Method and device for preparing silty soil triaxial-test test sample

A triaxial test and silt technology, applied in the field of silt, can solve the problems of difficult silt sample preparation, insufficient resistance to damage, and different test results, and achieve easy-to-master technical means, high reproducibility, and reliability high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

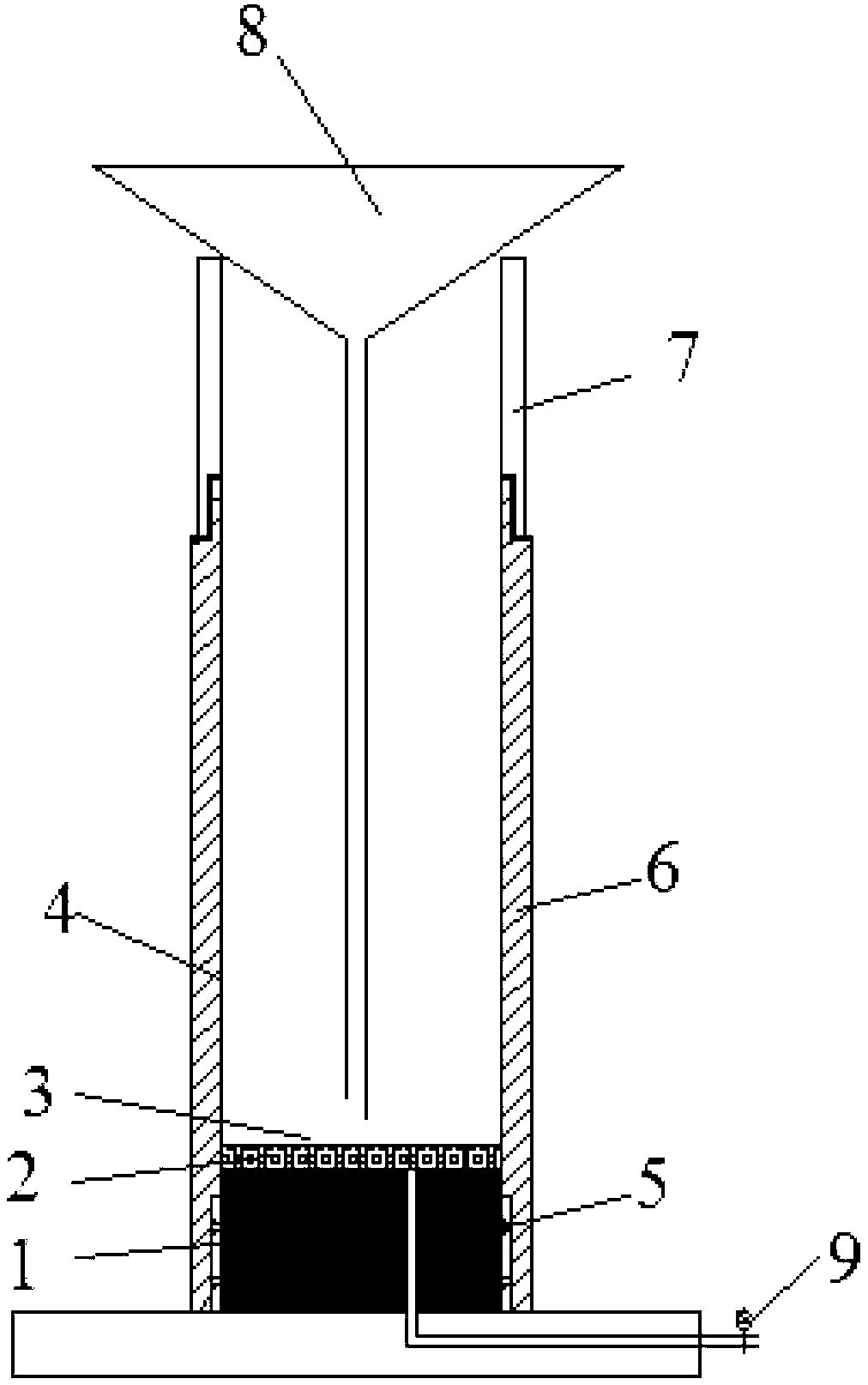

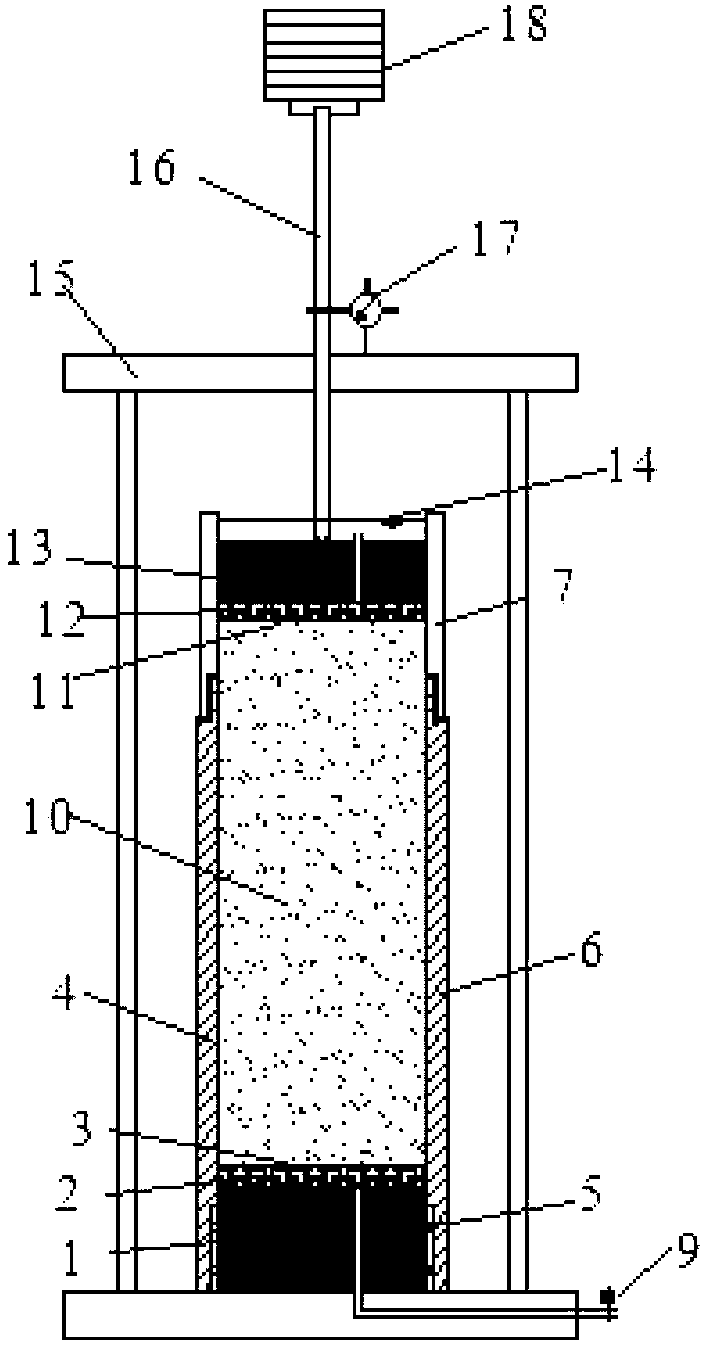

