Method for repairing demineralized dentin

An essential, mineral-based technology, used in dentistry, dental preparations, dental prostheses, etc., to achieve the effects of easy availability of raw materials, recovery of mineral content, and recovery of super mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

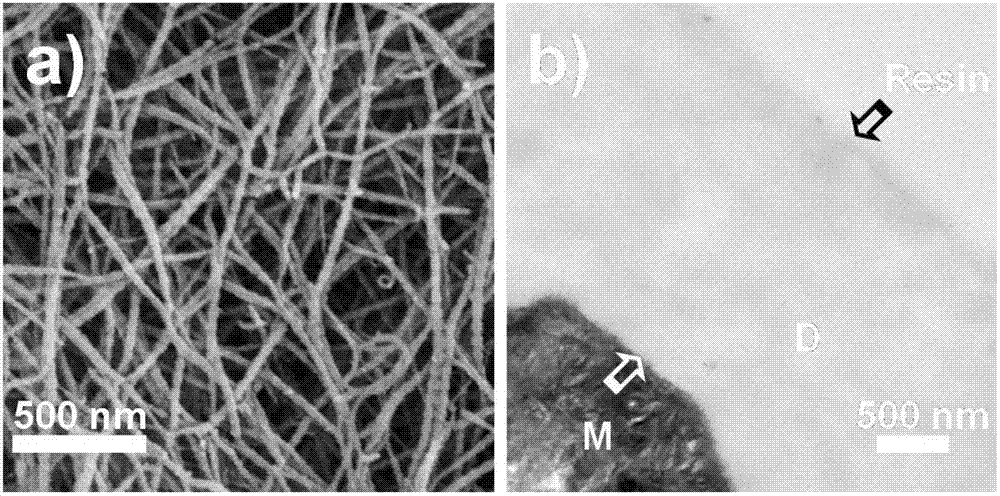

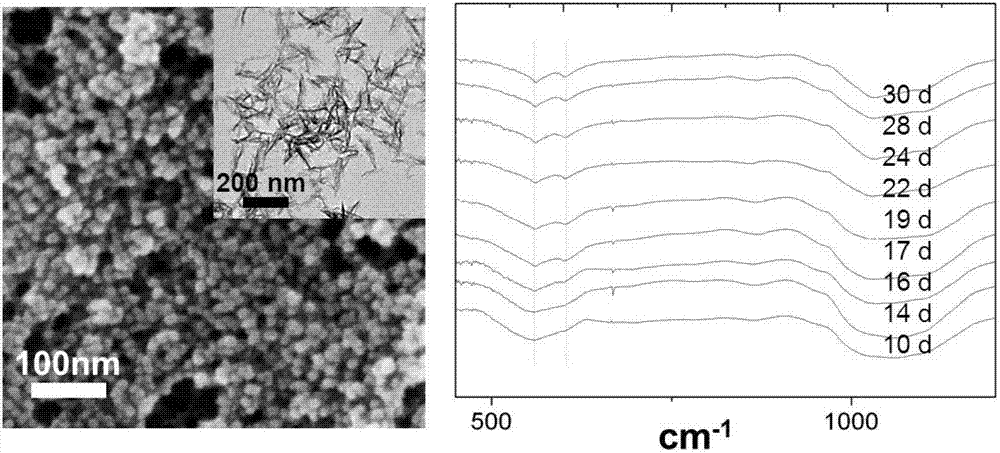

[0023] Equipped with 0.25M calcium chloride (CaCl 2 ) aqueous solution, 0.15M disodium hydrogen phosphate (Na 2 HPO 4 ) aqueous solution, 10g / L polyacrylic acid (PAA) aqueous solution was used as the mother liquor for the synthesis experiment. Take 2.4 mL of Na 2 HPO 4 Mix the mother liquor and 2.0mL of PAA mother liquor, dilute with twice distilled water, adjust the pH to 9.5±0.1 with 1M NaOH aqueous solution, stir at room temperature for 0.5h, and the total volume is 30mL. Take 2.4mL CaCl 2 Dilute the mother liquor with water to 30mL. Use a burette to add 30mL of calcium solution 30 to 30mL of phosphorus solution, stir with a magnetic stirrer during the dropwise addition, and adjust the pH with 0.1M NaOH solution to keep it in the range of 9.5±0.5. Finally, the calcium ion concentration was 10.0mM, the phosphorus ion concentration was 6.0mM, and the PAA concentration was 300ug / mL. Ensure that the entire dropping process lasts for 25 to 30 minutes. To collect caries-...

