Long-acting catalyst for preparing styrene by ethylbenzene dehydrogenation and preparing method thereof

An ethylbenzene dehydrogenation production and catalyst technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of high material consumption and high energy consumption in styrene production , the service life of the catalyst is not long enough, etc., to achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

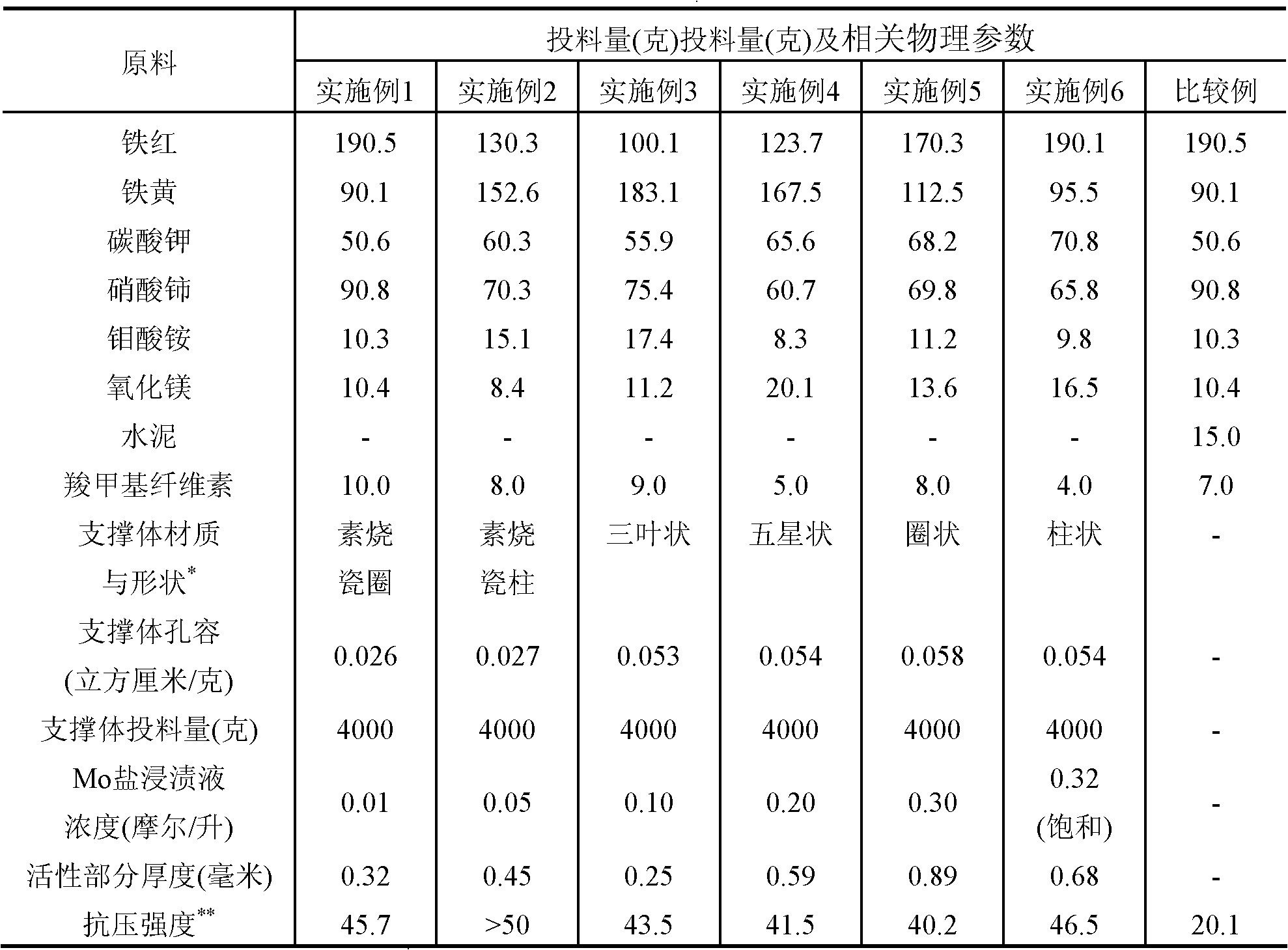

[0039]190.5 grams of iron oxide red, 90.1 grams of iron oxide yellow, 50.6 grams of potassium carbonate, 90.8 grams of persimmon nitrate, 10.3 grams of ammonium molybdate, 10.4 grams of magnesium oxide and carboxymethyl cellulose were stirred in a kneader for 1 hour, and an appropriate amount was added to remove Ionized water, and then stir for half an hour to make a slurry and take it out. At room temperature, add 4000 grams of support B impregnated by 0.01 mol / L ammonium molybdate solution to the slurry and stir evenly to form a uniform coating by A The catalyst particles were put into an oven and baked at 40°C for 3 hours, then placed in a muffle furnace and calcined at 800°C for 2 hours to prepare the catalyst.

Embodiment 2~6

[0041] Catalysts were prepared according to the conditions and operating steps of Example 1, except that the dosage of active components, the shape of the support, materials, etc. were changed, as shown in Table 1.

Embodiment 7~13

[0049] Soak the bisque ceramic ring at different temperatures and different Mo salt concentrations for different times, and after drying, evenly coat the active component slurry of Example 1, put it in an oven to dry, and then put it in a muffle furnace for firing. See Table 2 for the pretreatment conditions of the support body and the catalyst precursor and the thickness and compressive strength of the active components of the finished catalyst:

[0050] Table 2 The pretreatment conditions of the support and the relevant physical parameters of the catalyst prepared after coating the active component

[0051]

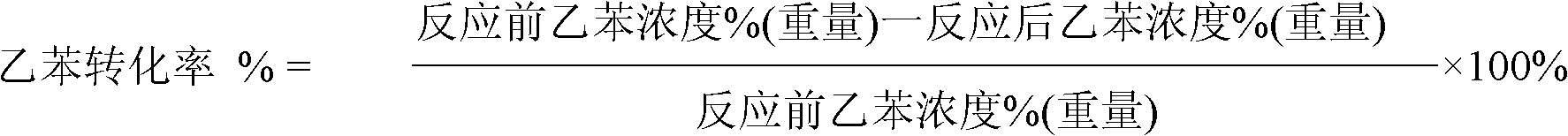

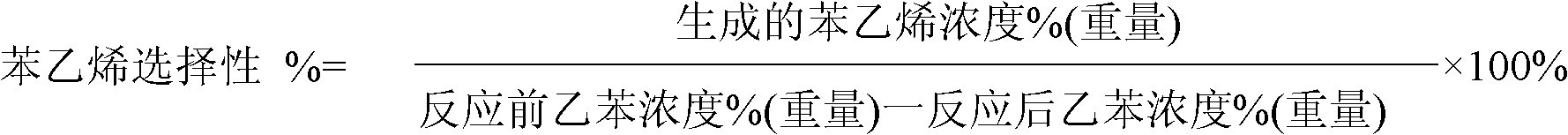

[0052] The catalysts obtained in Examples 1 to 13 and Comparative Example 1 were put into an isothermal reactor with an inner diameter of 1 "respectively, and the reaction pressure was normal pressure and the liquid space velocity was 1.0 hour -1 , the reaction temperature was 620°C, and the water / ethylbenzene weight ratio was 2.0, and the catalytic performance of et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com