Copper-clad aluminum alloy composite conducting wire and preparation method thereof

A copper-clad aluminum alloy, composite wire technology, applied in metal/alloy conductors, cable/conductor manufacturing, electrical components, etc., can solve the problems of decreased electrical conductivity and increased strength difference of surface copper materials, achieving low production cost, Flexible production, excellent mechanical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

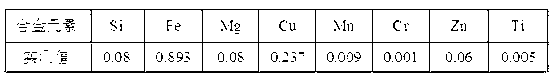

[0025] According to the chemical composition range of the aluminum alloy designed in the present invention, 99.7% aluminum ingots, magnesium ingots and Al-Cu, Al-Fe master alloys are used to prepare aluminum alloys according to the design mass ratio and feeding rules, and melted in a 500Kg capacity gas-fired smelting furnace. After degassing and slag refining, heat preservation and on-line filtration, the chemical composition of the melt sample was analyzed by direct spectral reading method, and the measured composition is shown in Table 1.

[0026]

[0027] The measured chemical composition / wt% of table 1 aluminum alloy of the present invention

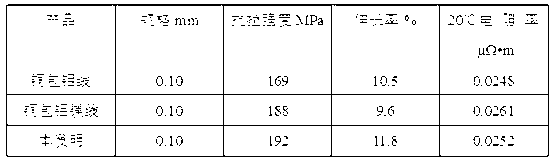

[0028] After heat preservation and filtration, it is cast into a round wire rod with a diameter of Ф12mm by a horizontal continuous casting process with 10 molds. The pouring temperature is 700-720°C and the horizontal continuous casting speed is 1100mm / min. After cleaning, rinsing and drying, the rod billet i...

Embodiment 2

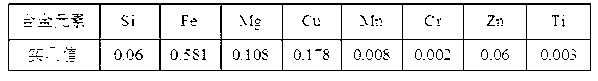

[0035] According to the chemical composition range of the aluminum alloy designed in the present invention, 99.7% aluminum ingots, magnesium ingots and Al-Cu, Al-Fe master alloys are used to prepare aluminum alloys according to the design mass ratio and feeding rules, and melted in a 500Kg capacity gas-fired smelting furnace. After degassing and slag refining, heat preservation and on-line filtration, the chemical composition of the melt sample was analyzed by direct spectral reading method. The measured composition is shown in Table 3.

[0036]

[0037]

[0038] The measured chemical composition / wt% of table 3 aluminum alloy of the present invention

[0039] After heat preservation and filtration, it is cast into a round wire rod with a diameter of Ф12mm by a horizontal continuous casting process with 10 molds. The pouring temperature is 690-710°C and the horizontal continuous casting speed is 900mm / min. After cleaning, rinsing and drying, the rod billet is extruded into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com