Embodiment 2

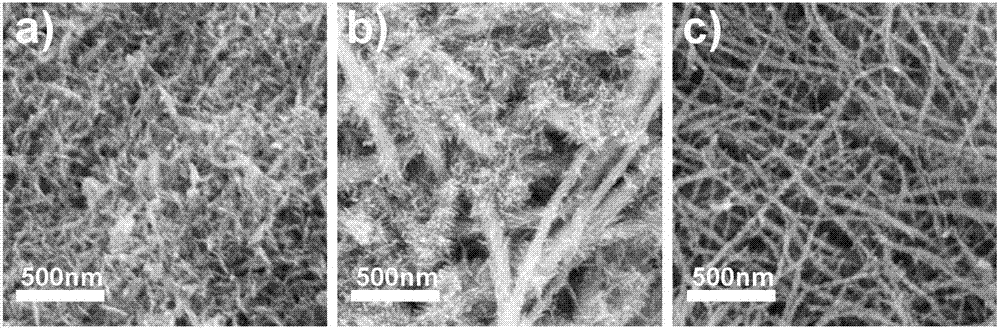

[0025] Equipped with 0.25M calcium chloride (CaCl 2 ) aqueous solution, 0.15M disodium hydrogen phosphate (Na 2 HPO 4 ) aqueous solution, 10g / L polyacrylic acid (PAA) aqueous solution was used as the mother liquor for the synthesis experiment. Take 2.4 mL of Na 2 HPO 4 Mix the mother liquor with 3.0mL of PAA mother liquor, dilute with double distilled water, adjust the pH to 9.5±0.1 with 1M NaOH aqueous solution, stir at room temperature for 0.5h, and the total volume is 30mL. Take 2.4mL CaCl 2 Dilute the mother liquor with water to 30mL. Use a burette to add 30 mL of calcium solution 30 to 30 mL of phosphorus solution, stir with a magnetic stirrer during the dropwise addition, and keep the pH in the range of 9.5±0.5 by adjusting the pH with 0.1M NaOH solution. Finally, the calcium ion concentration was 10.0 mM, the phosphorus ion concentration was 6.0 mM, and the PAA concentration was 500 ug / mL. Ensure that the entire dropping process lasts for 25 to 30 minutes. To co...

Embodiment 3

[0027] Equipped with 0.25M calcium chloride (CaCl 2 ) aqueous solution, 0.15M disodium hydrogen phosphate (Na 2 HPO 4 ) aqueous solution, 10g / L polyacrylic acid (PAA) aqueous solution was used as the mother liquor for the synthesis experiment. Take 2.4 mL of Na 2 HPO 4 Mix the mother liquor with 6.0mL of PAA mother liquor, dilute with twice distilled water, adjust the pH to 9.5±0.1 with 1M NaOH aqueous solution, stir at room temperature for 0.5 h, and the total volume is 30 mL. Take 2.4mL CaCl 2Dilute the mother liquor with water to 30mL. Use a burette to add 30 mL of calcium solution 30 to 30 mL of phosphorus solution, stir with a magnetic stirrer during the dropwise addition, and keep the pH in the range of 9.5±0.5 with 0.1M NaOH solution. The final concentrations of calcium ions and phosphorus ions were 10.0 mM and 6.0 mM, respectively. Finally, the calcium ion concentration was 10.0 mM, the phosphorus ion concentration was 6.0 mM, and the PAA concentration was 1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com