Metallization process and welding method for pyrolytic graphite

A technology of pyrolytic graphite and process method, which is applied in the direction of metal material coating process, metal processing equipment, welding equipment, etc. to achieve the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

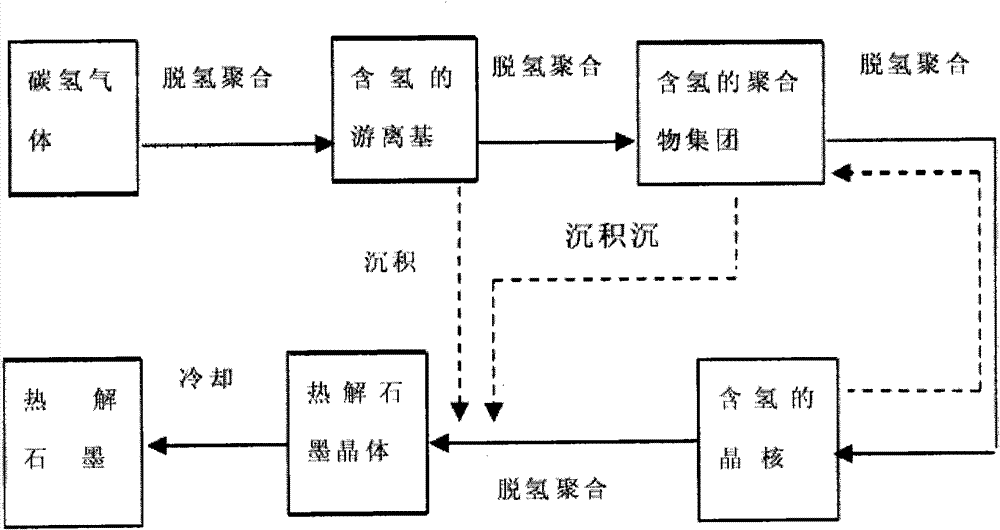

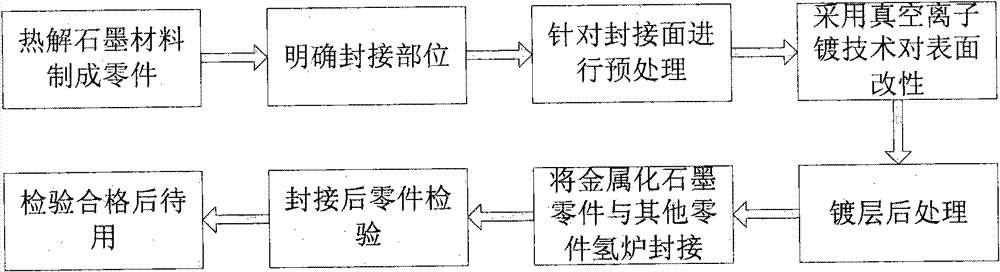

Method used

Image

Examples

Embodiment

[0056] 1. Pretreatment of pyrolytic graphite substrate:

[0057] 1) Grinding with 500-mesh metallographic sandpaper, ultrasonic cleaning with alcohol for 3 minutes, and dehydration with acetone;

[0058] 2) Vacuumize to make the vacuum degree in the multi-arc vacuum ion plating tank reach 9×10 -3 Pa;

[0059] 3) Glow cleaning: Ar gas, bias voltage 1000V, add 1 minute;

[0060] 4) Perform ion bombardment cleaning: Ar gas, negative bias voltage 400V, 1 minute;

[0061] 2. Carry out the deposition of transition film layer (Cr layer) and surface film layer (Ni layer):

[0062] 1) Cr film deposition, using parameters: voltage 200V, 20 minutes;

[0063] 2) Ni film deposition, using parameters: voltage 150V, 40 minutes;

[0064] 3. Post-treatment of the coating:

[0065] 1) In a hydrogen furnace, heat up to 950°C at a heating rate of 10°C / min, hold for 5 minutes, and then cool with the furnace;

[0066] 2) After being out of the oven, the plated parts need to be stored in a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com