Airtightness packaging radiating structure of integrated circuit

A technology of integrated circuits and heat dissipation structures, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as electrical performance degradation, excessive chip temperature rise, and functional failure, and achieve excellent air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

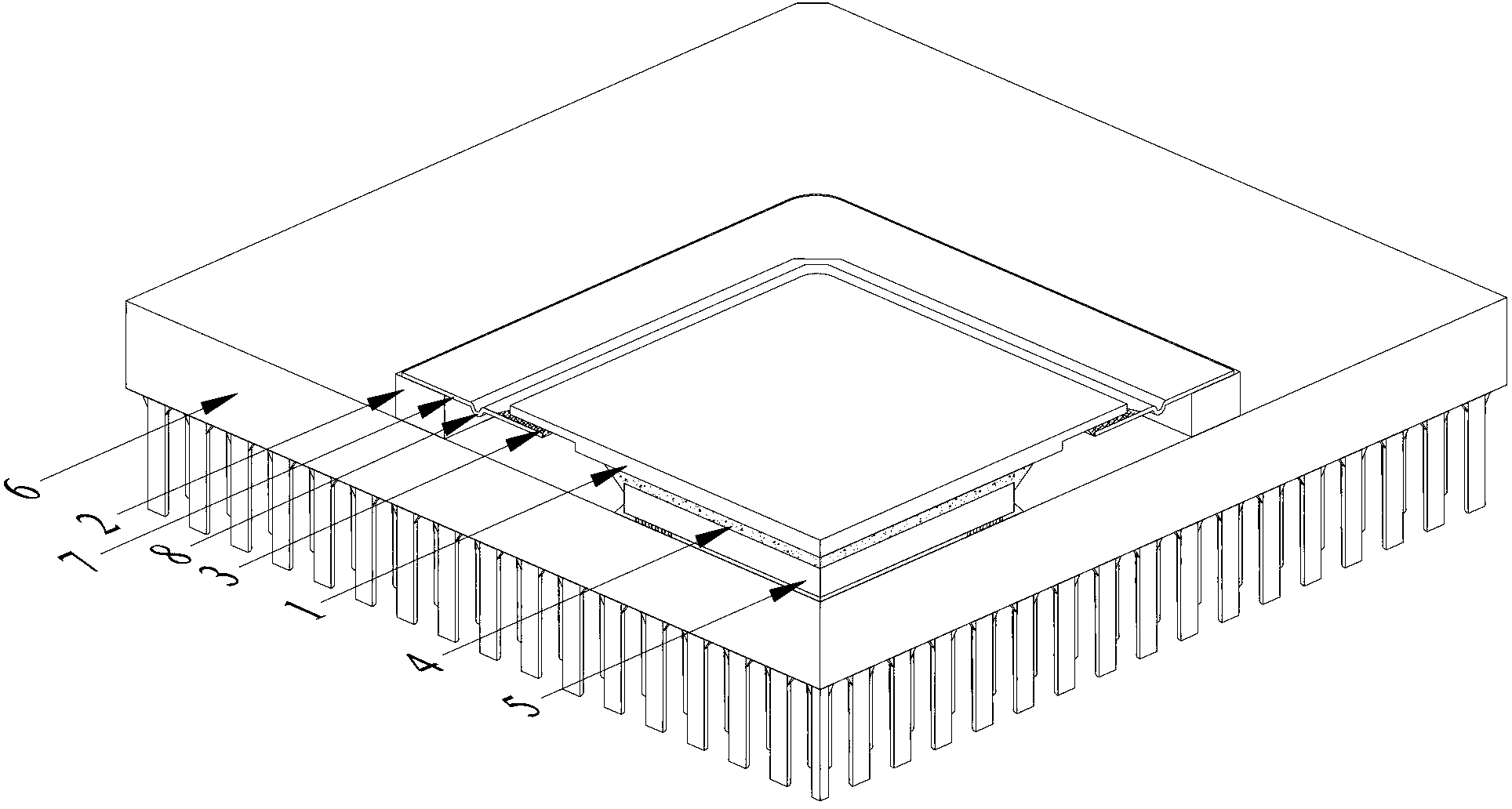

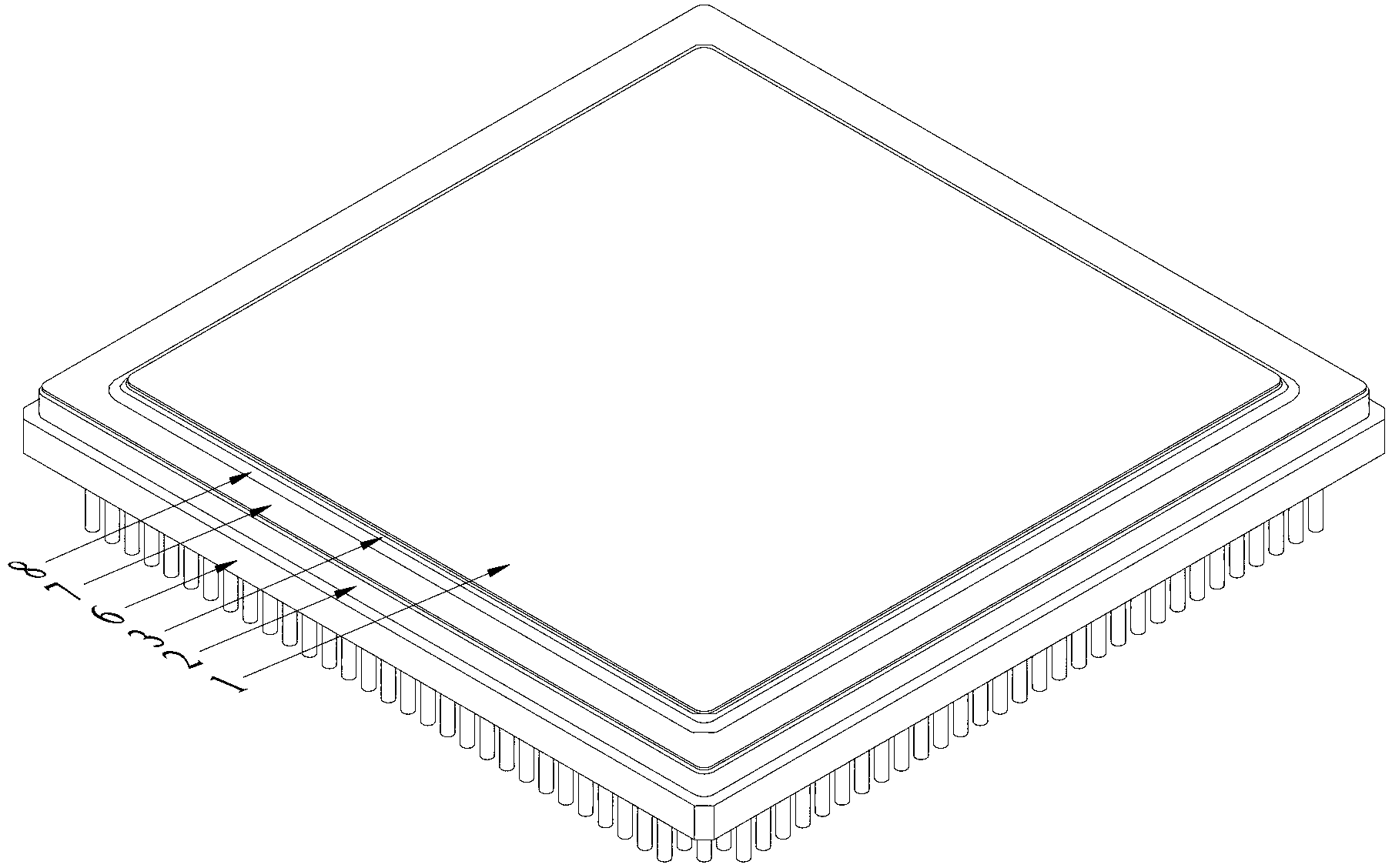

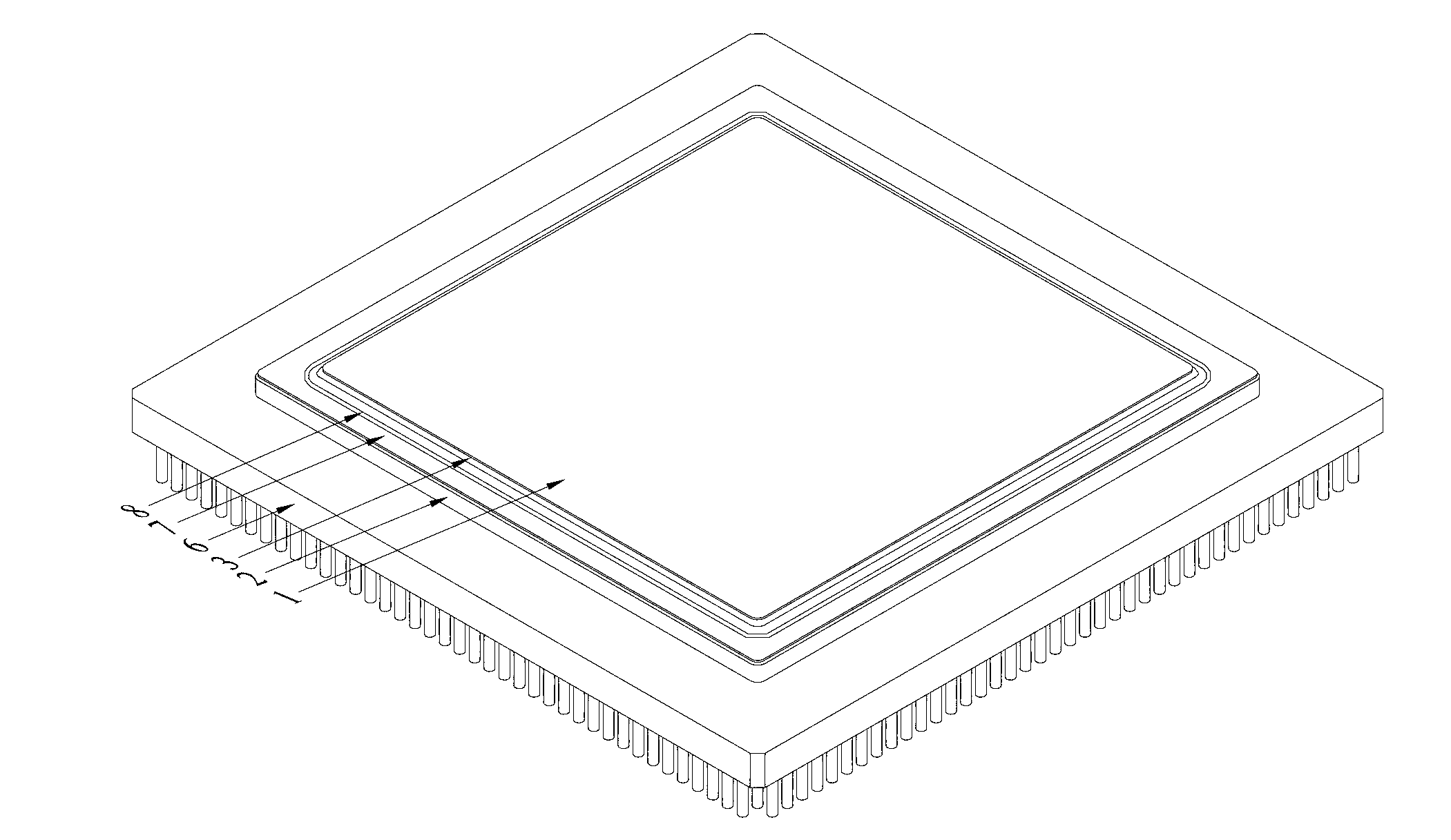

[0015] Such as figure 1 As shown, the heat dissipation structure of the present invention adopts a high thermal conductivity metal heat sink 1 that matches the thermal expansion base of the shell / substrate, and is brazed together with a welding frame 7 made of materials such as Kovar through brazing material 3; the heat sink 1 Weld together with soft solder 4 and metallized upside-down soldering chips 5; finally weld the welding frame 7 and the sealing ring 2 on the shell or substrate 6 together by laser welding, parallel seam welding, etc. to form an airtight The heat sink 1 can efficiently conduct the heat of the chip to the cold plate, etc., forming an excellent thermal channel. A circle of grooves can be set on the welding frame 2 to form a buffer ring 8 around the heat sink 1 .

[0016] In the integrated circuit airtight heat dissipation structure of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com