Hydrogen eliminating test system with safety protection function

A safety protection and test system technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as complex processing, large thermal resistance, and prone to explosion risks, and achieve the effect of improving safety performance and preventing explosion hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

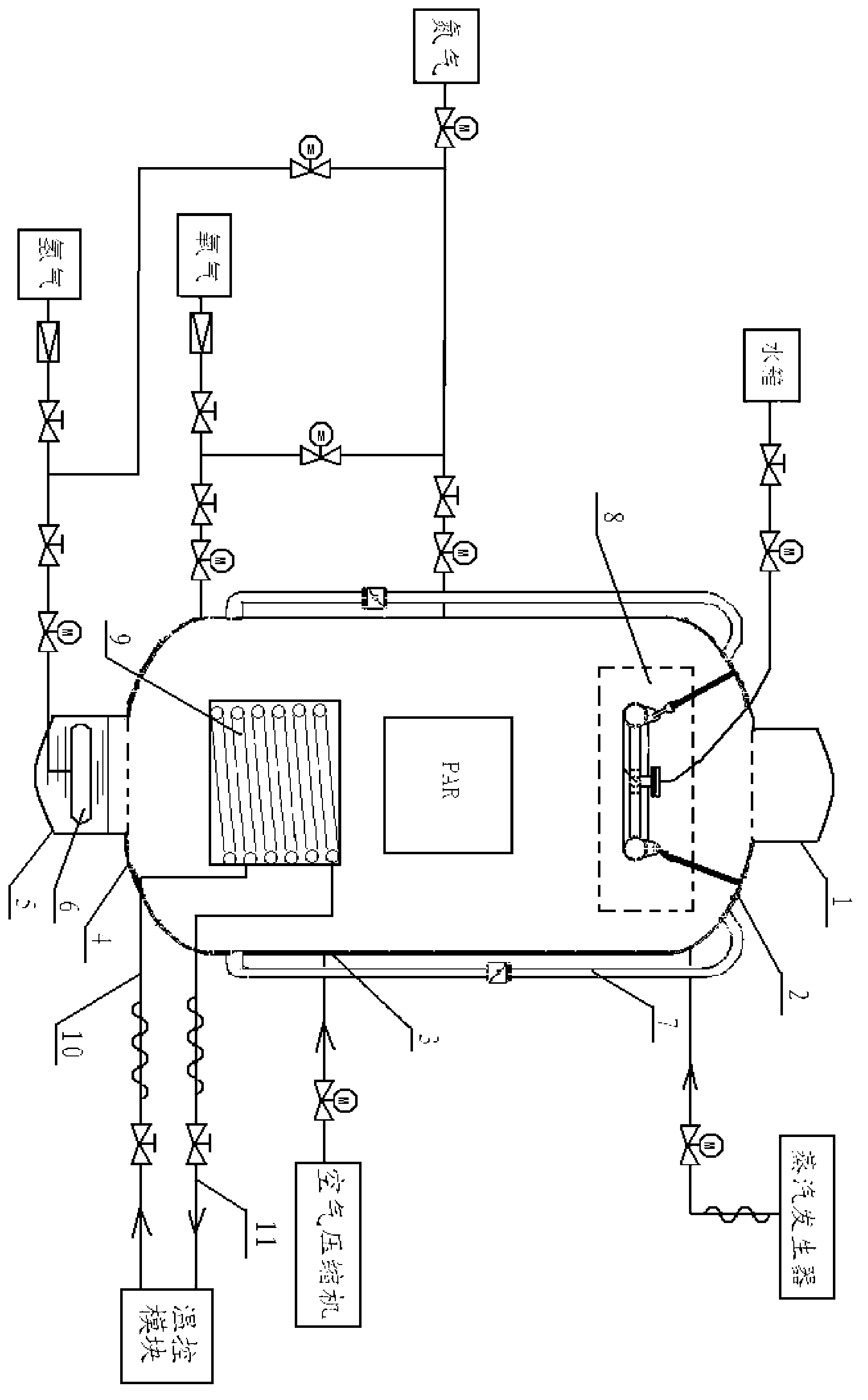

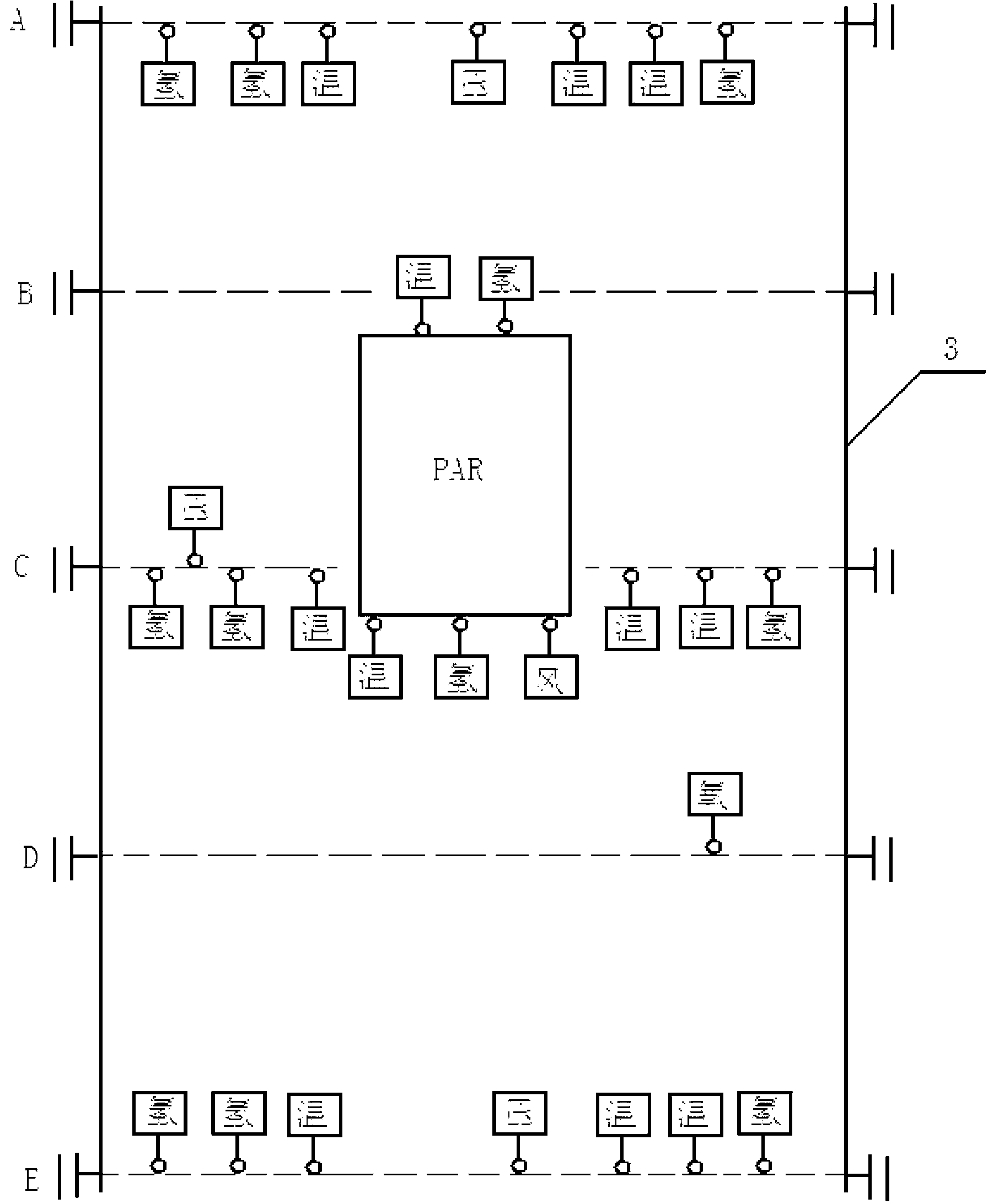

[0038] In order to truly reflect the working conditions of the nuclear power plant site, this embodiment provides a complete machine test system for passive hydrogen recombiner (PAR), such as figure 1 shown. In this test device, the PAR uses a 1:1 prototype with the site for the whole machine test, and simultaneously simulates the environment of high temperature, high pressure and high humidity in the containment of the nuclear power plant, so as to truly reflect the hydrogen depletion performance of the PAR on the site of the nuclear power plant.

[0039] The PAR complete machine test system of this embodiment includes a tank body, a hydrogen supply device, an oxygen supply device, a nitrogen supply device, a cooling device, a detection device, a temperature control device, an air compressor, a steam generator, a data acquisition control module, and a saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com