A kind of metal and crystal hermetically encapsulated light window structure manufacturing method

A manufacturing method and air-tight technology, applied in manufacturing tools, metal processing equipment, measuring devices, etc., can solve problems such as short service life, organic adhesives that are not resistant to high temperatures, and reduce the reliability of packaging components, so as to avoid technical difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the present invention more concise and clear, the present invention is described with the following specific examples, but the present invention is by no means limited to these examples. The following descriptions are only preferred embodiments of the present invention, and are only used to describe the present invention, and should not be construed as limiting the scope of the present invention. It should be noted that any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention shall be included within the protection scope of the present invention. Therefore, the protection scope of the patent for the present invention should be based on the appended claims.

[0030] The experimental results of low temperature glass or epoxy resin encapsulation in the prior art are shown in Table 1:

[0031]

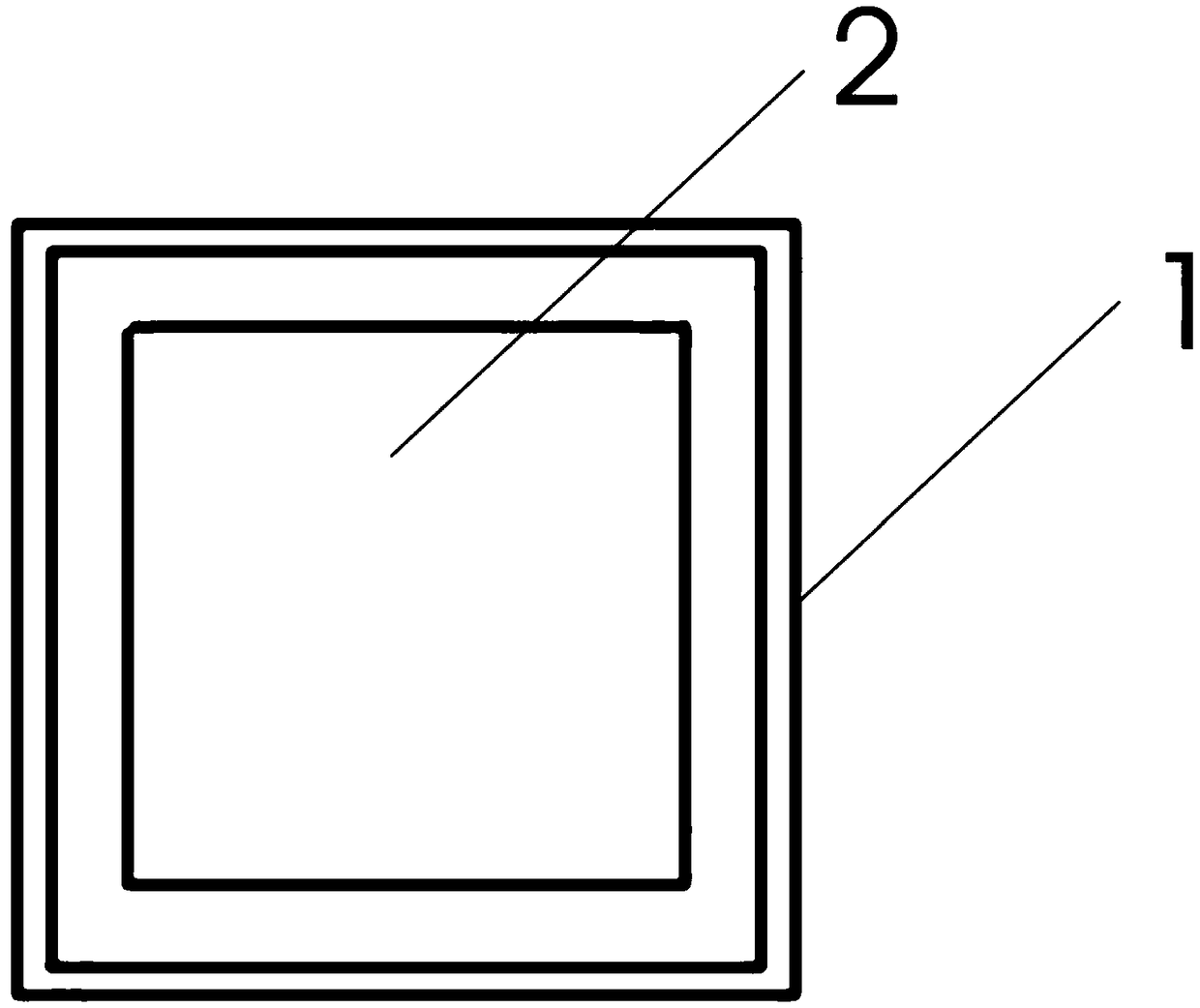

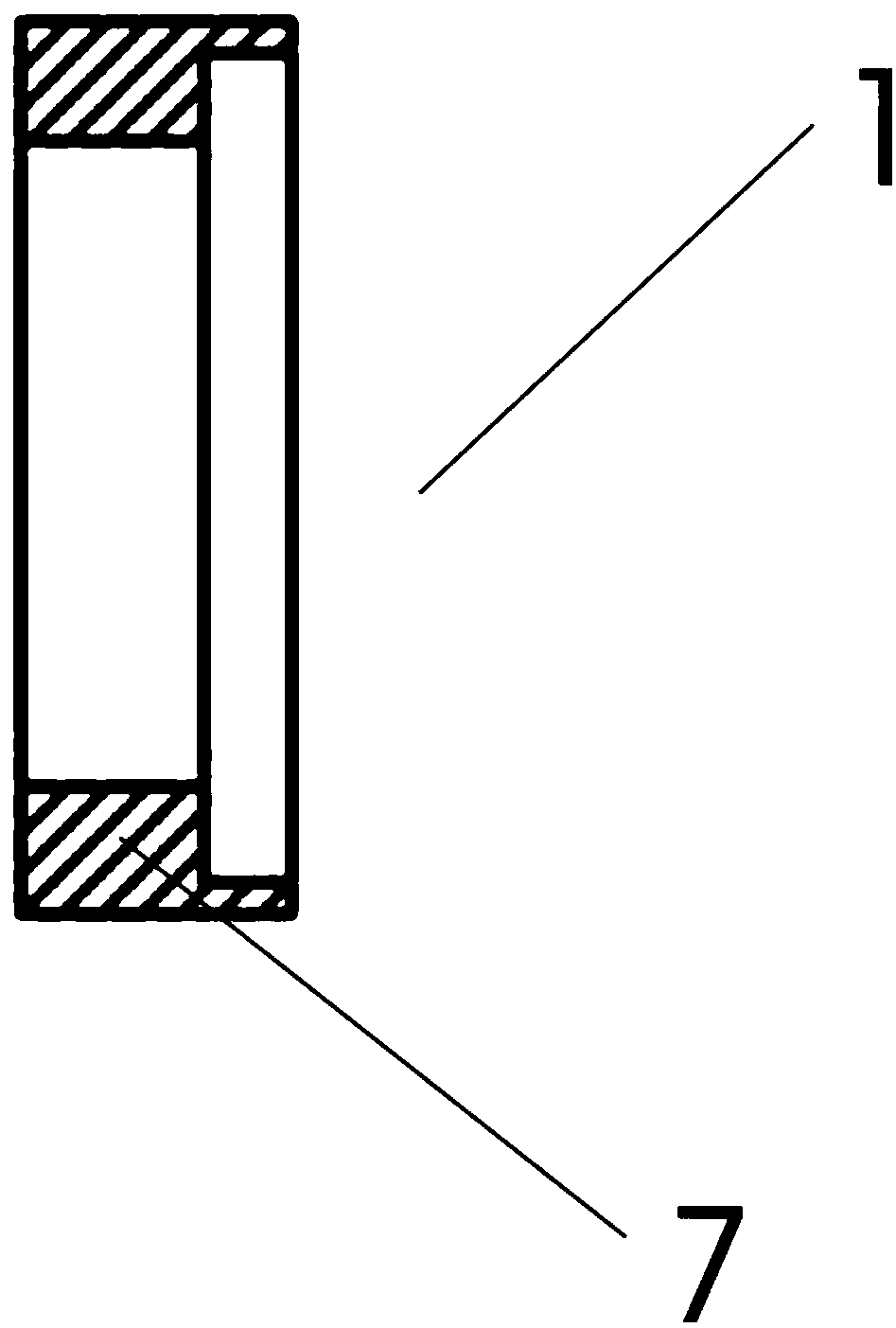

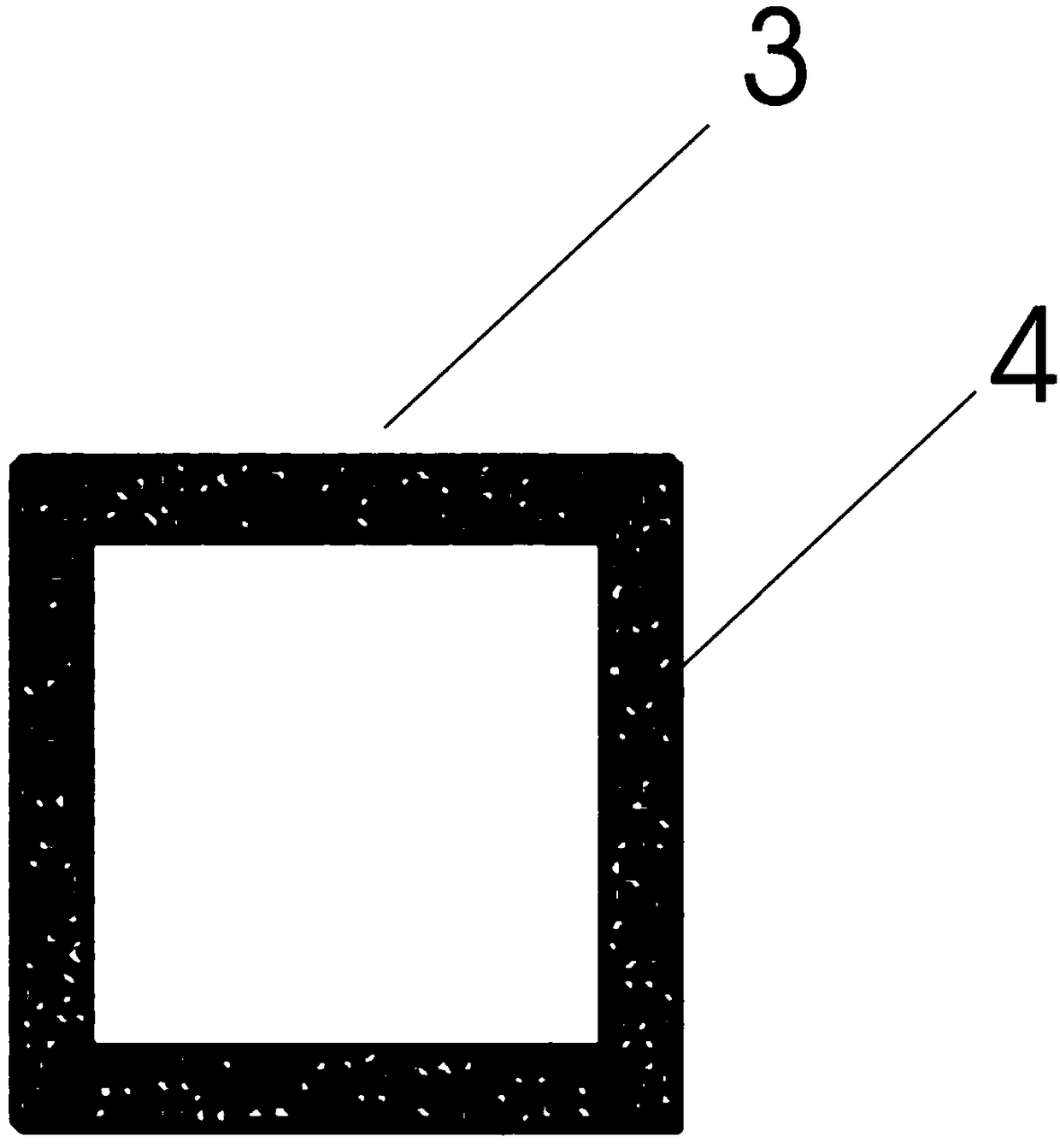

[0032] See Figure 1-7 , the number 1 repr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com