Medical low-temperature resistant low-mobility polyvinyl chloride calendered film material and preparation method thereof

A polyvinyl chloride and calendering film technology, which is applied in the field of low-temperature-resistant low-migration polyvinyl chloride medical calendering film materials and its preparation, can solve the problems of high-risk groups and adverse effects, and achieve surface roughness, high oxygen permeability, Reduce precipitation and make the finished product simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

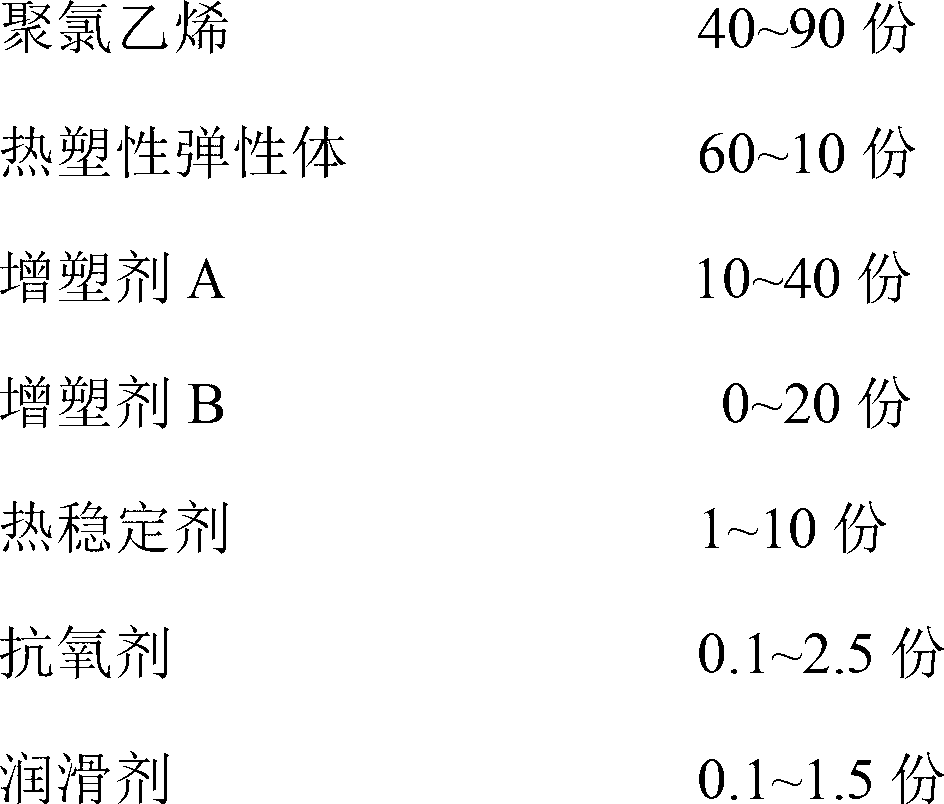

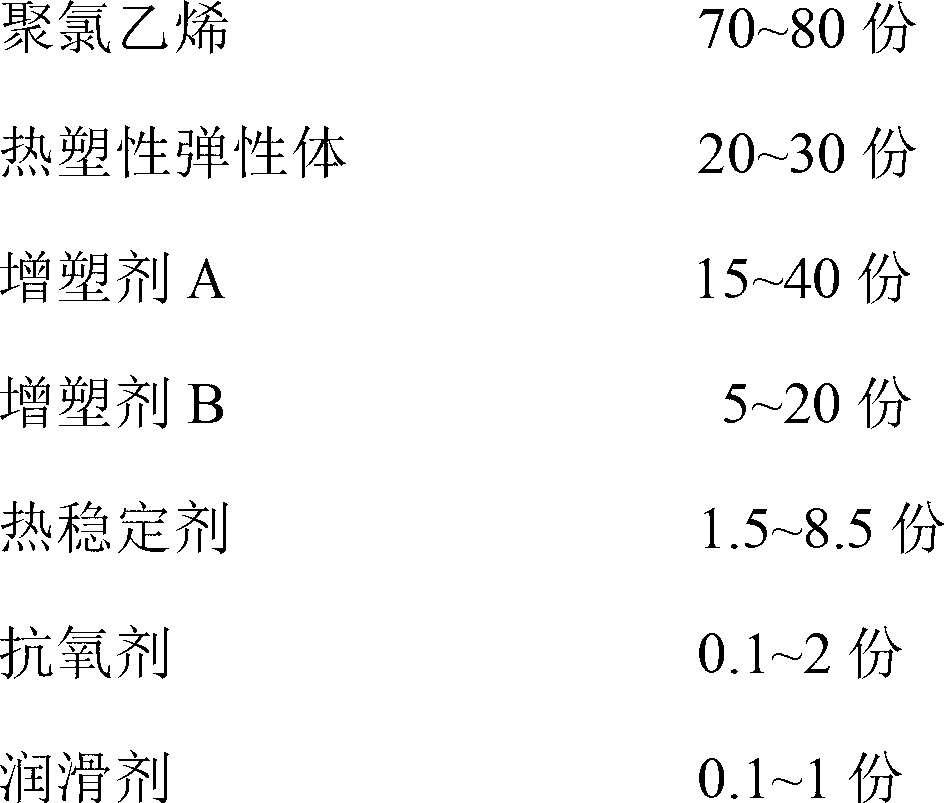

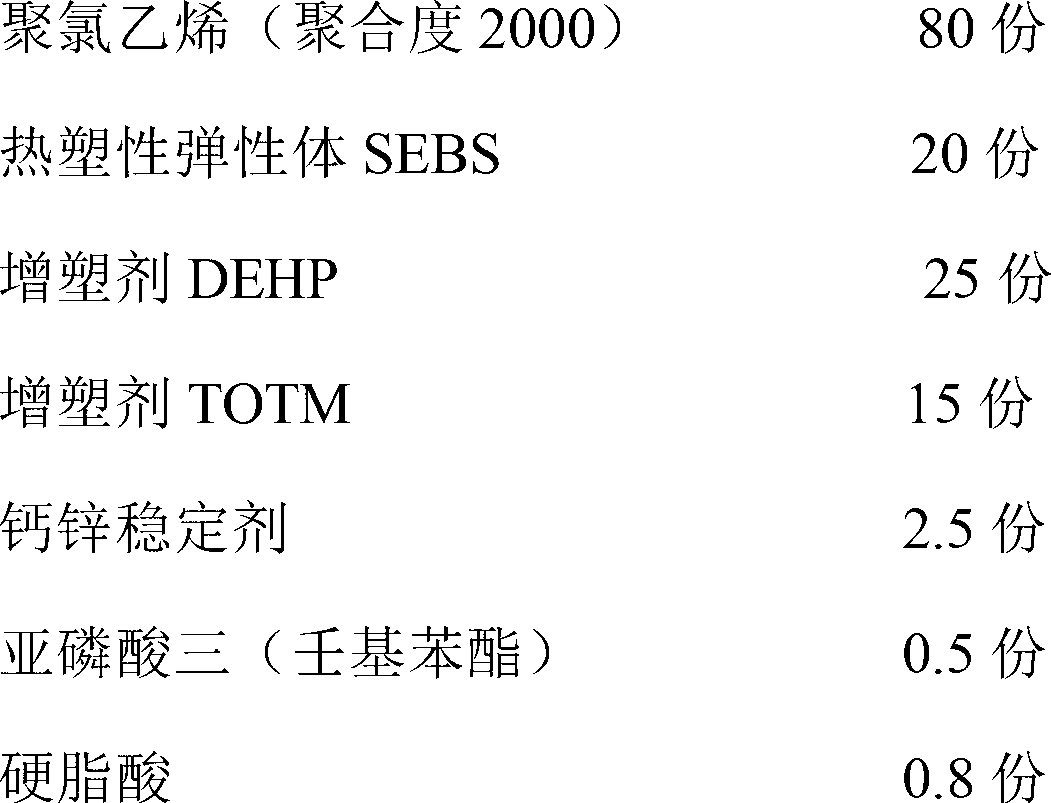

[0037] formula:

[0038]

[0039] Preparation:

[0040] 1. Preparation of premix

[0041]

[0042] Preheat the kneader to 40°C±2°C, add PVC resin, calcium zinc stabilizer and tris(nonylphenyl phosphite) according to the weight ratio, and add plasticizer DEHP and plasticizer when the temperature rises to 70°C±1°C Plastic agent TOTM, after DEHP and TOTM are fully absorbed, add stearic acid at 95°C±2°C, mix, when the temperature reaches 125°C±2°C, discharge the mixture out of the high-speed kneader to obtain a premix.

[0043] 2. Preparation of extrudate

[0044] formula:

[0045] Premix: 80 parts

[0046] Thermoplastic Elastomer SEBS: 20 parts

