Method for forming biological titanium alloy oxide films through cutting processing

A technology of cutting processing and oxide film, applied in the field of cutting processing, can solve the problems of low cost, complex process equipment, short process chain, etc., and achieve the effect of avoiding chloride ion damage, simple process equipment, and short process chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

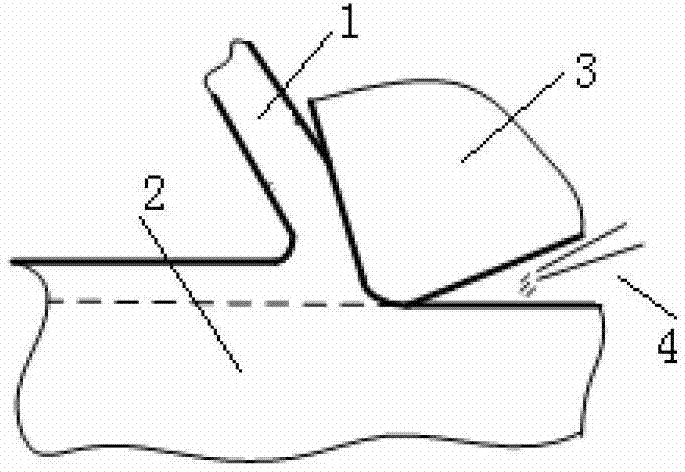

[0024] like figure 1 As shown, the turning process, the outer surface of the TC4 cylinder is turned, the lathe is a PUMA 200M lathe, and the cutting temperature is measured by an infrared thermometer. The workpiece 2 is processed by the tool 3 in an oxygen-enriched atmosphere 4 to cut off chips 1 .

[0025] (1) When finishing machining, determine reasonable cutting parameters, and optimize cutting parameters through finite element simulation according to the machining allowance and cutting tool, using cutting machining theory and numerical simulation method: cutting speed 120m / min, back cutting amount 0.25mm, feed rate 0.1mm / r;

[0026] (2) Detect the cutting temperature of the cutting process, and measure the surface temperature of the workpiece through the infrared thermal imager;

[0027] (3) During the finishing process, an oxygen-rich atmosphere is applied during the cutting process. In order to increase the density of the oxide film and reduce the difficulty of oxide f...

Embodiment 2

[0031] Turning as figure 1 As shown, the turning process, the outer surface of the TC4 cylinder is turned, the lathe is a PUMA 200M lathe, and the cutting temperature is measured by an infrared thermometer. The workpiece 2 is processed by the tool 3 in an oxygen-enriched atmosphere 4 to cut off chips 1 .

[0032] (1) When finishing machining, determine reasonable cutting parameters, and optimize cutting parameters through finite element simulation according to the machining allowance and cutting tool, using cutting machining theory and numerical simulation method: cutting speed 120m / min, back cutting amount 0.25mm, feed rate 0.1mm / r;

[0033] (2) Detect the cutting temperature of the cutting process, and measure the surface temperature of the workpiece through the infrared thermal imager;

[0034] (3) An oxygen-enriched atmosphere is applied during the finishing cutting process. In order to increase the density of the oxide film and reduce the difficulty of oxide film format...

Embodiment 3

[0038] like figure 1 As shown, the turning process, the outer surface of the TC4 cylinder is turned, the lathe is a PUMA 200M lathe, and the cutting temperature is measured by an infrared thermometer. The workpiece 2 is processed by the tool 3 in an oxygen-enriched atmosphere 4 to cut off chips 1 .

[0039] (1) When finishing machining, determine reasonable cutting parameters, and optimize cutting parameters through finite element simulation according to the machining allowance and cutting tool, using cutting machining theory and numerical simulation method: cutting speed 120m / min, back cutting amount 0.25mm, feed rate 0.1mm / r;

[0040] (2) Detect the cutting temperature of the cutting process, and measure the surface temperature of the workpiece through the infrared thermal imager;

[0041](3) An oxygen-enriched atmosphere is applied during the finishing cutting process. In order to increase the density of the oxide film and reduce the difficulty of oxide film formation, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com