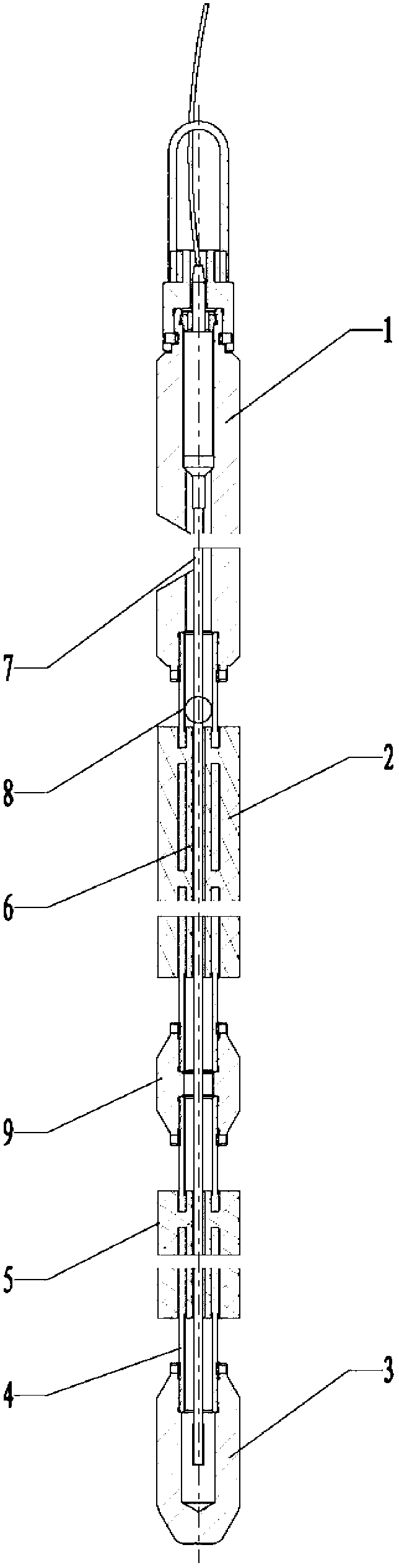

Scattered object fracturing bomb device

A fracturing bomb and drop-off technology, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., to reduce the source of residue, avoid falling objects in the well, and improve the pressure bearing level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Following the technical solution of the present invention, the outer charge column 5 , the inner charge column 6 and the central tube 4 in the debris fracturing bomb device of this embodiment are solidified together through a casting process.

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the end of the detonating cord 7 at the tail 3 is wrapped and sealed with a high temperature and high pressure resistant self-adhesive tape, so as to prevent the well fluid from infiltrating into the detonating cord 7 and affecting detonation.

Embodiment 3

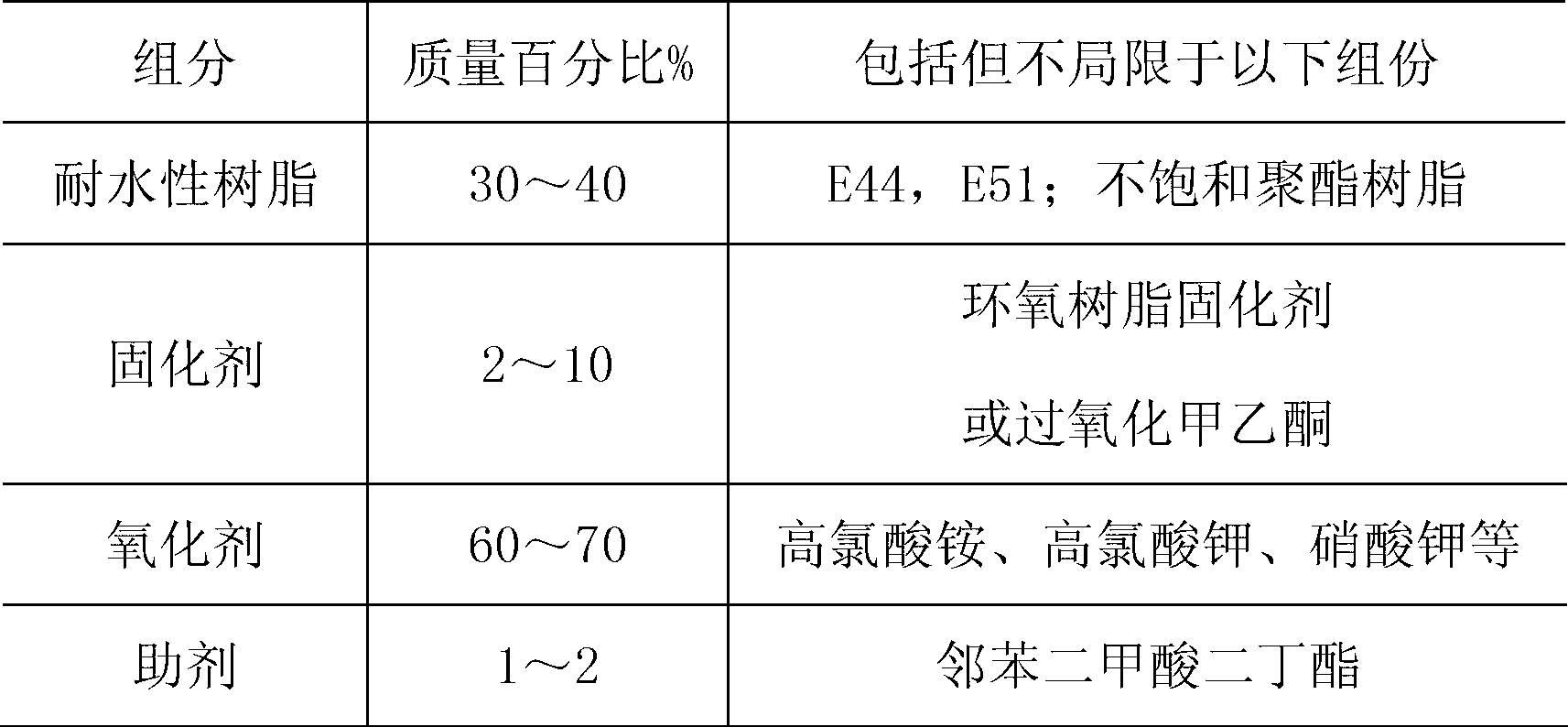

[0033] The difference between this embodiment and implementation 2 is that the outer charge column 5 and the inner charge column 6 are both intrinsically water-resistant composite powder columns, and the formula of the intrinsically water-resistant composite powder is shown in Table 1 above.

[0034] If the composite gunpowder is not inherently water-resistant, all surfaces of the grain can be covered by a coating process. The main coating material can be selected from epoxy resin, unsaturated polyester resin, polyurethane, fluororubber and other polymer materials through the grain. Dip coating, brush coating or mold coating, the coating thickness is 0.1mm ~ 1mm, the best is 0.5mm.

[0035] During construction, a certain length of fracturing bomb string device is firstly transmitted to a predetermined layer with a cable, and the detonator in the ignition assembly 1 is detonated through the cable, and the detonator detonates the detonating cord 7 in the central screen, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com