[0047] The double-stage twin-screw extruder is an extruder with a diameter of 75mm for the upper-stage twin-screw and a diameter of 180mm for the lower-stage single-screw. The length-to-diameter ratio of the extruder is 1:30, and the compression ratio is 1:3.0. The first feeding port of the extruder is at extruder 4D, and the...

Embodiment 2

[0057] formula:

[0058]

[0059] Preparation:

[0060] 1. Preparation of premix

[0061]

[0062] The preferred premixing process of the present invention: preheat the high-speed kneader to 40°C±2°C, add PVC resin, heat stabilizer and antioxidant according to the weight ratio, and add plasticizer DEHP when the temperature rises to 70°C±1°C And plasticizer DOA, after DEHP and DOA are fully absorbed, add lubricant at 95°C±5°C, mix, when the temperature reaches 130°C±1°C, discharge the mixture from the high-speed kneader to obtain a premix.

[0063] 2. Preparation of extrudate

[0064] Preferred formulation:

[0065] Premix: 70 parts

[0066] Thermoplastic elastomer CPE 30 parts

[0067] Thermoplastic elastomer POE 10 parts

[0068] Others are the same as embodiment 1.

[0069] Table 1 shows the performance test of the calendered film prepared by the aforementioned process.

[0070] Table 1 Performance index of medical polyvinyl chloride calendered film

[0071] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com