Method for implementing light emitting diode surface pattern preparation by using two-beam interference for assisting wet etching

A technology of light-emitting diodes and double-beam interference, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of window layer structure damage, complex process, p-GaP surface damage, etc., to improve speed, simple operation, and applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

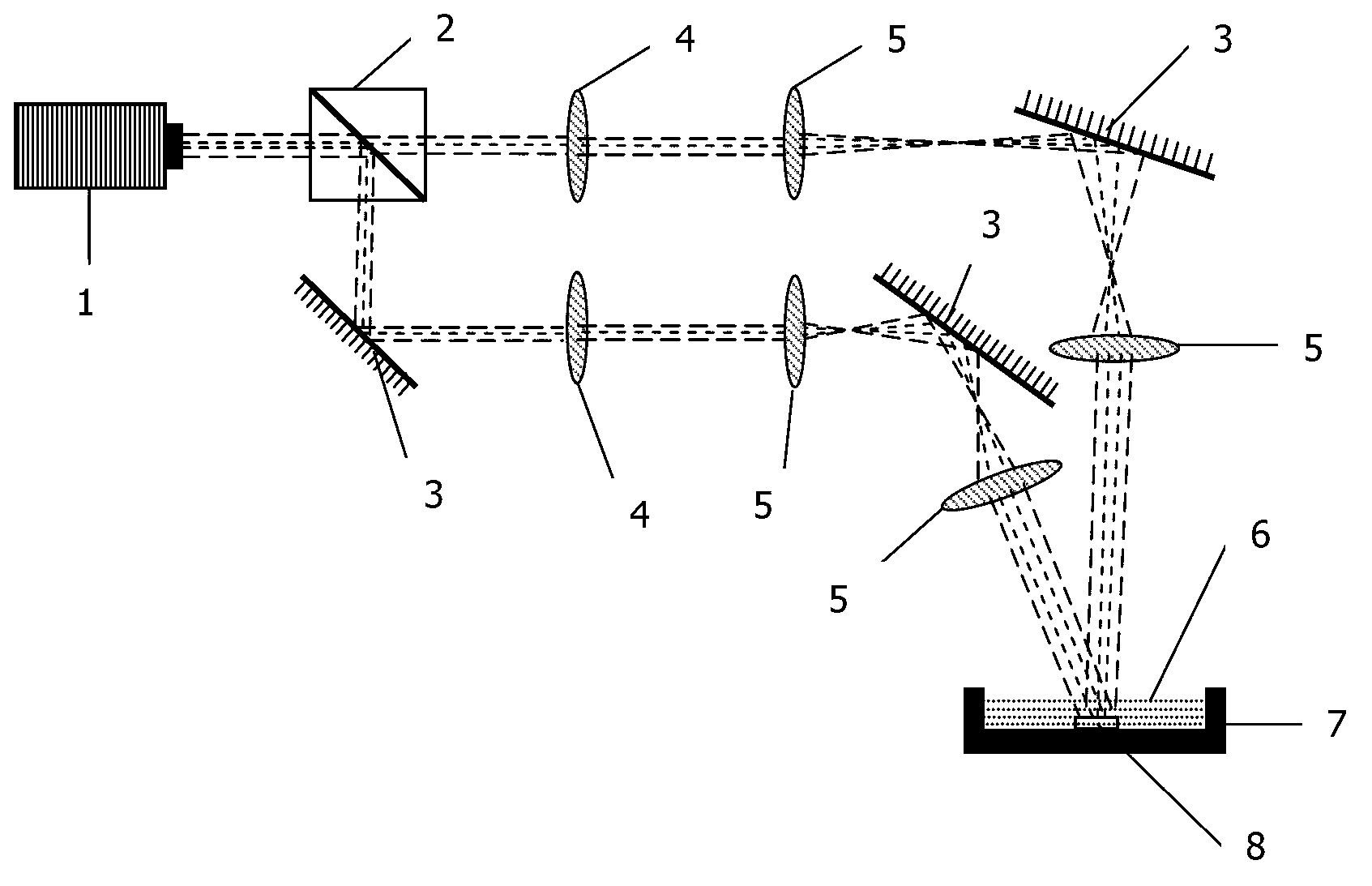

[0048] like Figure 1-Figure 5 shown.

