Recycling method of zinc hypoxide

A technology of secondary zinc oxide and zinc oxide, which is used in the improvement of process efficiency, photography process, instruments, etc., can solve the problems of difficult to master process conditions, increased production costs, and poor production management, and achieves good cobalt effect and processing capacity. big, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

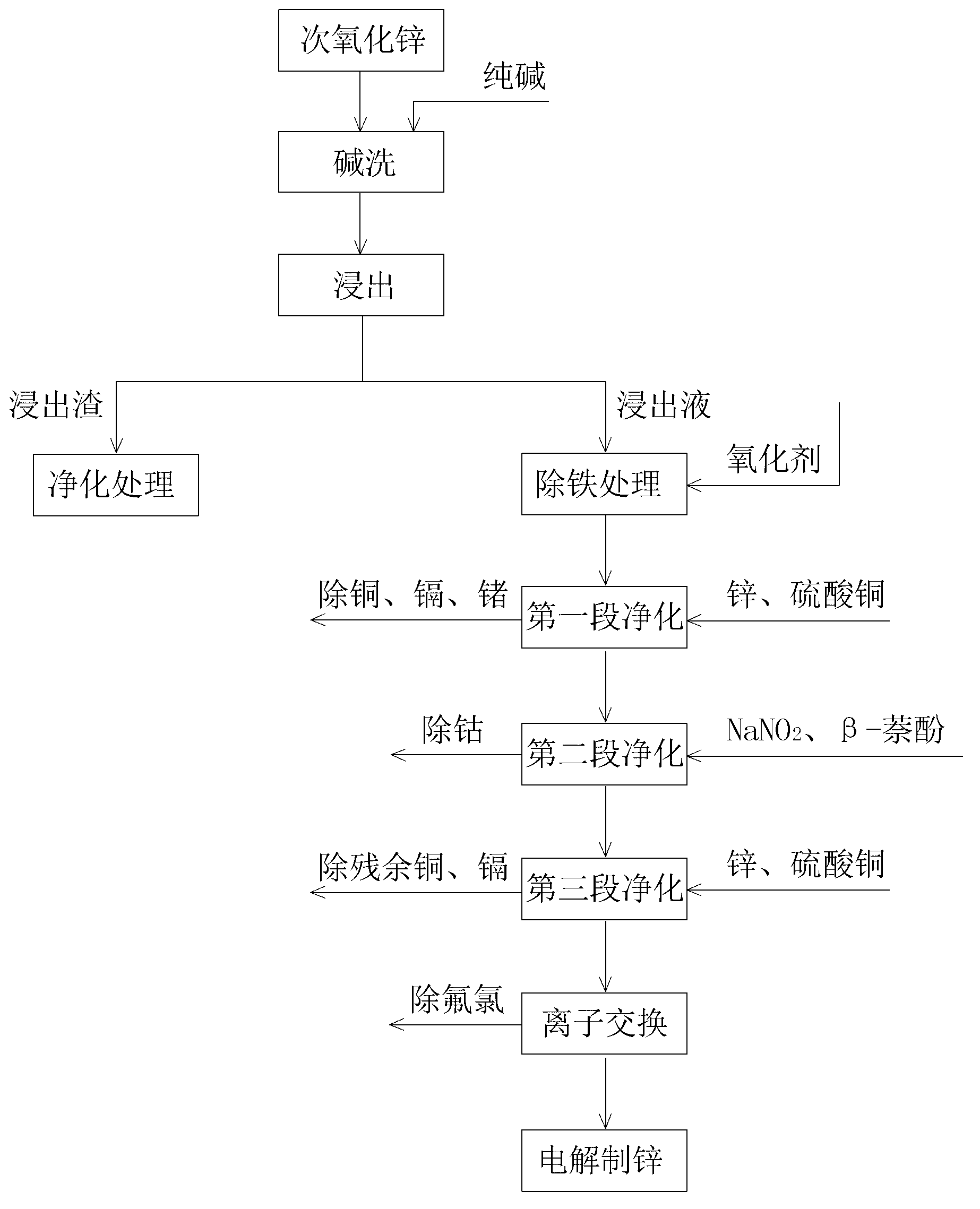

[0037] combine figure 1 , a method for recycling secondary zinc oxide, comprising the following steps:

[0038] A, carry out alkali washing with secondary zinc oxide with soda ash solution, obtain zinc carbonate;

[0039] B, leaching the zinc carbonate in the step a, obtaining leachate and leach slag after separation;

[0040] c. Adding an oxidizing agent to the leaching solution for iron removal treatment, and obtaining a purified solution after separation;

[0041] d. Perform three-stage purification treatment on the purification solution obtained in step c, remove cadmium, copper, germanium, and cobalt impurities in the solution, and obtain a deep purification solution after separation;

[0042] E, carrying out ion-exchange treatment to the deeply purified solution obtained in step d, removing fluorine and chlorine in the solution;

[0043] f. Electrolyzing the solution obtained after ion exchange to precipitate zinc.

[0044] In the recycling method of secondary zinc oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com