Factory-made orthotropic steel plate and composite combined deck structure

An orthotropic, composite material technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as fatigue cracking of steel bridge deck structures, damage to asphalt mixture pavement, safety hazards, etc., and achieve stable high temperature stability. and low temperature crack resistance, high stiffness, anti-cracking effect of pavement layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

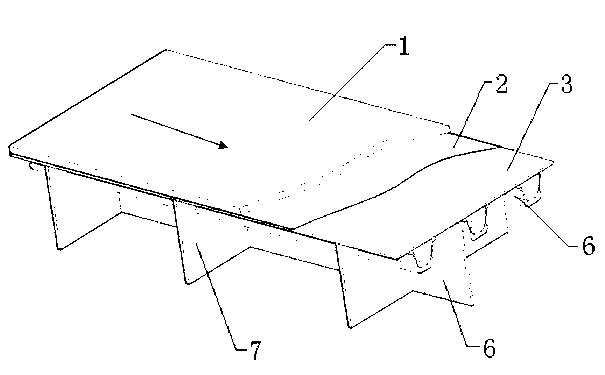

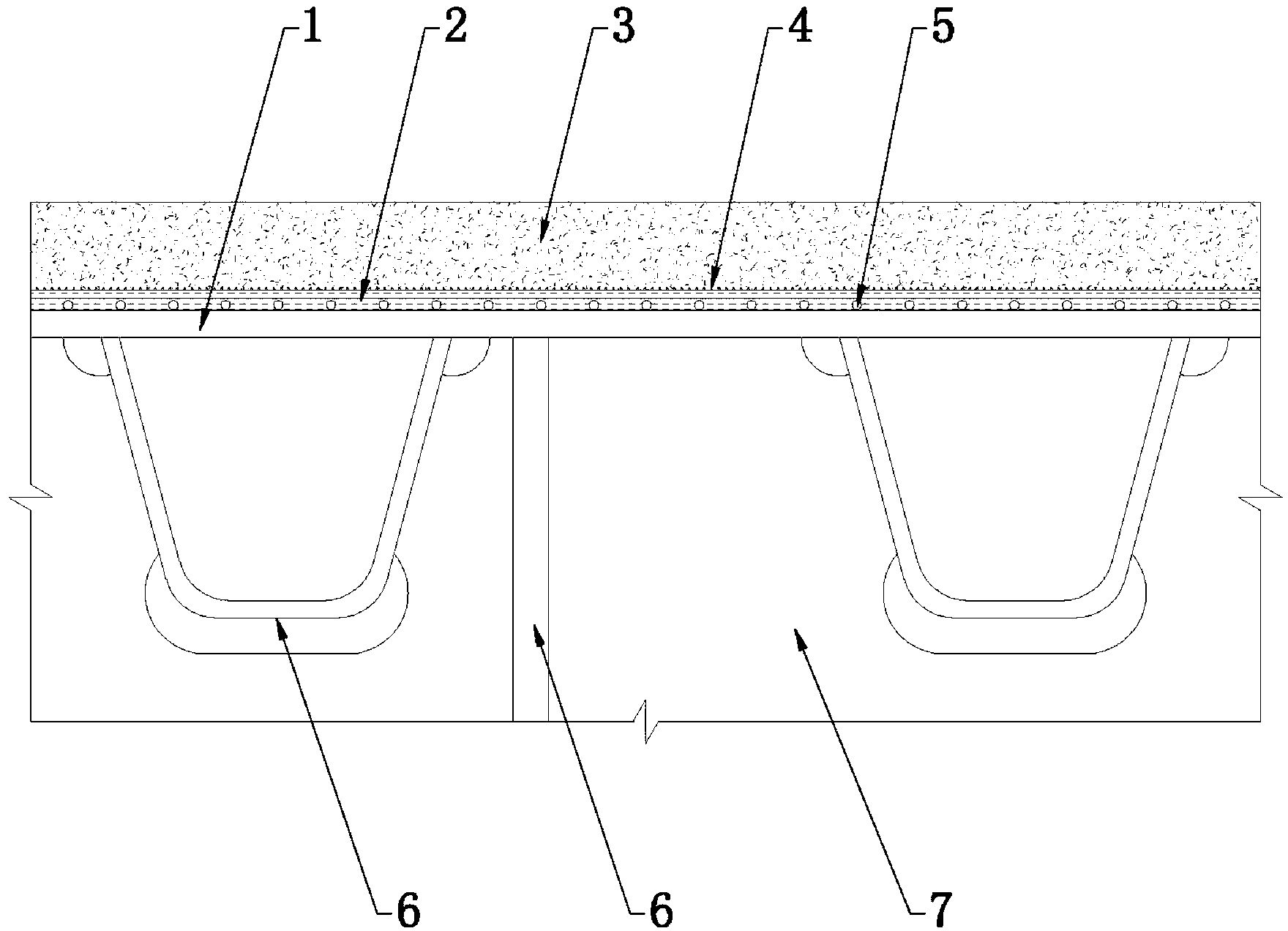

[0026] The factory prefabricated orthotropic steel plate-composite material composite bridge deck structure of the present invention comprises orthotropic steel plate 1, and the orthotropic steel plate 1 is provided with rib shear key 5, and is arranged on the upper surface of orthotropic steel plate 1 Composite material layer 2 with a thickness of 5 mm. The composite material layer 2 is made of 8 layers of biaxial glass fiber cloth and vinyl resin cured. The top layer of glass fiber cloth is a rough surface layer 4 composed of looped fabric. Import process preparation, and finally pour a layer of wear layer 3 made of asphalt mixture with a thickness of 4cm.

Embodiment 2

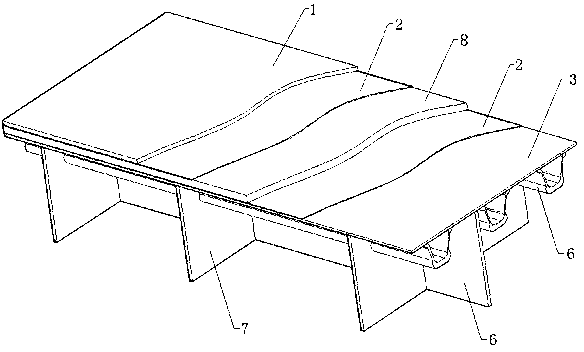

[0028] The factory prefabricated orthotropic steel plate-composite material composite bridge deck structure of the present invention comprises orthotropic steel plate 1, and the orthotropic steel plate 1 is provided with rib shear key 5, and is arranged on the upper surface of orthotropic steel plate 1 The interior of the layer is filled with a composite