[0049] A method for preparing surface patterns of light-emitting diodes by using double-beam interference-assisted wet etching. Taking the surface pattern preparation of AlGaInP red light-emitting diode epitaxial wafers as an example, the steps are as follows:

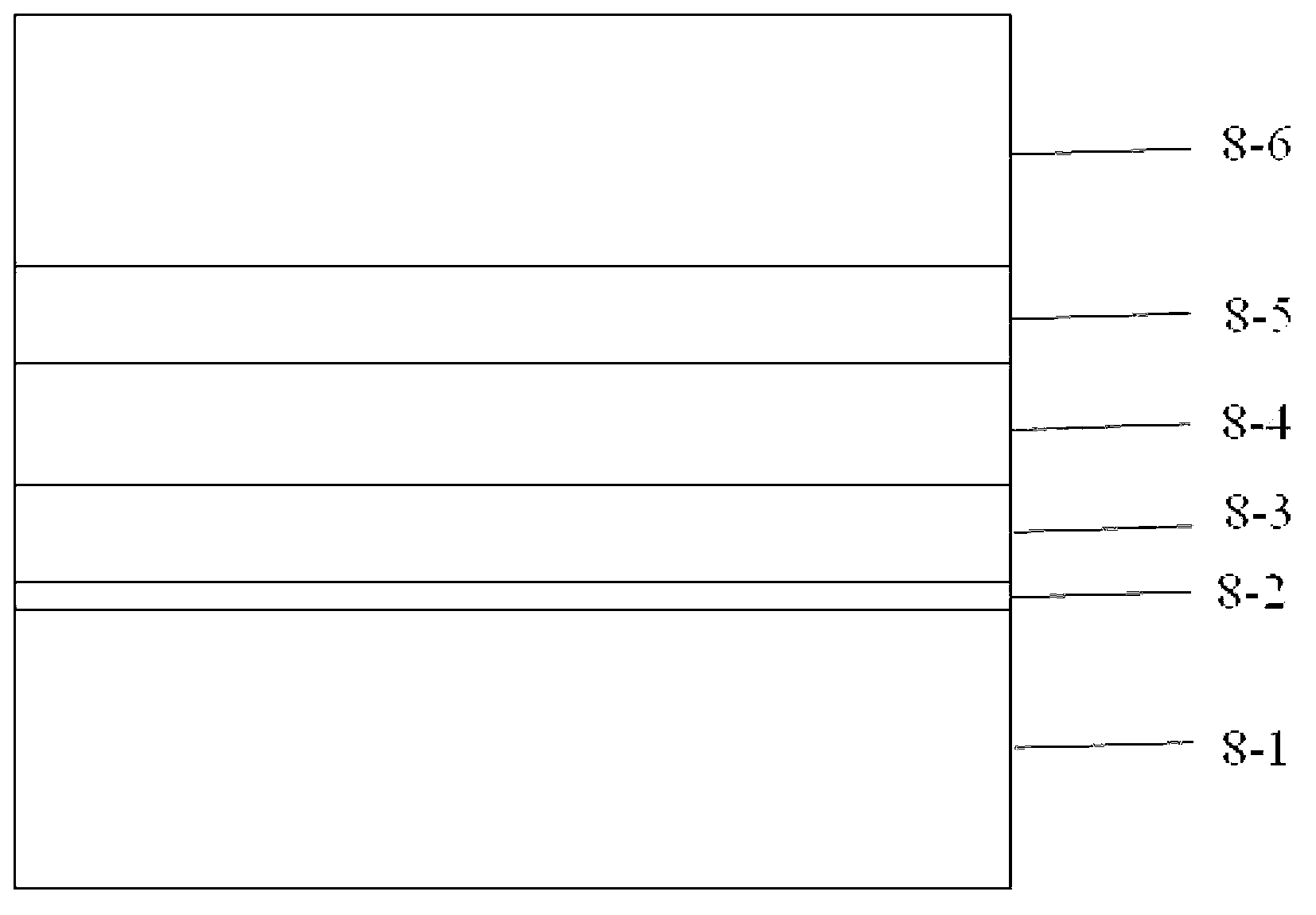

[0050] (1) Growth of red light-emitting diode epitaxial wafer 8: using metalorganic chemical vapor deposition (MOCVD) to sequentially grow Bragg reflector 8-2 and n-type aluminum gallium indium phosphorus layer 8-3 on GaAs substrate 8-1 , multi-quantum well layer 8-4, p-type aluminum gallium indium phosphide layer 8-5 and p-type GaP layer 8-6, prepared into a red light emitting diode epitaxial wafer;

