Nanometre modified high self-cleaning solar heat reflecting paint and preparation method thereof

A nano-modified, reflective coating technology, applied in reflective/signal coatings, antifouling/underwater coatings, coatings, etc., can solve difficult cleaning, difficulty in tall buildings, and reduced ability to reflect sunlight on the surface, etc. problem, to achieve the effect of good anti-ultraviolet performance, reduce cleaning work, and improve reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

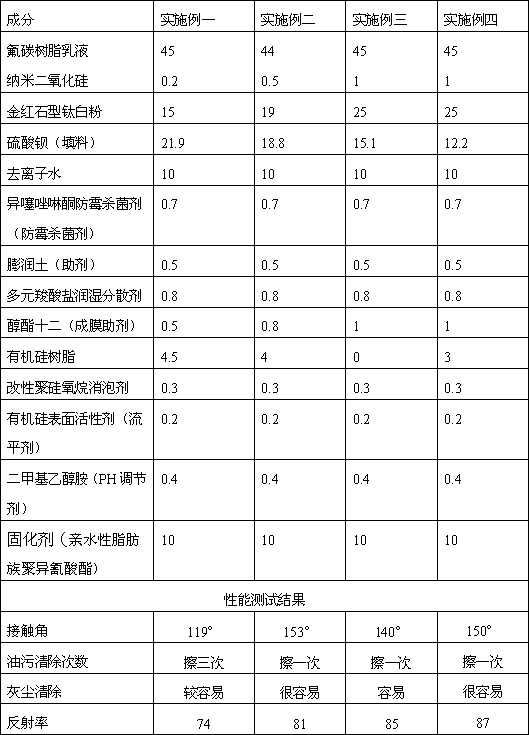

[0013] Embodiments of the present invention: (each component unit is kg)

[0014]

[0015] First add deionized water to the mixing tank, then add wetting and dispersing agent for stirring, then add nano-silica, rutile titanium dioxide, and filler in sequence at a speed of 400-600r / min, stir for 10-15 minutes, and then Add defoamers, additives, anti-mold and fungicides, disperse at a high speed of 800-1200r / min for 20-30 minutes, and then use a sand mill to grind the fineness to less than 10 microns to form a color paste, and then add fluorocarbon Resin emulsion, film-forming aid, leveling agent, silicone resin and PH regulator, stirred evenly, and filtered.

[0016] When the present invention is used, add curing agent and stir evenly, after adding deionized water, spray, brush, roll coat the surface of the object to be coated, and dry for 24 hours.

[0017] The fluorocarbon resin used in the invention has uniform and excellent outdoor durability, good anti-ultraviolet perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com