material layer 2 of a core material 8 made of paulownia wood with a thickness of 5 cm. On both sides of the core material 8, 5 layers of biaxial glass fiber cloth with a thickness of 3 mm and a composite material cured with vinyl resin are laid. The material is to form a composite material layer 2, and the upper layer of glass fiber cloth on the composite material layer 2 is a rough surface layer 4 composed of a loop fabric, which is prepared by a vacuum introduction process, and finally a layer of asphalt mixture with a thickness of 3 cm is poured. wear layer 3.

Embodiment 3

[0030] The factory prefabricated orthotropic steel plate-composite material composite bridge deck structure of the present invention comprises orthotropic steel plate 1, and the orthotropic steel plate 1 is provided with rib shear key 5, and is arranged on the upper surface of orthotropic steel plate 1 The interior of the layer is filled with a composite material layer 2 of a core material 3 made of paulownia wood with a thickness of 5 cm. The composite material webs 7 are regularly arranged along the thickness direction of the core material 3, and the webs 7 are perpendicular to the orthotropic steel plate 1. Both sides of 8 are laid with 5 layers of composite material made of four-axis basalt fiber cloth and epoxy resin cured to form the composite material layer 2, and the upper layer of glass fiber cloth on the composite material layer 2 is a rough fabric made of looped fabric. The surface layer 4 is prepared by a vacuum introduction process, and finally a layer of concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com