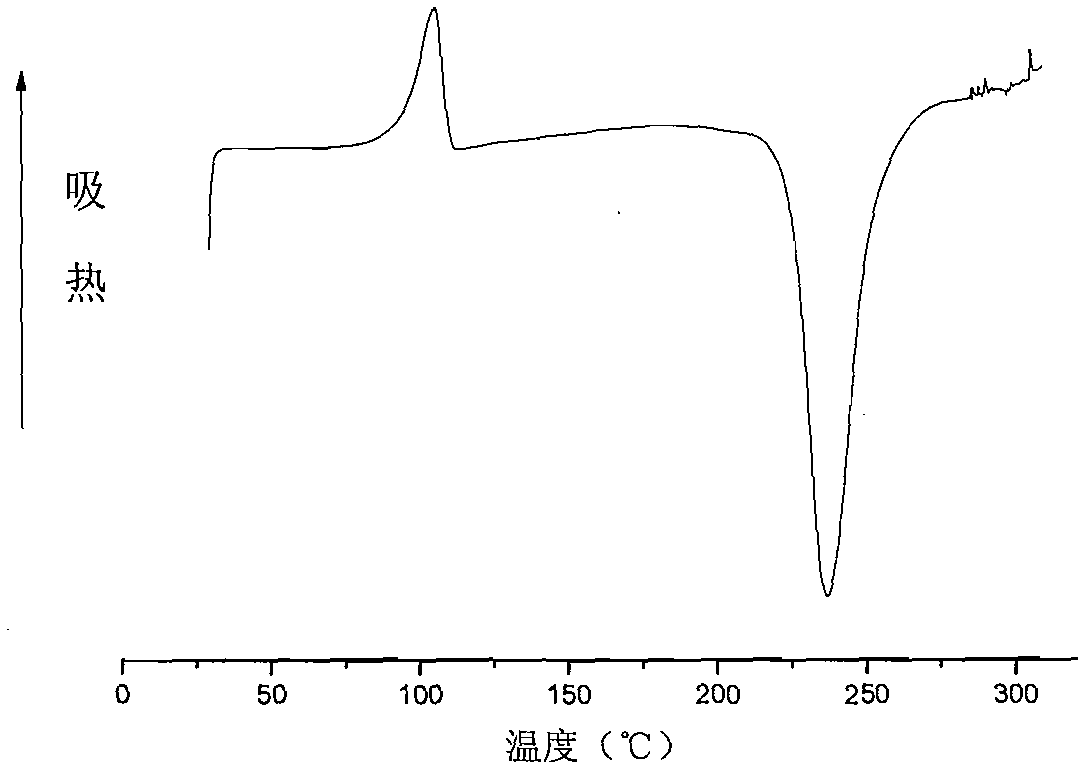

Embodiment 1

[0113] With the ratio (mass ratio) of 0.1: 99.9, prepare N-butylpyridine chloride ionic liquid and bisphenol A aniline-type benzoxazine resin (preparation method: successively in a 1000ml there-necked flask equipped with a condenser, stirring and a thermometer) Add solvent toluene 500ml, add bisphenol A 114g (0.5mol), aniline 120ml (1mol) in turn, slowly add paraformaldehyde 60g (2mol) under strong stirring in an ice-water bath, and stir vigorously at room temperature to mix the reactants uniformly, Put it in an oil bath at 105°C for 4 hours. After the reaction, add 1 mol / L lye, stir and mix, then pour it into a separatory funnel to separate the product, continue to wash with lye, and finally wash it with deionized water until it becomes neutral. Put it into a porcelain plate and dry it in a vacuum at 60°C for 24 hours to obtain a pale yellow solid, that is, a composition of bisphenol A aniline benzoxazine. The oxazine is dissolved in chloroform, ultrasonically dispersed for 1...

Embodiment 2

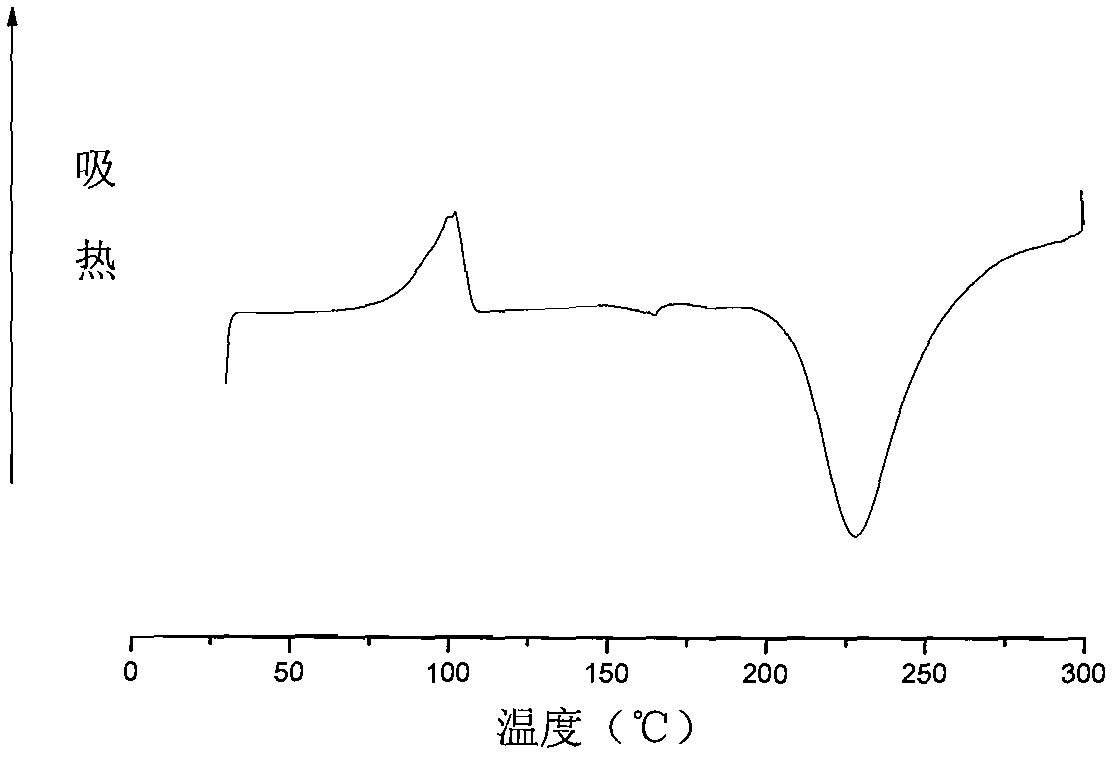

[0116] In the same method as in Example 1, the composition of N-methyl-N-butylpyrrolidine chloride ionic liquid and bisphenol A aniline benzoxazine resin was prepared in a ratio (mass ratio) of 0.1:99.9 .

[0117] The composition is tested by DSC, and the obtained DSC curve is shown in figure 2 As shown in (please supplement the complete DSC curve), the cure initiation temperature was measured to be 206°C, the cure peak temperature to be 229°C, and the cure end temperature to be 256°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curing start temperature | aaaaa | aaaaa |

| Curing peak temperature | aaaaa | aaaaa |

| Curing start temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com