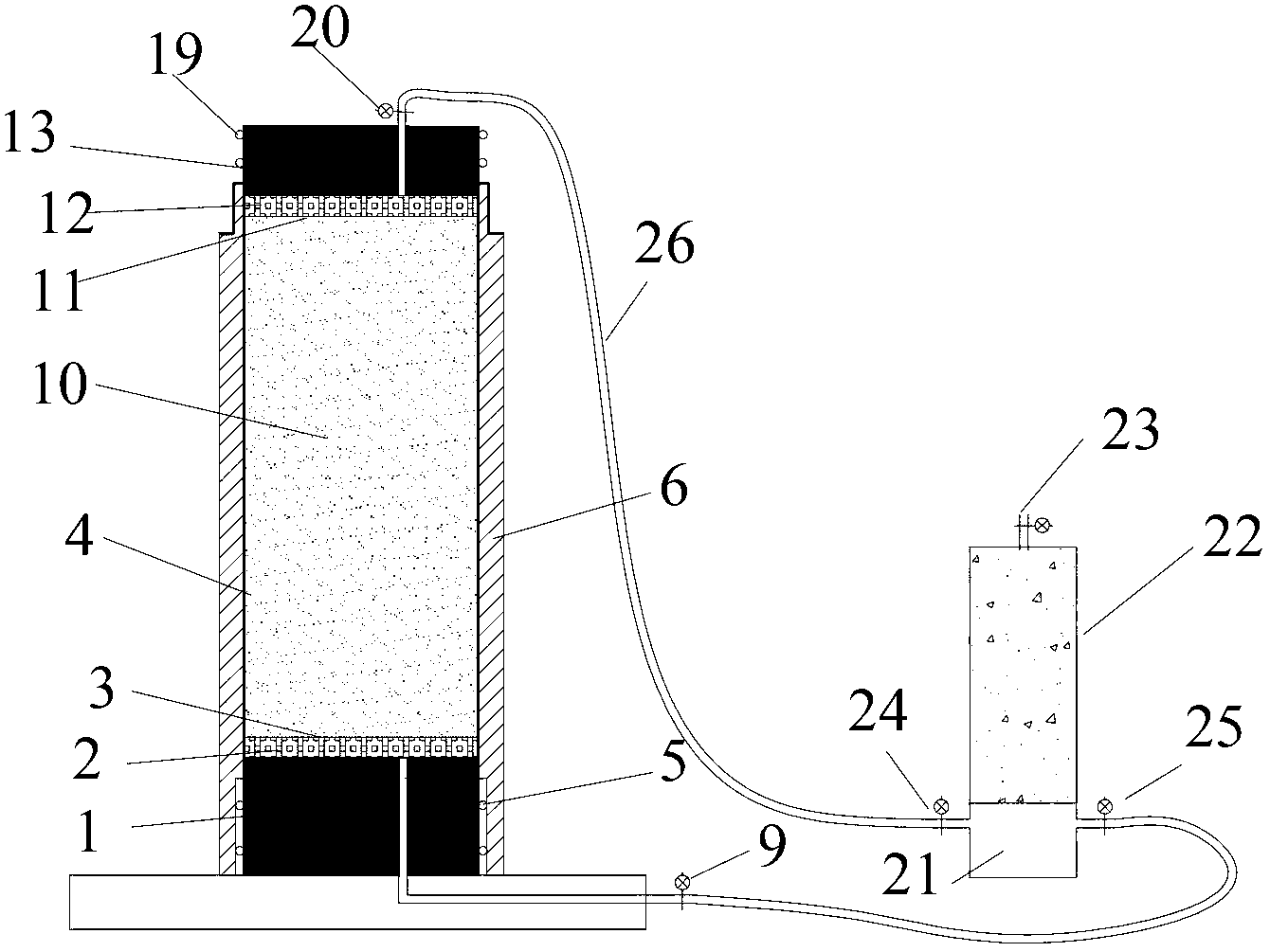

[0016] The preparation method of the silt triaxial test sample provided in this paper is to add enough water to the silt so that the water content is 1.5 times the liquid limit, and then use an automatic mixer to stir the soil sample at a low speed to make the soil sample into a flow-plastic state; Pour the mud into the split round mold (two pieces of synthesis) placed on the base of the triaxial instrument. The split round mold is covered with rubber film, permeable stone and filter paper; let the soil sample settle under the action of its own weight, in order to ensure that the upper layer of water does not volatilize, seal the upper layer of water with a plastic film; add a dead load on the upper part of the sample, in order to ensure that the mud does not overflow, load slowly and gradually, and add the next level of load aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com