[0051] (2) Adjust the interference light path:

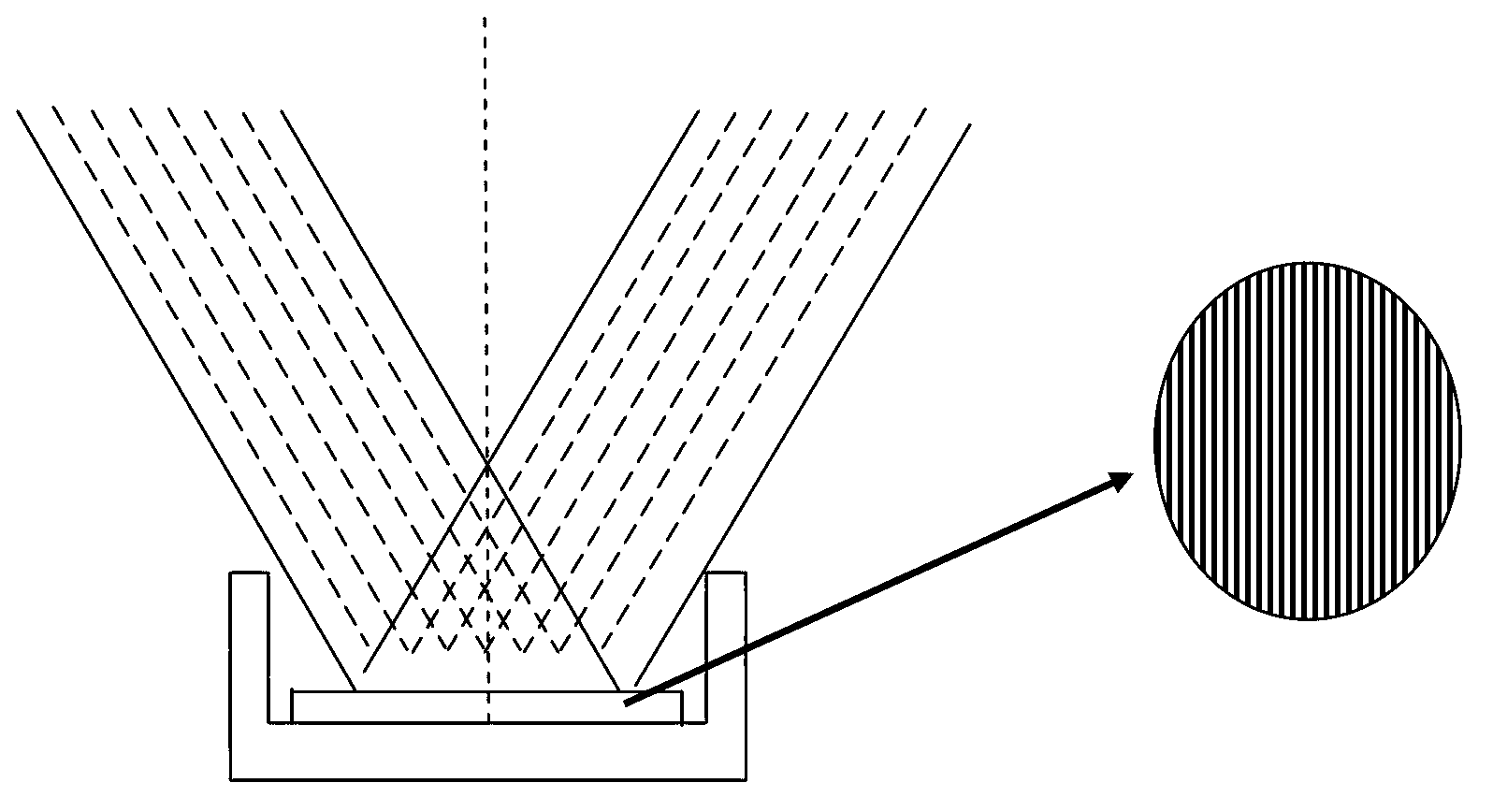

[0052] Put the red light-emitting diode epitaxial wafer 8 into a polytetrafluoroethylene flat-bottomed container 7, add deionized water to cover the surface to be etched (i.e. the p-type GaP layer) of the red light-emitting diode e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com